Worn components create unwanted thrust

- DP Event

- Published on 25 August 2021

- Generated on 30 June 2025

- DPE 03/21

- 2 minute read

Incident

Jump to:

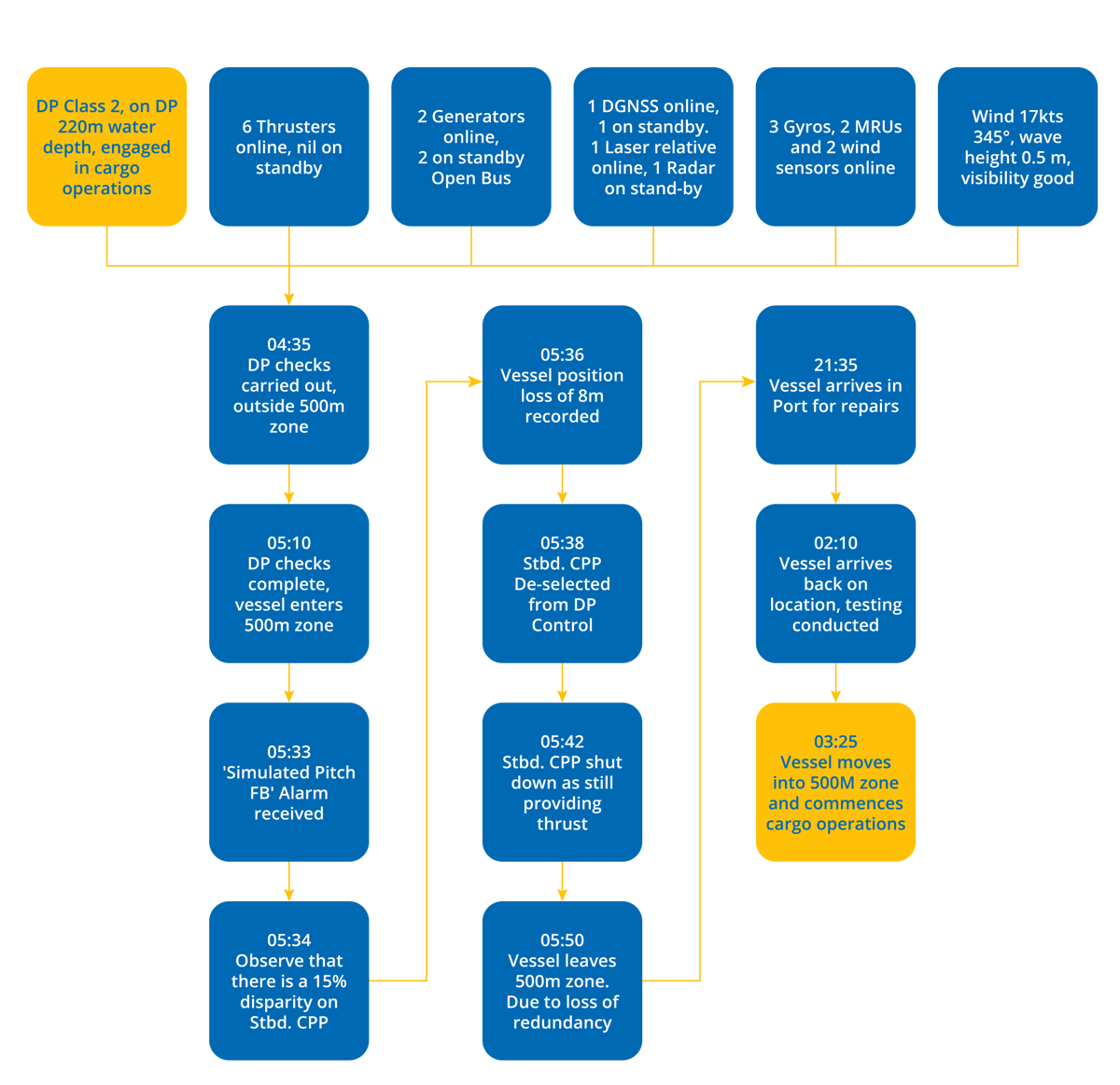

A worn key within the coupling of the step motor caused unwanted travel of the thruster pitch. The vessel was forced to return to port.

Comments

It was found that a worn key within the coupling of the step motor (providing feedback) caused unwanted travel of the thruster pitch. The vessel was forced to return to port to source a spare part, a ‘used but good’ part was located and fitted.

Considerations

- In most direct driven CPP systems there are some failures that can lead to uncontrolled thrust and the

emergency stop needs to be employed by the DPO, before the excursion becomes too significant. DPOs should not hesitate to use the emergency stop on thrusters if thruster alarms indicate a thruster control issue. - Use of a “second hand” part might be acceptable as a temporary stop gap measure, provided that the part is still within specification.

- This event highlights the need to annually check and test controllable pitch propellers.

IMCA M190 Chapter 4.0 Paragraph 4.10:

“There are many ways in which a variable speed thruster can fail, but the failure effects are generally safe. For vessels with variable speed thrusters of proven reliability, it may be acceptable to carry out the control loop wire break tests on a rolling programme where all tests are carried out over a five-year period. Controllable pitch propellers should be tested annually.“ - Although not related to the event, the number of references is inadequate. IMO MSC Circ. 645, IMO MSC.1 Circ. 1580, and IMCA M252, Guidance on position reference systems and sensors for DP operations guidance documents state that for DP 2 or 3 operations:

“There is a requirement for three independent position references based on two different principles to be simultaneously available during operation.”

Latest DP incidents

-

Complete the job

Whilst connected to a turbine, an alarm was generated on the DP operator station, ‘Unbalanced load on SWBD 1’.

DPE 01/25

16 January 2025

Undesired event

-

How is your alignment?

Loss of the CyScan position reference system generated a reference system failure alarm and moments later the vessel began to lose position with the accompanying alarms.

DPE 01/25

16 January 2025

Incident

-

Beware your centre of rotation

The stern thrusters started to oscillate which transferred to an oscillating motion of the vessel and high forces were being used to try to maintain position.

DPE 01/25

16 January 2025

Incident

-

A-Tension

Whilst pipelaying in shallow water, the vessel experienced a tension sensor failure on one tensioner.

DPE 01/25

16 January 2025

-

DP Drill Scenario

DP emergency drill scenarios are included to assist DP vessel management, DPOs / Engineers, and ETOs in conducting DP drills onboard.

DPE 01/25

16 January 2025

Drill Scenario

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.