Potential dropped objects left on loaded cargo

- Safety Flash

- Published on 20 February 2018

- Generated on 23 February 2026

- IMCA SF 04/18

- 1 minute read

Jump to:

A member reports numerous instances of potential dropped objects being found on containers and equipment being loaded from port and offshore facilities.

What happened?

What went wrong? What were the causes?

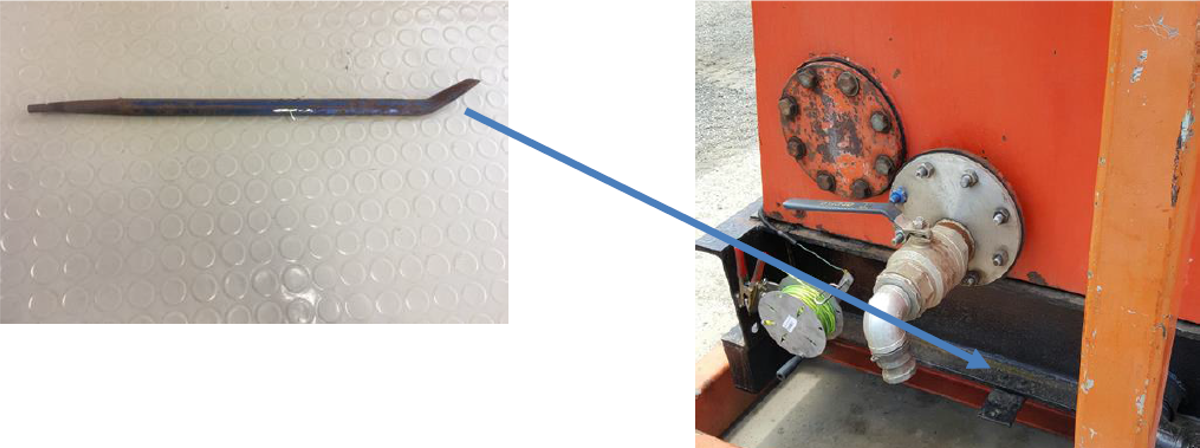

Items of significant weight, such as a bag of fittings weighing 15kg, loose rocks, scissors, crow bars, large pieces of wood and loose lumps of steel affected by corrosion, have all been found when loading cargo.

The primary causes were poor housekeeping and failing to conduct inspections of loads before, during and after lifting operations.

What lessons were learnt?

- Containers and equipment being loaded and unloaded have been prepared by a third party. Great care and caution should be exercised when accepting these loads.

- ALL parties in the supply chain have a responsibility to inspect loads before first lift, during transit and when unloading.

- Ensure good housekeeping on and around all containers/equipment;

- Never stand under a load.

- Establish exclusion zones during lifts.

Dropped objects from cargo are a significant source of incidents reported to IMCA and to other industry organisations including Step Change and the Marine Safety Forum (MSF), and remain a grave concern.

Related Safety Flashes

-

IMCA SF 26/17

20 October 2017

-

-

IMCA SF 19/14

18 December 2014

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.