Single point failure resulting in a dropped object

- Safety Flash

- Published on 18 January 2023

- Generated on 21 February 2026

- IMCA SF 03/23

- 2 minute read

Jump to:

A small part weighing 0.3 kg fell 20 metres from an OMC-160 wind speed and direction sensor installed on a vessel’s main mast.

What happened?

Two wind speed and direction sensors were installed on the vessel’s main mast; they consisted of a wind speed sensor and a wind direction sensor.

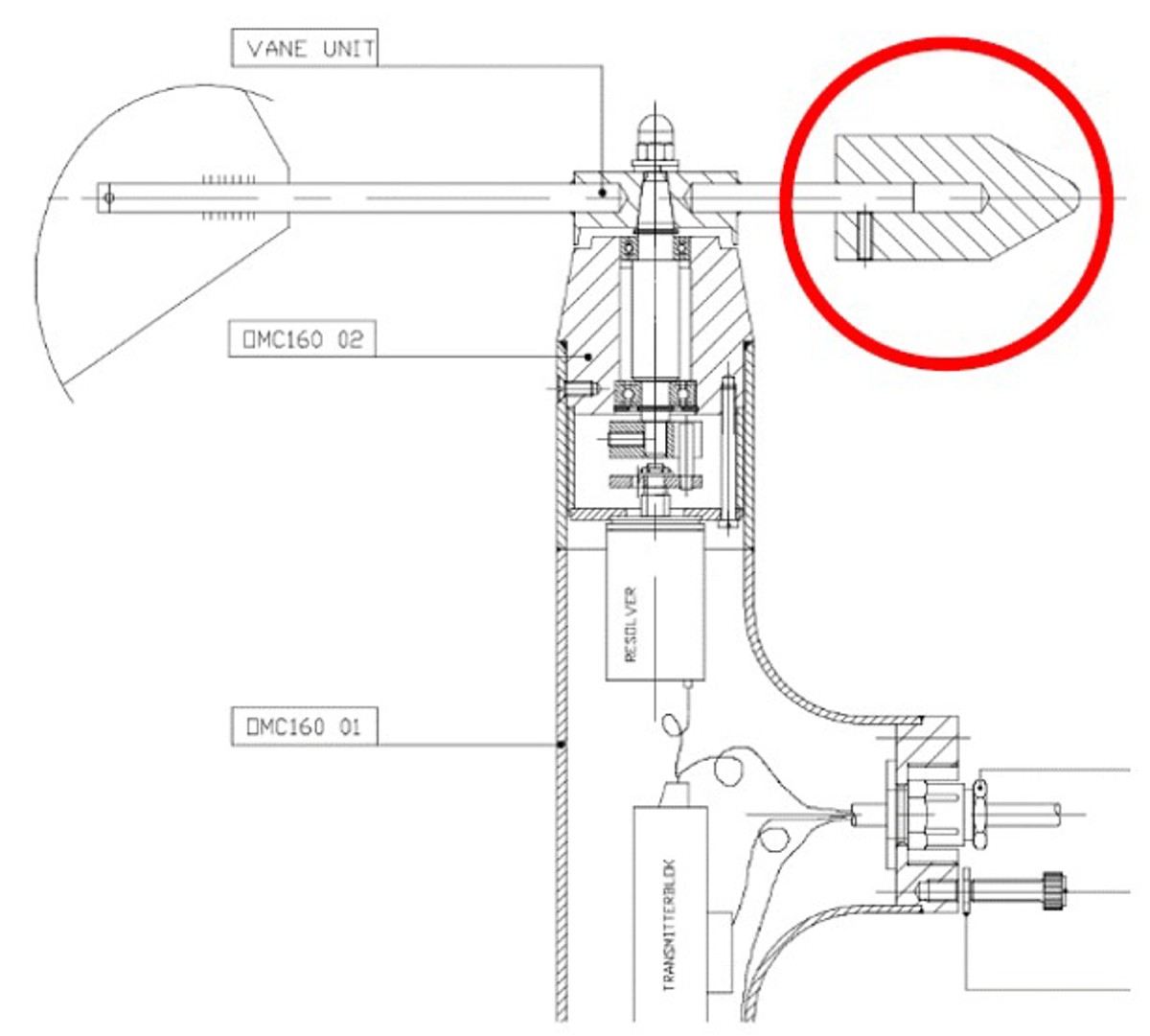

The wind direction sensor was of the wind vane type unit and had a counterweight (length 6 cm / diameter 3 cm; 300 grammes) fixed to it.

This counterweight was only secured to the wind vane by a single grub screw. The grub screw came loose causing the counterweight to fall off.

There were no injuries, nor any damage to the vessel or equipment.

before: single point failure – one grub screw

after: new securing method - two grub screws

What went wrong?

- The counterweight was secured with only one screw, and this single point failure was not identified during the previous DROPS surveys.

- The OMC-series wind sensors are designed for minimal maintenance and as such were not part of the vessel’s planned maintenance system.

- The original grub screw worked loose because of vessel vibration.

Preventative action

- The crew secured the counterweight by drilling one more hole on the opposite side of the existing one, and thus used two new screws to secure it. In addition, Loctite was applied to secure these screws.

- After checking for similar situations on the main mast, the same modification was done to the counterweight on the second direction sensor.

- Check if there is anything similar in your work area that could fall from height following a single point failure, or, is not included in the vessel planned maintenance system – check all instruments on masts.

- Check fixings at height very thoroughly. Particularly worthwhile and important when access is difficult.

Related safety flashes

-

IMCA SF 14/16

17 May 2016

-

IMCA SF 10/15

16 July 2015

-

IMCA SF 04/10

14 July 2010

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.