High potential near miss dropped object

- Safety Flash

- Published on 13 February 2020

- Generated on 6 March 2026

- IMCA SF 05/20

- 2 minute read

Jump to:

What happened?

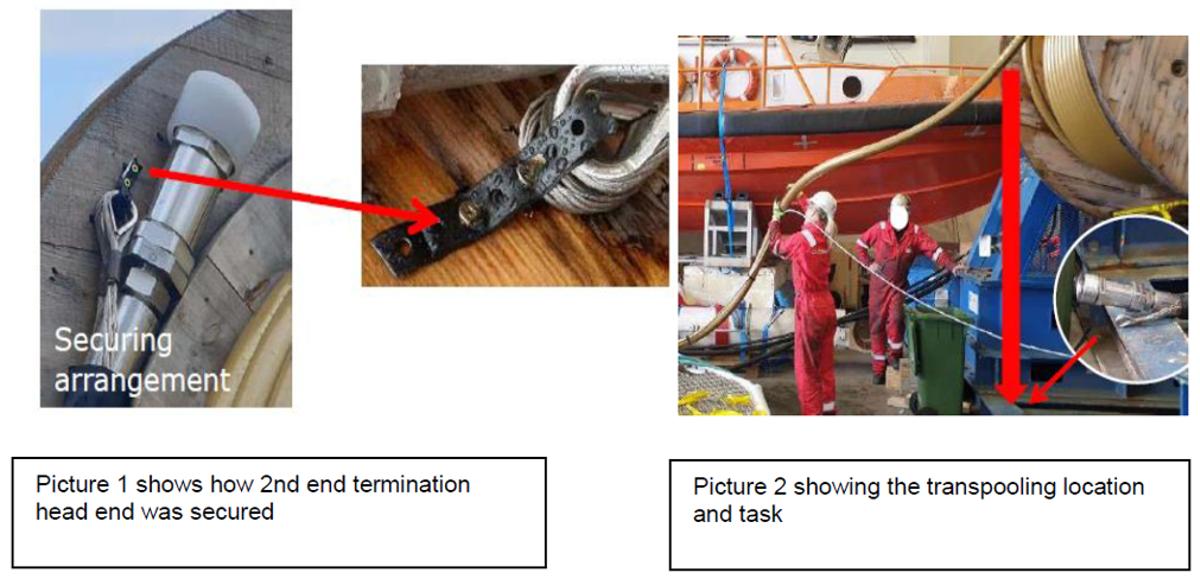

During trans-spooling of 1½” hydraulic jumper from a wooden reel to a subsea carousel, the second end termination head of the hydraulic jumper pipe released from the reel and fell to the floor.

The end termination head, weighing 11 kg, fell from approximately 3 metres down to the floor. It released during spooling of the first two of several layers.

The securing arrangement consisted of a rubber covered metal band that was fastened to the wooden reel with 2 wood screws.

Five people were working nearby and were in the line of fire; the end termination head missed them and there were no injuries.

Our member noted that a similar incident happened in 2017.

What went wrong?

- This specific risk was highlighted in the task plan; however, the task plan was not properly followed on site before conducting the operation.

- The hazards of potential dropped objects were not properly addressed to personnel involved in the pre-job toolbox talk (TBT) and task risk assessment.

- Some personnel involved in the work were not trained in this type of work.

- The distance between the reel and the carousel was too short to allow for the people operating the reel, to attach the wire to the jumper and keep a safe distance from the reel when rotating.

- The securing arrangement for the heads, in this case wooden screws, was inadequate. Additionally, a second barrier was not considered necessary.

What actions were taken?

- Termination heads on reels should be highlighted as potential dropped objects in the task risk assessment (TRA). A second barrier should be added before spooling if proper engineered solutions are not in place.

- Working closely to a rotating reel should be considered a high risk which should be properly mitigated.

- All personnel should be trained for the task they are performing. If there are uncertainties regarding their competence, a competence assessment should be conducted beforehand.

Related Safety Flashes

-

IMCA SF 17/14

31 October 2014

-

IMCA SF 01/07

16 February 2007

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.