Near-miss: Pilot ladder failure

- Safety Flash

- Published on 5 February 2016

- Generated on 6 March 2026

- IMCA SF 04/16

- 2 minute read

Jump to:

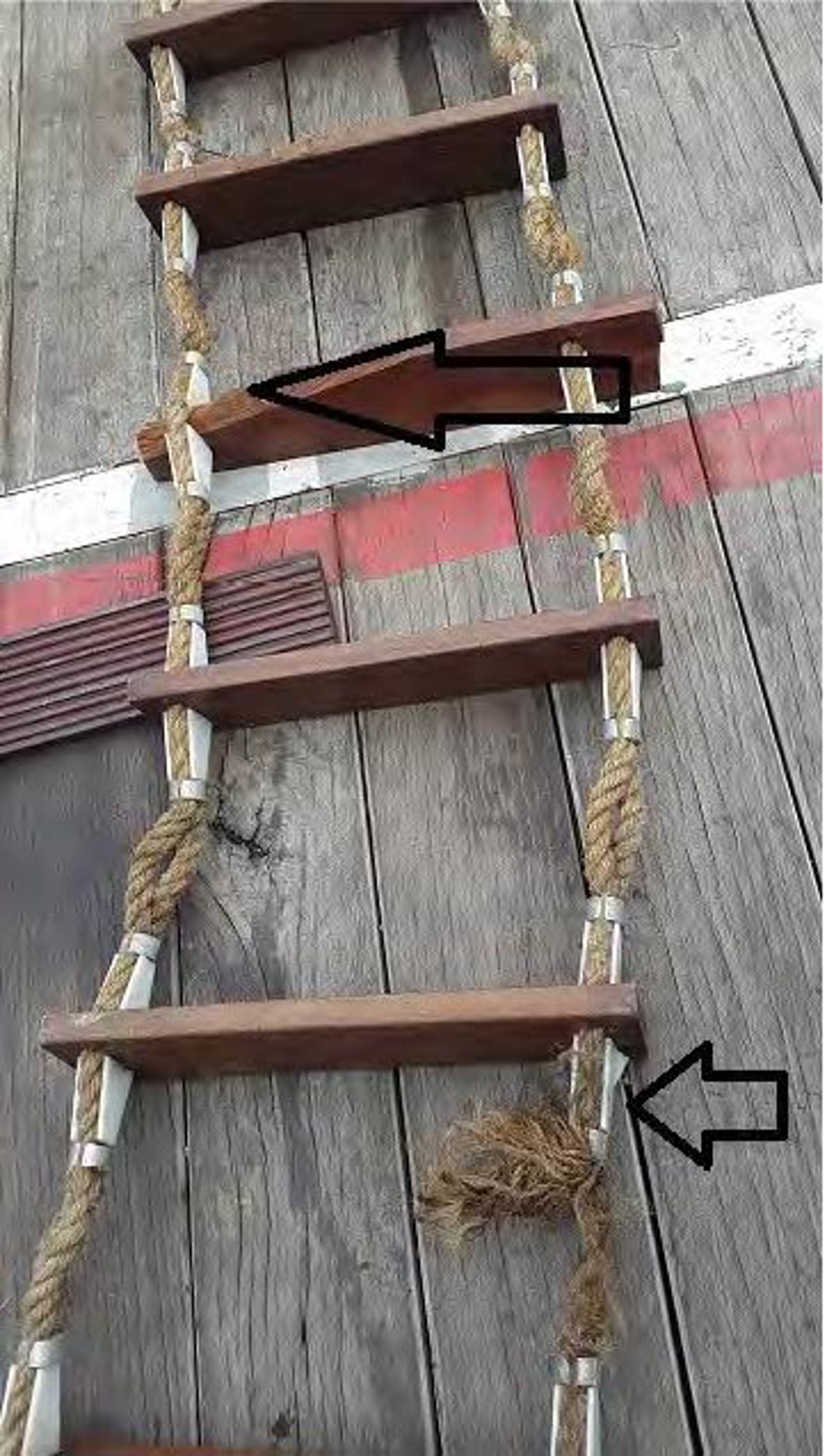

A member has reported an incident during an embarkation offshore, in which a rope on a pilot ladder snapped. The person boarding the vessel managed to hold onto the hand line which was rigged alongside the pilot ladder, thus preventing himself from falling overboard.

Our member’s investigation revealed that:

The pilot ladder had been checked as part of the monthly safety checks and had been recorded as ‘Out of Order’ – but had not been removed from use and quarantined.

A requisition had been raised for a replacement pilot ladder, but the new ladder was still awaiting delivery.

No crew member exercised the STOP WORK POLICY, despite being aware of the ladder being damaged.

The following safety barriers were observed to have failed:

- Operational procedures - existing guidance was not sufficient to deal with this case.

- Maintenance procedures.

Our member took the following actions:

- The pilot ladder was immediately quarantined.

- All other vessels were instructed to inspect their pilot ladders for serviceability.

- Changed company procedures on the quarantine of (faulty or damaged) tools and equipment.

Any tools or equipment found to be faulty, damaged or defective should be taken out of use and tagged/quarantined. This near miss incident need not have happened had someone on the crew taken the initiative to stop the job. Our member’s STOP WORK POLICY should have been exercised, either during the monthly safety checks of the ladder or before the personnel transfer.

Related Safety Flashes

-

IMCA SF 17/13

29 November 2013

-

IMCA SF 17/13

29 November 2013

-

IMCA SF 11/11

27 October 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.