Crewman received 440V electric shock

- Safety Flash

- Published on 8 April 2010

- Generated on 5 February 2026

- IMCA SF 02/10

- 2 minute read

Jump to:

A Member has reported an incident in which an electrician received a 440V electric shock and sustained an electric burn on the left middle finger and an abrasion on the right palm.

What happened?

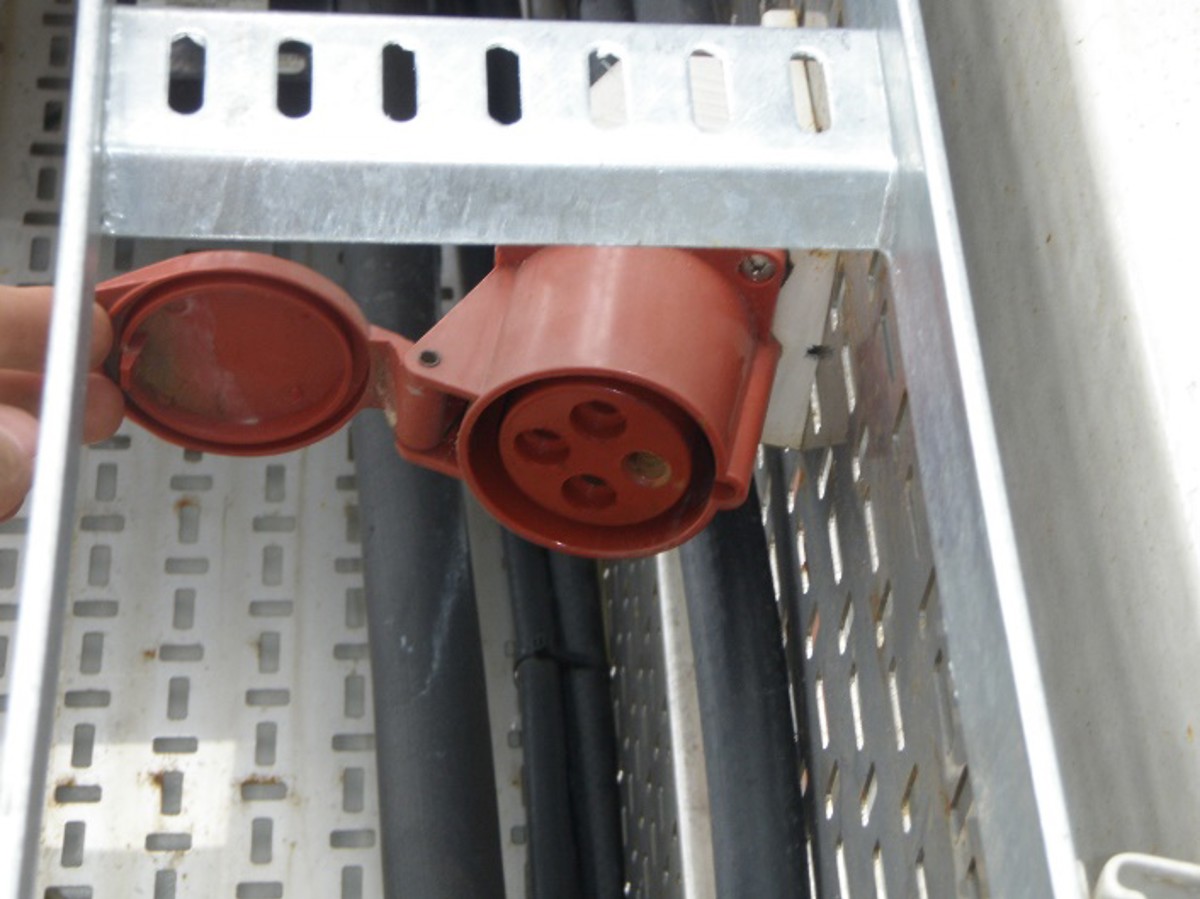

Whilst undergoing refit works at a repair yard, an electrician was checking the electrical systems on the newly installed temporary living quarters (TLQ) when he saw that the power supply cable (4-pin-male plug) was disconnected from the socket/isolator. He attempted to plug in the supply cable and subsequently received a 440V electric shock. He was slightly injured and was attended by medical personnel onboard the vessel and ECG (electrocardiography) was administered. He was admitted to hospital for 24 hours and subsequently placed on light duties.

The company made the following observations:

- The electrical works including commissioning for electrical systems on the TLQs were already completed.

- Following this, the supply lead had been removed from the socket but the supply had not been isolated.

- The electrician was called to investigate why there was no power in the TLQs.

- There were a large number of sub-contractors working on the installation at the time of the incident.

- The 440V power supply was not isolated from the main switchboard prior to connection.

- TLQs were supplied with female sockets which resulted in the extension cable having a live male end.

The company made the following changes:

- The sockets on the three TLQs on board the installation were changed for male sockets such that the live supply wires have safer female plugs.

- The manufacturer of the TLQs was informed of this potentially hazardous arrangement of power supply sockets.

- The importance of rigorous lock-out tag out procedures was reinforced to crew and fleet.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.