Vessel rotation leads to loss of position

- DP Event

- Published on 29 November 2019

- Generated on 15 July 2025

- DPE 04/19

- 4 minute read

Incident

Jump to:

A DP2 ROV support vessel was working close to a metrological (met) mast within a wind farm.

Overview

With ROV work completed, the project instructed the vessel to be relocated from the East to the West side of the mast for further ROV duties.

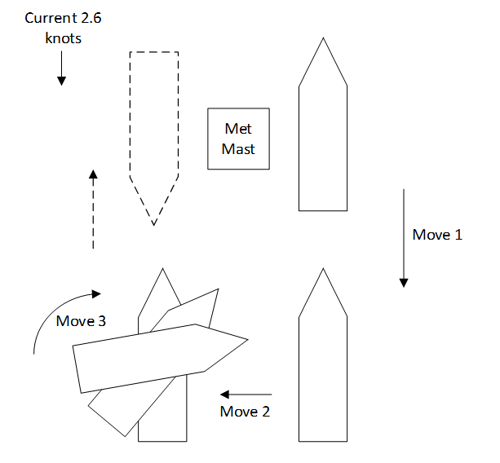

The current at the time of the event was around 2.6 knots, and this value was known to exceed the vessel’s station keeping capability at angles approaching 90 degrees to the beam. As a result, the bridge team conducted an assessment of the risks and concluded that the move could be safely conducted away from the met mast structure in a drift off location making the turn using joystick control.

The vessel commenced relocating, moving astern on automatic DP control to clear the met mast to a safe position downstream (move 1). At that location, the vessel was then manoeuvred transversely to port on automatic DP control (move 2). At the end of this movement, the DPO commenced rotating the vessel through 180 degrees at a rate of turn of 40 degrees per minute using joystick control (move 3). In preparation for the vessel rotation, the DP operator did not change control to full joystick, electing instead to disable ‘auto yaw’ whilst leaving ‘auto surge’ and ‘auto sway’ enabled. Although not understood by the DPO at the time, this effectively meant that the DP system was still set to maintain a setpoint. Thruster loads began to increase as the beam of the vessel became perpendicular to the current. This resulted in the position set point alarm, DP overload alarm, thrust reduction alarms, and the loss of the starboard power system (50% of thrust capability), leading to a total loss of station keeping control.

The master of the vessel took manual control and manoeuvred the vessel away from the wind farm using the remaining thrusters, and eventually, when they had been restarted, the thrusters that had been lost.

Lessons learned

- The investigation noted that whilst the senior DPO was qualified and experienced, the individual was new to the vessel and vessel operator and was carrying out only the second DP watch on-board.

- At the time of the rotation (move 3), the DPO was alone at the DP desks as the junior DPO was undertaking other bridge activities; this contributed to the incorrect setup of the system prior to manoeuvre being unnoticed and/or unchallenged.

- The overall manoeuvre had been risk assessed with the control modes of operation for each step detailed. However, the selection to joystick mode for move 3 was incorrectly executed by leaving ‘auto surge’ and ‘auto sway’ functions active.

- The vessel crew received additional training on the use and effects of ‘auto surge’ and ‘auto sway’ in high current environments.

- A specific risk assessment procedure has been established for the use of manual and joystick control within windfarm limits where major heading changes are involved. This will include verification of the operational procedures (including system setup) by the master or second senior DPO.

- The investigation also recommended a full review of the vessel’s DP operating manuals, risk assessments and close proximity procedures, to assess if any improvements could be made.

Conclusion

The investigation did not conclude any findings related to the vessel losing power to 50% of its thrusters. There should be no conditions where the DP system can command thrust load such that online equipment is overloaded, leading to power failure. Therefore, questions remain unanswered regarding the setup of the thrust limitation system (blackout preventions) within the DP and power management systems (PMS), and/or the power systems ability to operate at near or full load. Such factors should be analysed within the vessel’s DP FMEA and analysis confirmed through FMEA proving trials and subsequent DP Annual Trials Programmes.

This case study demonstrates the importance of good understanding of the DP system modes of operation, specifically when using a combination of automatic and manual control. The same operation could have been performed in manual or joystick control realising that the vessel would drift with the current.

The case study also highlights the need for planning and risk assessment of the operation. This will ensure that there are enough personnel on the bridge and those operating the equipment are fully aware of its functionality.

Latest DP incidents

-

Complete the job

Whilst connected to a turbine, an alarm was generated on the DP operator station, ‘Unbalanced load on SWBD 1’.

DPE 01/25

16 January 2025

Undesired event

-

How is your alignment?

Loss of the CyScan position reference system generated a reference system failure alarm and moments later the vessel began to lose position with the accompanying alarms.

DPE 01/25

16 January 2025

Incident

-

Beware your centre of rotation

The stern thrusters started to oscillate which transferred to an oscillating motion of the vessel and high forces were being used to try to maintain position.

DPE 01/25

16 January 2025

Incident

-

A-Tension

Whilst pipelaying in shallow water, the vessel experienced a tension sensor failure on one tensioner.

DPE 01/25

16 January 2025

-

DP Drill Scenario

DP emergency drill scenarios are included to assist DP vessel management, DPOs / Engineers, and ETOs in conducting DP drills onboard.

DPE 01/25

16 January 2025

Drill Scenario

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.