Dropped object near miss – Crane boom bumper stop falls off

- Safety Flash

- Published on 13 February 2020

- Generated on 14 July 2025

- IMCA SF 05/20

- 3 minute read

Jump to:

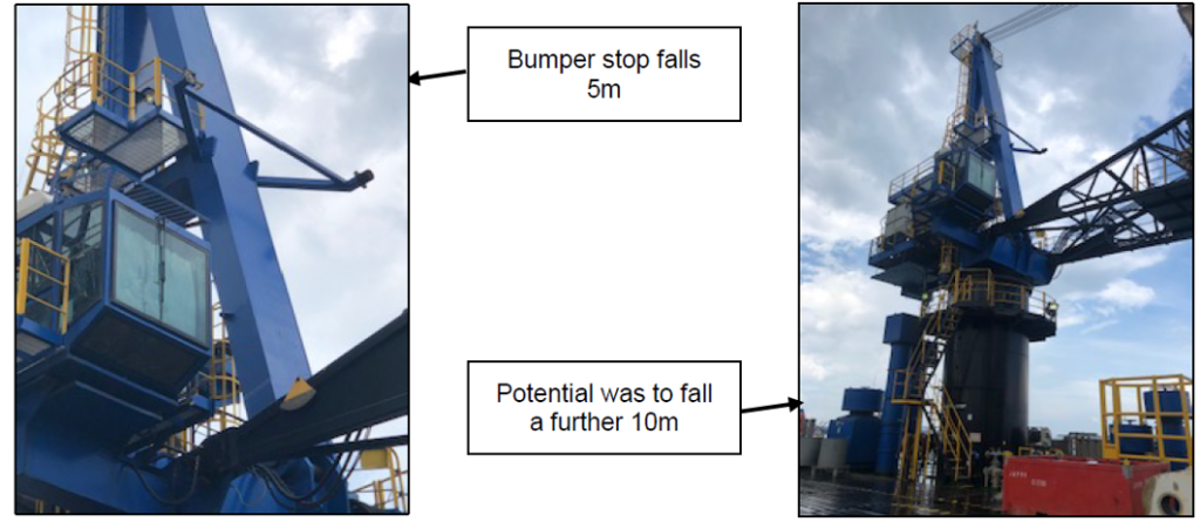

This was a high potential near miss dropped object incident in which a crane boom bumper stop fell onto the crane cab. No personnel were injured; however, there was potential for serious or fatal injury.

What happened?

The incident occurred during preparation for vessel reactivation following a period in warm stack; a crane mechanic spotted a part of one of the vessel cranes had fallen off and was missing.

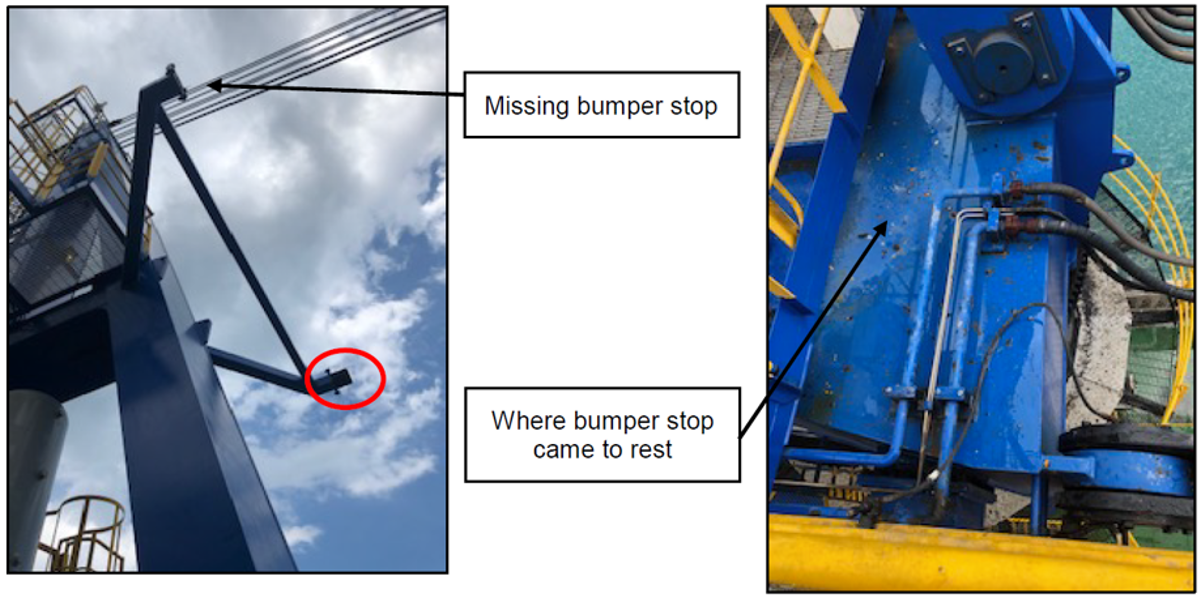

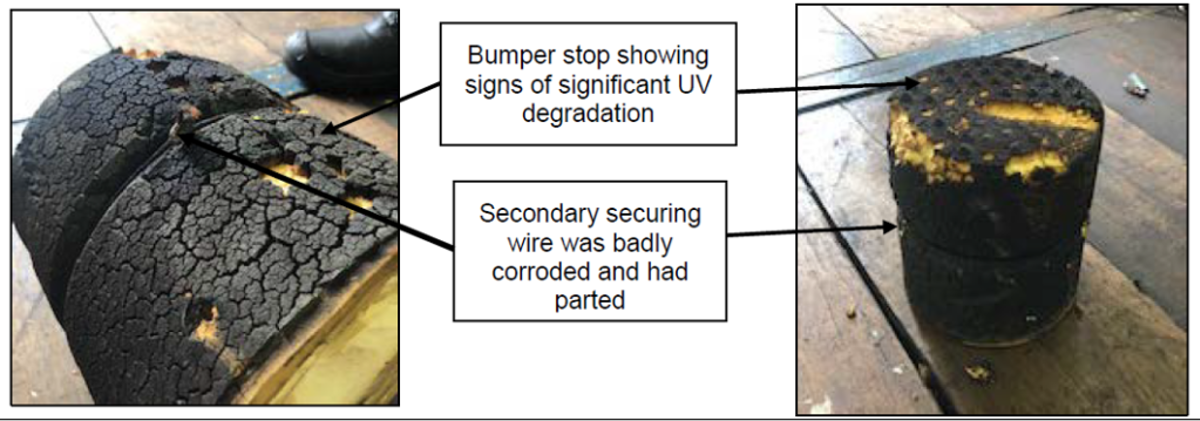

The crane mechanic stopped his inspection and proceeded up the crane to investigate further. The bumper stop was observed laying on the crane cab level outside of the handrails. The bumper stop is made of vulcanised rubber that is bonded to a steel securing plate and fitted to the crane A frame with steel bolts. A steel wire secondary securing lanyard was fitted around the circumference of the vulcanised rubber and tied back to the A frame. The vulcanised rubber had detached from the steel securing plate which remained attached to the A frame; however, the secondary securing wire had corroded and parted allowing the bumper stop to fall.

During the warm stack period, dropped object inspections had routinely been performed on all three vessel cranes, with the most recent one being carried out a few days before this near miss incident.

What lessons were learned?

- The vulcanised rubber section of the bumper stops was vulnerable to UV light damage.

- Secondary retention wires should be manufactured from a corrosion resistant material.

- The location and lack of accessibility to the bumper stops prevented regular and sufficient physical inspection:

- The condition of the bumper stops and the secondary retention device could not be fully assessed without scaffolding, rope access or alternative means.

- The secondary retention wire was not clearly visible from the closest point of inspection 2m away. Degradation of the wire could not be seen.

- The vulcanised rubber section of the bumper stop had deteriorated to an unstable condition and detached from the securing plate.

- There is potential for similar incidents to happen on other vessels, in areas where access to potential dropped objects is difficult.

What actions were taken?

- Continue existing dropped object inspections, and review existing dropped object checklists and/or work orders when next used and update if required.

- Identify equipment and structures that cannot be easily accessed for inspection and present a risk of dropped objects and determine the best means of safe access and frequency of inspection.

- Ensure exposed potential dropped objects are suitably protected from corrosion and ensure retention devices are of suitable strength and made from corrosion resistant material.

- Investigate the use of an alternative bumper stop material that does not degrade in sunlight and consider other components that are vulnerable to UV damage that could result in an incident.

- Consider if inspection or replacement frequency needs to be increased.

Related Safety Flashes

-

IMCA SF 04/18

20 February 2018

-

-

IMCA SF 21/15

7 December 2015

-

IMCA SF 01/12

25 January 2012

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.