Hand injury during retrieval of personal protective equipment (PPE) stored inside a compressor unit

- Safety Flash

- Published on 13 May 2014

- Generated on 5 March 2026

- IMCA SF 07/14

- 2 minute read

Jump to:

An incident has come to IMCA’s attention in which a crewman suffered a hand injury caused by a slamming door on a compressor unit.

What happened?

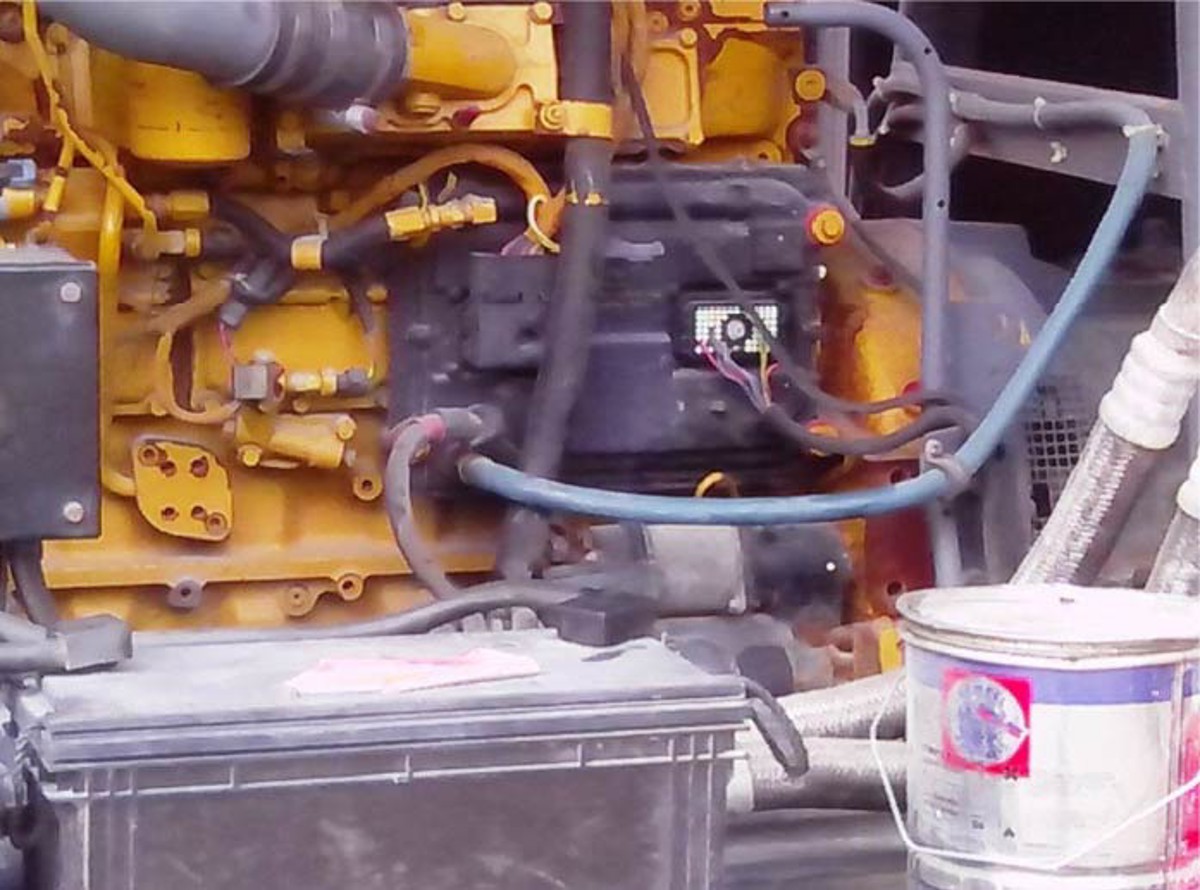

The incident occurred when a contractor worker took off his PPE and kept it inside the compressor whilst visiting the lavatory. When he returned and retrieved his PPE from the inside of the compressor unit, a part of the door slammed due to high wind and caught his hand, resulting in an injury to his index finger. The injured person was rushed to hospital where he was received two stitches.

The investigation revealed the following:

- Using equipment enclosures as temporary storage can potentially lead to harm of people and damage to equipment.

- The worker placed his PPE inside the compressor unit. The inside of the compressor unit was used by the crew habitually as a storage area for PPE.

- There were other flammable materials seen stored inside the compressor unit, which could potentially lead to major fire and explosion.

- The incident was not reported in a timely way.

- There was no evidence of new risk assessment being conducted prior to recommencing of the work, and PPE was seen being stored inside the compressor unit the following day – the lessons were not learnt by the crew.

The following actions were taken:

- Ensure all incidents are reported immediately.

- Ensure no materials are stored inside any operational machinery.

- Ensure PPEs/other materials are stored in designated area only.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.