Main bell wire rope damaged

- Safety Flash

- Published on 16 April 2024

- Generated on 4 July 2025

- IMCA SF 08/24

- 3 minute read

Jump to:

A main bell wire was damaged by the proximity switch bracket being picked up by a single broken strand on the main bell wire rope.

What happened?

At the end of a saturation dive, a main bell wire was damaged by the proximity switch bracket (chandelier) being picked up by a single broken strand on the main bell wire rope. The incident occurred during a bell recovery procedure performed by the winch operator. The Moonpool operator stopped the winch operator from further recovery of the bell after noticing that the proximity switch bracket (chandelier) was in the bell launch and recovery sheave. Dive technicians freed up the chandelier from the sheave, and the bell was safely recovered.

The main bell wire rope was three years old, had been visually inspected, and destruction tested with a positive result of 8:1 factory and above the maximum allowable 10% reduction of MBL as per IMCA D018, two weeks before the incident.

What went right?

- When the problem was spotted during bell recovery procedure an “All Stop” was called by one of the moonpool operators and all personnel involved supported it.

- There was a focused and swift reaction from operators to remove the chandelier from bell wire rope sheave. This helped to save time during the bell recovery procedure, this was paramount to a safe bell lock on.

What went wrong?

A single outer wire rope strand, broken from the bell main wire, lifted the chandelier with the proximity switch into the bell main wire rope sheave.

What was the cause?

Our member noted the following:

- Root cause of the incident: Failure of design. The chandelier was a tight fit which allowed movement when the broken wire passed through. The bell main wire ran through a narrow space within the chandelier allowing a single broken outer strand to be caught up.

- Direct cause of the incident: Equipment damaged. A single outer strand broken from the bell main wire was enough to lift the chandelier with the proximity switch into the bell main wire rope sheave.

Actions

- The proximity sensors and chandelier were relocated attaching it to a solid suitable point on the static side of clump weight wire. This eliminated the risk of reoccurrence. See image on right above.

- After cut back of damaged length of bell wire, Classification Society witnessed load test being performed.

- A dive trial was conducted with an empty bell to working depth to double check suitability and length of bell main wire rope.

Related Safety Flashes

-

IMCA SF 18/17

25 July 2017

-

-

IMCA SF 15/17

15 June 2017

-

-

IMCA SF 08/08

24 April 2008

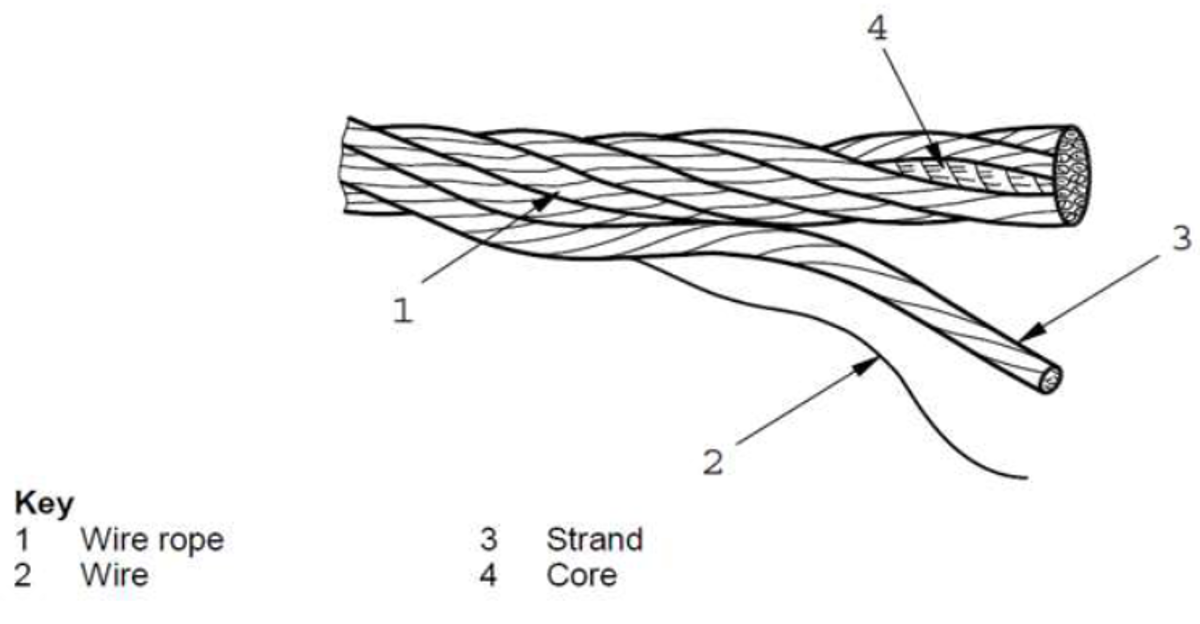

IMCA notes: this flash has been amended to reflect correct terminology with respect to the components of a wire rope: see diagram below. However, for purely practical reasons relating to internet links, the links to previous safety flash incidents relating to wire rope incidents, have not been amended.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.