Dropped GRP cover during subsea lifting

- Safety Flash

- Published on 22 January 2026

- Generated on 23 January 2026

- IMCA SF 02/26

- 4 minute read

Jump to:

A vessel was lifting and relocating a Pipe Line End Manifold (PLEM) GRP Top Cover when the load became detached and dropped approx. 7m.

What happened?

A vessel was lifting and relocating a Pipe Line End Manifold (PLEM) GRP Top Cover when the load became detached and dropped approx. 7m, landing on the side of the PLEM bottom GRP structure. The fibreglass lifting points failed on the GRP cover, but there was no damage to the PLEM or bottom GRP structure, nor any injuries to personnel.

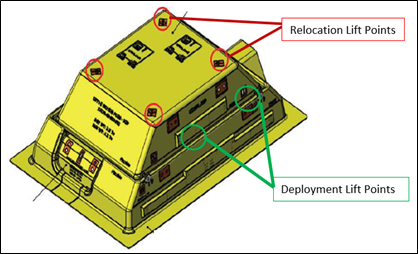

The Top Cover has two different types of lifting points. One set is designed for deployment and consists of pairs of profiled, reinforced holes where round slings are routed. The other set is designed for subsea relocation and consists of bars designed for easy connection to ROV hooks.

Divers attached the crane to a 4-part bridle of the Top Cover via the bar lift points. Divers were instructed to move to a safe distance throughout the relocation operation, and the lift was to be monitored by ROV only. As per the lift plan, the crane operator was instructed to enter ACT (Active Constant Tension) mode and progressively come up on the load. Lift plan used ACT as a control measure in case the top cover snagged during lifting. The crane continued increasing weight until a maximum of approx. 10Te (Expected Weight: 9.9Te) was seen, at which point the GRP top cover completely lifted free of the bottom cover. The GRP cover was lifted 7m above the bottom cover to allow clearance over PLEM structural elements and valves. The Dive Supervisor then instructed the Crane Operator to switch from ACT (Active Constant Tension) to AHC (Active Heave Compensation) for the remainder of the lift.

At this point the divers reported hearing a series of loud cracking noises and the crane operator reported that the crane was no longer reading any load. During this period, the ROV was confirming that their tether was safe for the ongoing lift resulting in losing visibility of the load. Once the ROV had re-established visual contact with the GRP cover it was found to have completely detached from the lift rigging, had flipped over on to its back and come to rest partially on the side of the PLEM bottom GRP structure.

What happened next?

- An ALL STOP was called, all key stakeholders were informed;

- ROV survey of the worksite;

- Management of Change process initiated:

- A new lift plan was created to cover the operations of upending, lifting, and relocating the GRP cover

- The requirement to use “Active Constant Tension” was removed to avoid the need of a crane mode switch

- Future lifts utilised the 'deployment' lift points

- All crane, video, witness statements & physical evidence collated and an investigation initiated.

What were the findings?

- The crane had to be in heave compensated mode to avoid the hydrodynamic loads overloading the cover. However, the direct switch from ACT to AHC was not possible on that specific crane and there was an intermediate stage where the load was required to be in 'normal' mode. This short period was enough to cause an excessive load on the lift rods.

- The calculation package for the lifting rods was erroneous and resulted in an undersized rod/overestimated load capacity - even though the pins were overloaded, they failed at a lower value than should have been expected.

- There could have been better awareness and understanding of the limitations of different crane mode transitions by those planning and executing the lift.

- The lift plan should have either used AHC throughout and used other control measures to mitigate against the initial snag risk, or the weather criteria for the lift have been based on 'normal' mode and the lift plan reflecting the required mode transition phases.

- Good Practice: Keeping divers clear of the lifting operations prevented potential serious injury.

Related Safety Flashes

-

IMCA SF 19/23

3 August 2023

-

-

IMCA SF 18/25

2 October 2025

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.