Rope on propeller causing partial loss of propulsion

- Safety Flash

- Published on 11 April 2018

- Generated on 7 February 2026

- IMCA SF 08/18

- 2 minute read

Jump to:

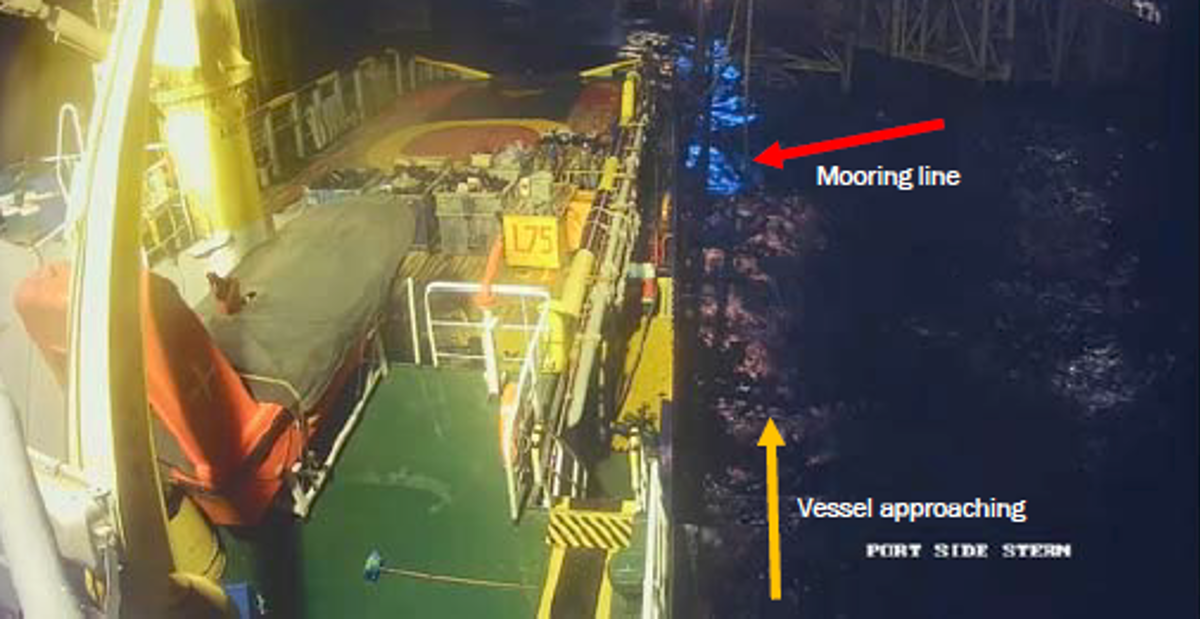

A platform supply vessel (PSV) started mooring operations whilst stern to a platform, without anchoring, in order to conduct a snatch lift.

What happened?

The platform crane operator started to lower a mooring rope of 20cm diameter to the port side of the vessel’s stern quarter bollard area. The deck crew then fixed the end of the mooring rope to the bollard.

At this time, part of mooring rope was lowered to the water. There was a miscommunication between the crane operator and the deck crew, and as a result the rope was fouled on the port side propeller resulting in a subsequent port side engine shut down and partial loss of vessel propulsion.

What went wrong? What were the causes?

- There was a lack of proper planning and risk assessment during the mooring operation.

- There was inadequate communication between the platform crane operator and the mooring crew on deck, which resulted in the mooring line being dropped in the water.

- The deck crew did not notify the bridge in a timely manner when the rope was lowered into the water, and thus the propeller was fouled by the rope.

What actions were taken? What lessons were learned?

- There needs to be adequate means of communication between crane operator, deck mooring team and bridge officer on watch (OOW).

- Proper attention should be paid to the job in hand during mooring operations to ensure a timely reaction to any unforeseen events.

- More detailed risk assessment required for this task where the vessel takes a mooring rope from a platform or rig.

- Stop work authority should be exercised when in doubt.

Members may wish to refer to:

Related Safety Flashes

-

IMCA SF 17/16

30 June 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.