Near miss: pilot ladder – side rope failed

- Safety Flash

- Published on 18 January 2023

- Generated on 6 March 2026

- IMCA SF 03/23

- 2 minute read

Jump to:

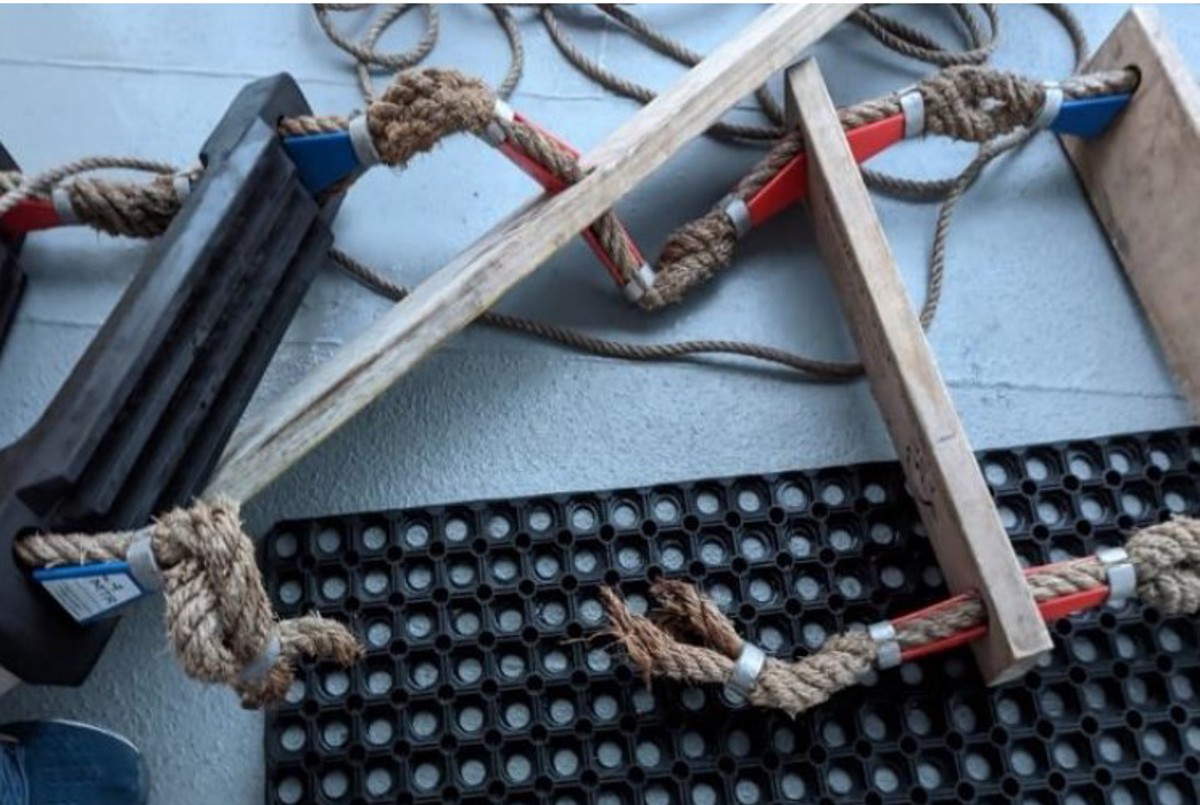

Whilst undertaking pilot boarding operations at night, a side rope on the pilot ladder parted while being weight tested by the pilot.

What happened?

The pilot was not injured; however if the ladder had not been weight tested by the pilot, it could have failed whilst it was being climbed, resulting in a fall from height into the sea.

The pilot boarding operation was aborted and the vessel directed by the authorities to anchor, resulting in significant operational and commercial delays.

What went wrong?

Key findings

- The pilot ladder had not gone through a 30-month strength test because the requirement to do so had not been uploaded into the vessel’s planned maintenance system.

- It was known that the pilot ladder was in poor condition, but it was decided to continue to use the ladder beyond its operational life knowing that the vessel would soon be decommissioned.

- The vessel did not carry a spare / second ladder.

Action taken

- A Pilot ladder is essential safety equipment and should always be serviceable / available for use.

- Safety critical equipment should be inspected before use and any deficiencies found should be reported and rectified.

- The defective pilot ladder was replaced with a new ladder.

- Carry a minimum of two pilot ladders and replace them every two years.

- Ensure vessel planned maintenance systems are up to date and include everything that should be included.

The following documents will be useful:

- SOLAS Regulation 23 on Pilot Transfer Arrangements

- International Chamber of Shipping (ICS) Shipping Industry Guidance on Pilot Transfer Arrangements – Ensuring Compliance with SOLAS

- IMO Resolution A.1045(27) Pilot Transfer Arrangements

Related safety flashes

-

IMCA SF 24/20

14 August 2020

-

-

IMCA SF 02/19

13 February 2019

-

IMCA SF 24/18

30 October 2018

-

-

IMCA SF 17/13

29 November 2013

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.