Fatality during basket transfer

- Safety Flash

- Published on 30 January 2013

- Generated on 6 February 2026

- IMCA SF 03/13

- 3 minute read

Jump to:

A member has reported an incident in which a crew member suffered a fatal fall from a Billy Pugh X-800 series personnel basket during a transfer between an incomplete platform jacket and heavy lift barge.

What happened?

The basket started swinging and the person fell and landed on a walkway of the platform jacket, suffering serious head injuries. He was evacuated to hospital and subsequently died of his injuries.

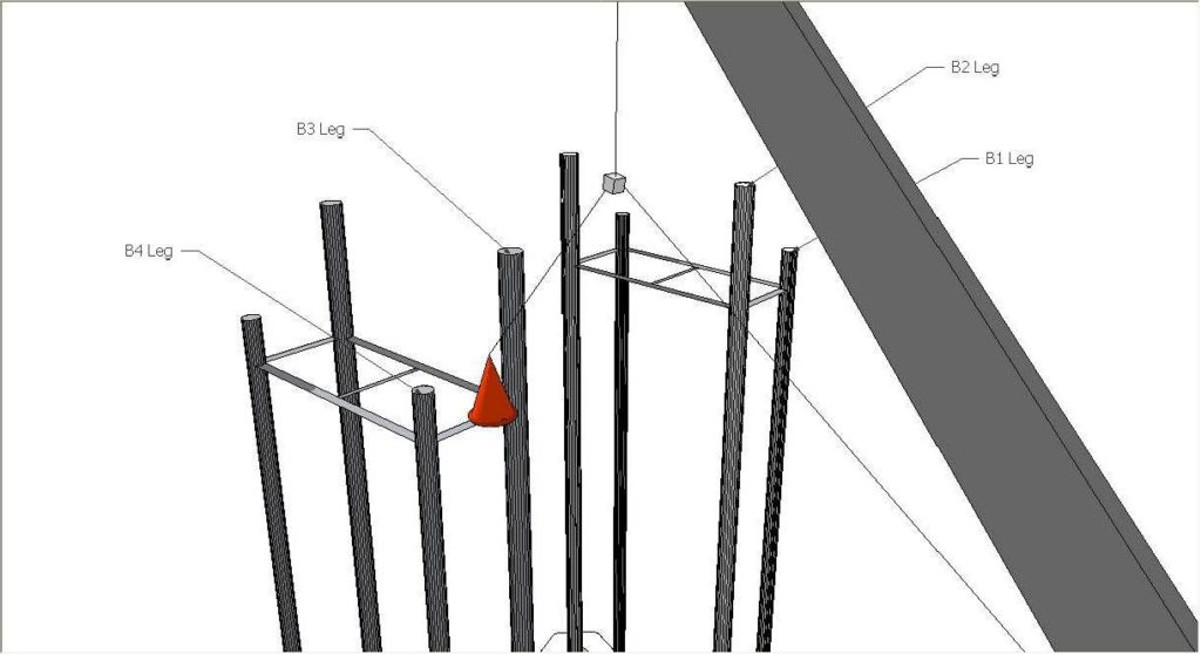

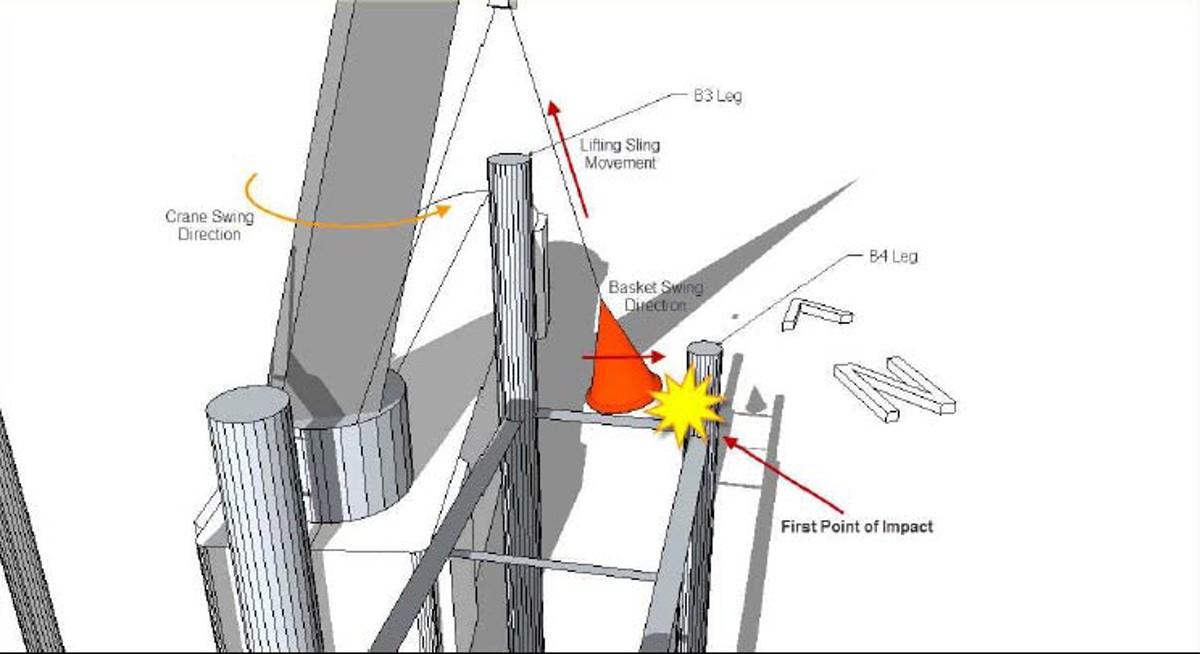

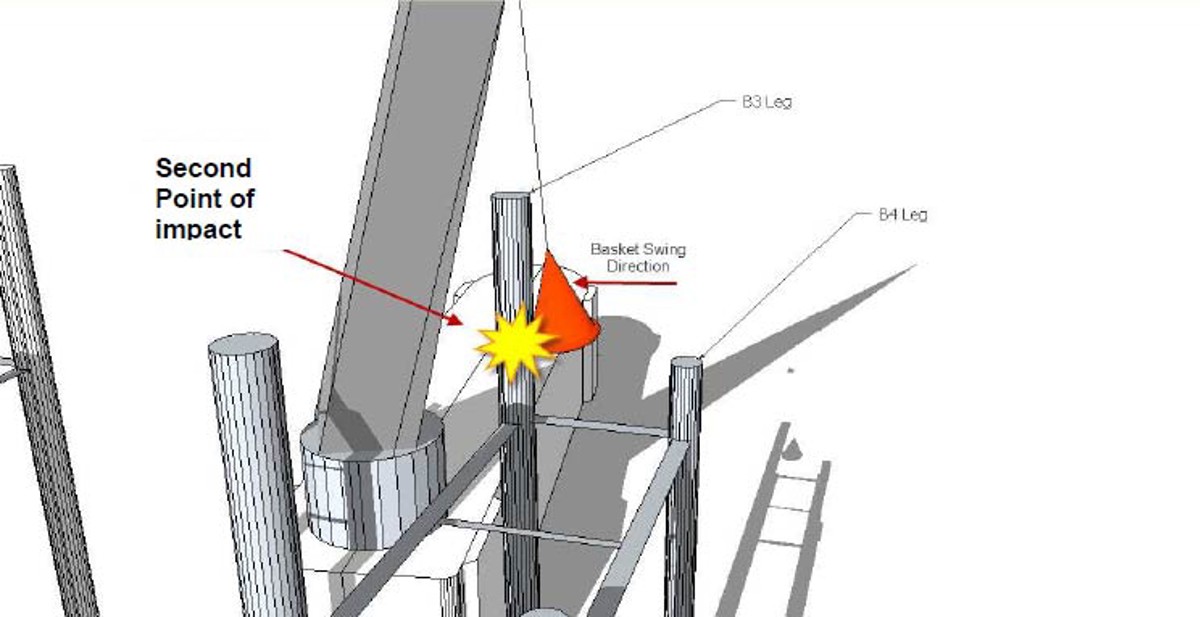

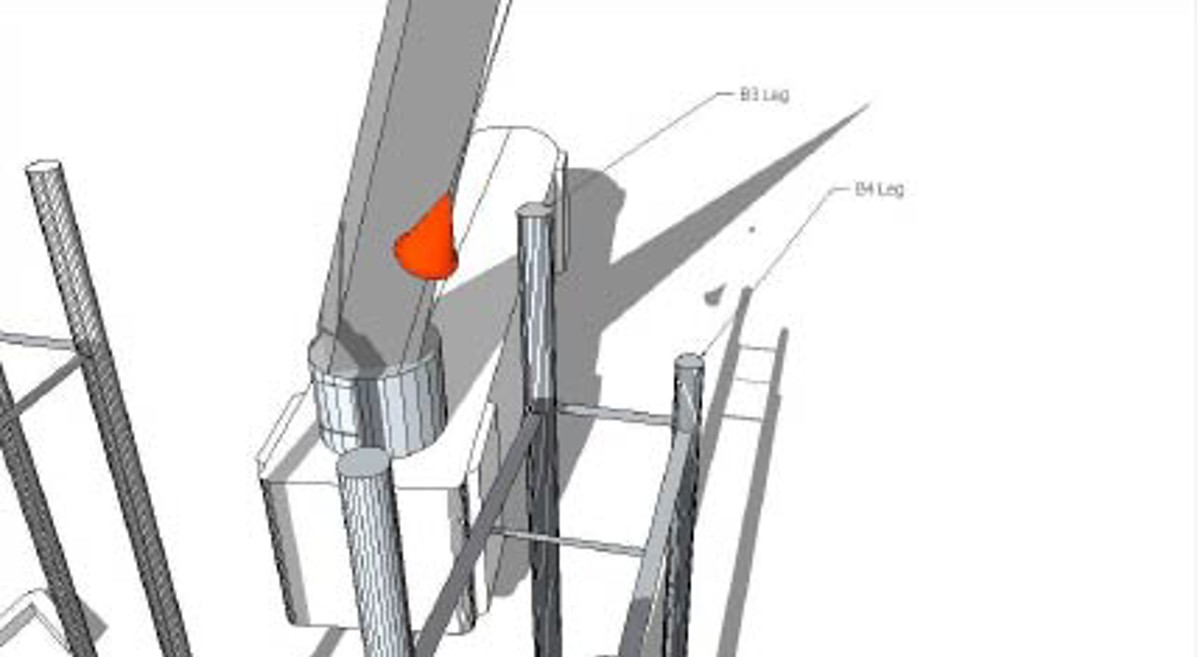

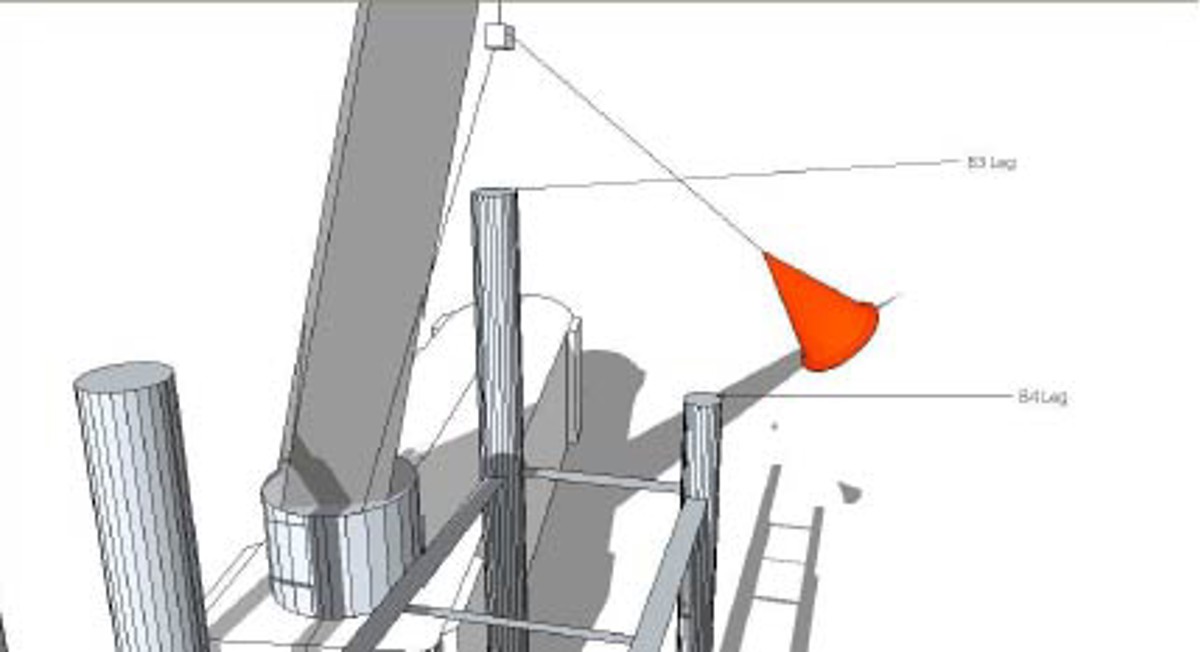

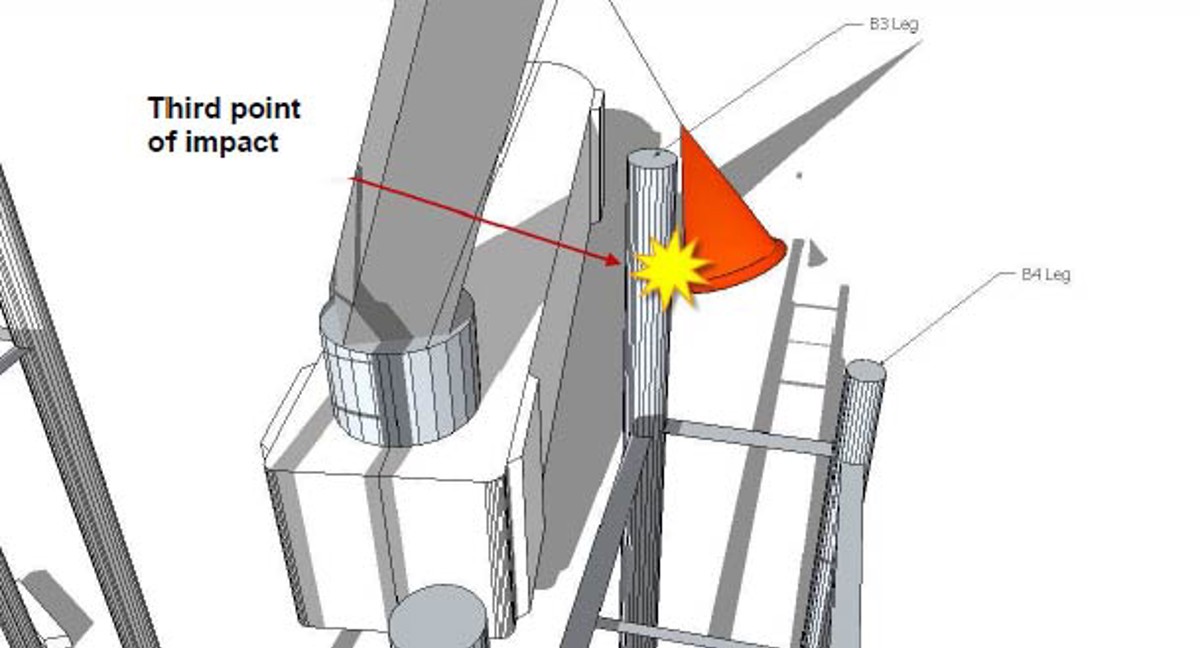

A series of sketches follows which describes the incident in more detail:

Basket landed between B3 and B4 transition piece to pick up two persons

Basket begins to swing when lifted

Basket strikes platform transition

Basket continues to swing with both personnel on board

Basket continues to swing with both personnel on board

Basket continues to swing with both personnel on board

Basket continues to be raised whilst swinging and spinning, at this point one person loses his grip and falls from basket (approx. 8m), landing on walkway between B4 and E4 legs

Investigation

The company’s investigation revealed the following causes:

- There was no provision of an adequate landing platform for the personnel basket.

- The basket landing area being used was on a walkway grating 1.2 m in width and between two transition pieces of the jacket.

- During the lifting operation of the basket the crane barge was rolling and pitching between 1-2 degrees and the boom angle of the crane was at 31 degrees (main crane in use), a combination of factors which allowed the basket to swing when raised.

- The crane operator continued to lift the basket despite it striking the transition pieces of the jacket.

- The two tag lines attached to the basket were not used to stabilise the basket whilst it was being hoisted.

Lessons learnt

Following the incident, it was noted that all offshore personnel transfer methods involve some degree of risk.

- The method of personnel transfer should be taken into account when conducting assessment of risk for the project.

- The transfer method should be identified and mitigating factors agreed with the client prior to the start of operations.

- Mitigating factors should be taken into account, such as environmental limit criteria, provision of adequate landing areas and use of the most appropriate mode of transfer.

Actions

The company and its client took the following actions:

- Review the type of basket currently in use and consider an alternative which can provide impact and fall protection.

- Identify and provide a proper landing platform for personnel basket landing in the initial jacket positioning phase.

- Reinforce standard operating procedure with regards to personnel basket transfer and lifting operations.

- Reinforce the stop work policy. All personnel have the right to refuse to be transferred or conduct a transfer when they consider the situation unsafe to do so.

- Reinforce the safety awareness of personnel basket transfer by conducting more safety discussions on the subject. Personnel working on barges which use personnel basket transfer method have been reminded about the safety issues, to be more vigilant and exercise their right to stop the work if they see the conditions are unsafe to continue.

Members may wish to refer to Guidance on the transfer of personnel to and from offshore vessels and structures.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.