Lift bags broke free

- Safety Flash

- Published on 4 February 2008

- Generated on 15 February 2026

- IMCA SF 02/08

- 2 minute read

Jump to:

A Member has reported an incident in which lift bags broke free.

What happened?

Two ten-ton airbags had been deflated at the seabed in preparation for being lifted onboard the vessel. During recovery, the airbags broke free while taken through the splashzone. The vessel crew tried to keep visual contact with the air bags when on surface and move the vessel away from them but the air bags disappeared under the vessel and were assumed to have sunk to seabed. Two days later, during transit, the vessel crew saw that a thruster was experiencing increased power consumption and reduced revolutions. An ROV confirmed that one of the lost lift bags was caught in the thruster. The vessel went to port for further investigation and, as a result of an oil leakage in the thruster, had to be docked for repair.

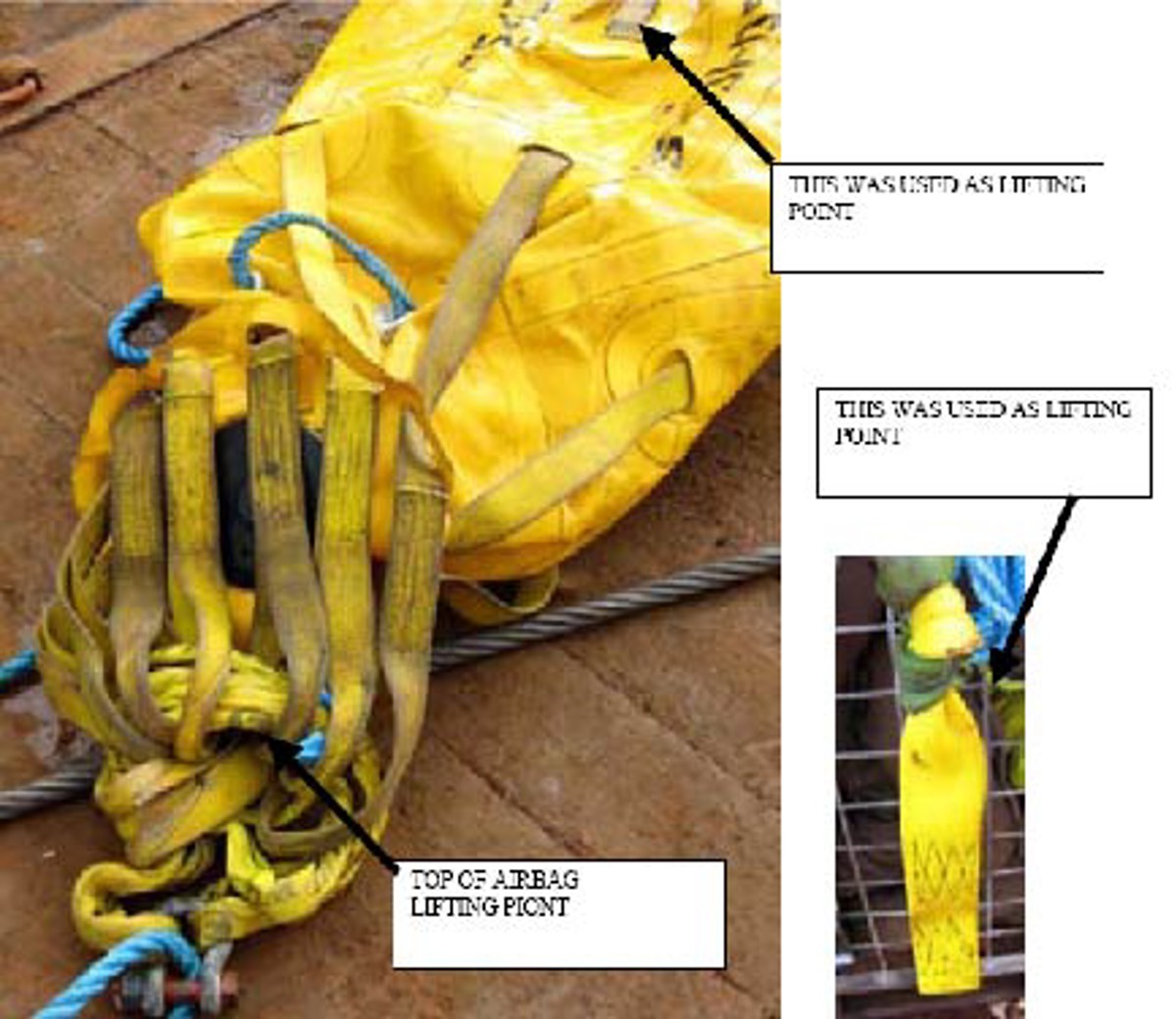

Investigation revealed that the points used for lifting the bags were not appropriate certified lifting points but only user handling points. Subsequent tests demonstrated that these user handling points were insufficiently strong to carry the weight of the lift bag.

The company has made the following suggestions:

- Only use appropriate lifting points, do not use unidentified lifting points.

- Lifting points on lift bags should be clearly marked. Suppliers should be made aware of this requirement.

- Remove or stitch together the man-handling strops, to prevent the possibility of mistakenly using these for lifting the bag during installation and recovery.

Lifting bag similar to that involved in incident

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.