Lifting equipment failure: Objects dropped into moonpool

- Safety Flash

- Published on 2 April 2015

- Generated on 7 March 2026

- IMCA SF 05/15

- 2 minute read

Jump to:

A Member has reported an incident in which a chain hoist failed causing a 700kg load to fall into the moonpool.

What happened?

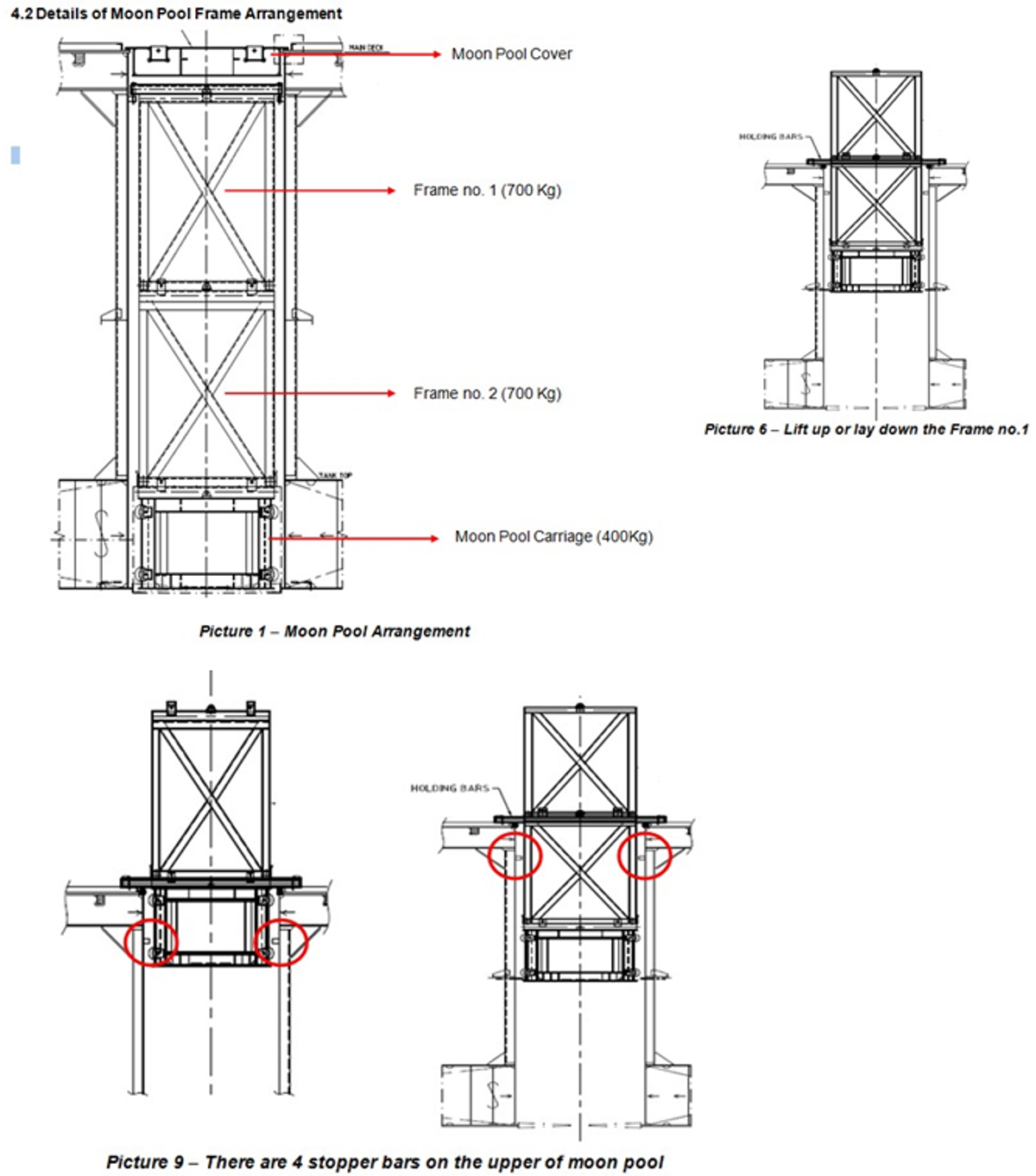

The incident occurred when crew were moving moonpool carriages and frames into position during mobilisation of multibeam echosounder equipment through the moonpool. The moonpool carriage was successfully positioned.

As the crew lowered the second moonpool frame into position, the chain on the hoist crane suddenly parted and the frame and carriage fell into the moonpool damaging one of the stopper bars on the wall of the moonpool before being stopped by the other stopper bars.

There were no injuries. There was some damage to the stopper bars and brackets.

multibeam carriage before deployment to moonpool

frame before deployment to moonpool, attached to multibeam carriage underneath

damage to engine room wall (other side of moonpool) following stopper bar broken

damage to side of moonpool after stopper bar was broken

details of moonpool frames and stopper bars

Findings

Our member’s investigation noted the following:

- Before starting the job, all personnel involved took part in a toolbox meeting and job safety analysis (JSA). A permit to work had been granted.

- The first lift, using the crane in remote control mode, was successful.

- The hoist crane had a safe working load (SWL) of 5 tons.

- The immediate cause of the incident was found to be that during the lifting of the frame, it was obstructed by one of the bracket stoppers.

- The underlying cause was stress and subsequent failure of the chain of the hoisting crane.

- The root causes were:

- Lack of specific procedure regarding lifting a moonpool frame.

- Lack of awareness from crew who handled lifting moonpool frames to ensure smooth process during lifting.

Actions

The following corrective actions were taken:

- Update annual load test to include dye penetration test to check for unseen cracks on hoist chain.

- Update procedures and JSA for moonpool activity.

- Replace hoist and chain and repair stopper bar inside moonpool.

- Defective chain sent to certified third party testing for examination of strains caused by overstressing.

Members may wish to refer to the following similar incidents (key words: chain, failed):

- Offshore tank container rigging failure

- Near-miss: Safe use of chains in rigging

Related safety flashes

-

IMCA SF 01/15

16 January 2015

-

IMCA SF 12/11

1 November 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.