Fatal accident with lifting appliance

- Safety Flash

- Published on 7 July 2006

- Generated on 5 March 2026

- IMCA SF 09/06

- 1 minute read

Jump to:

IMCA has received a reports on a fatal incident during a lifting operation.

What happened?

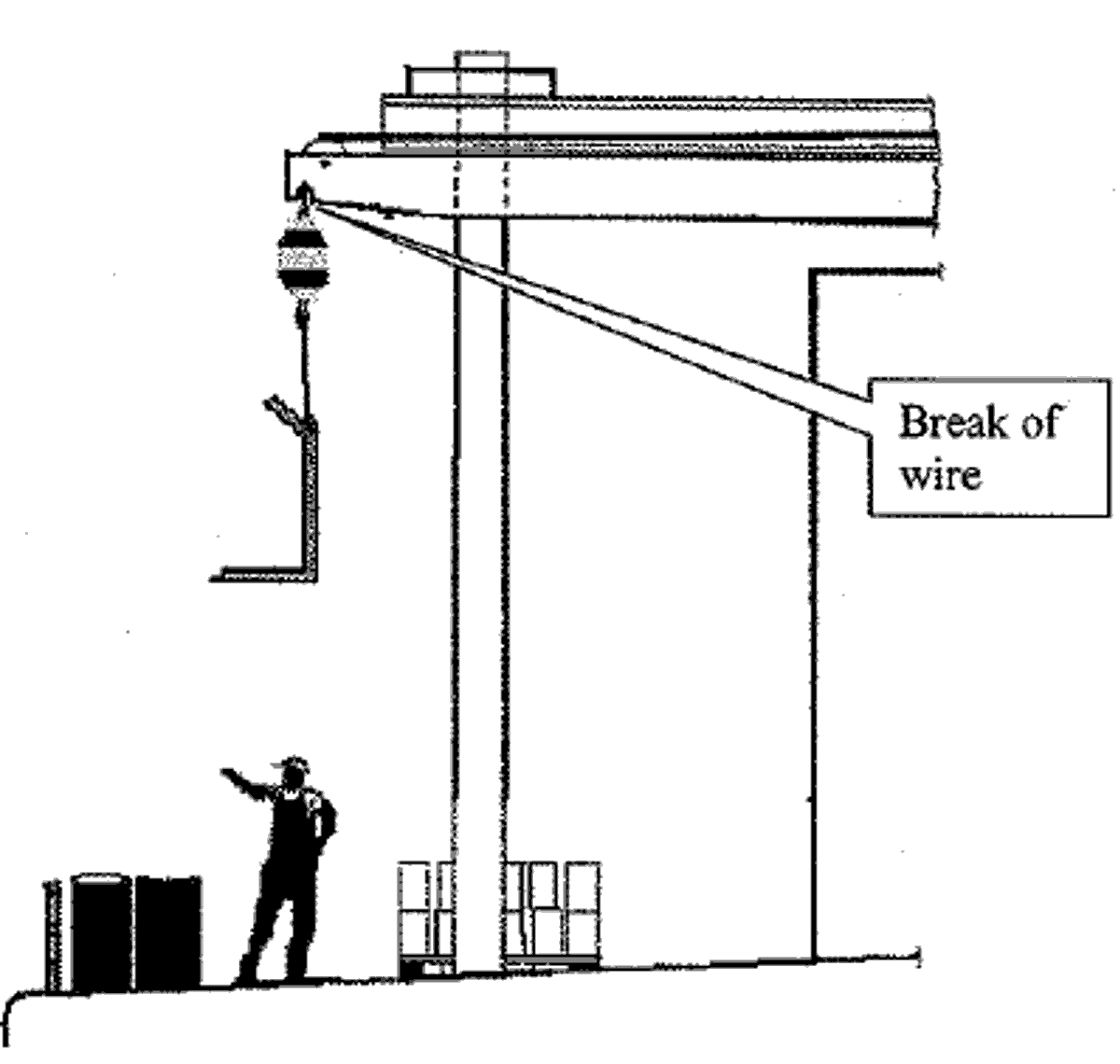

A provisions crane was loading pallets onto a vessel using a pallet fork. After landing a pallet on the deck, the pallet fork was pulled clear and the crane operator moved the crane outward to pick up the next load. During this operation, the crane winch wire snapped. The pallet fork fell onto the deck, landing on a member of the crew, who subsequently died of his injuries.

Sketch of lifting equipment

The company noted the following causes to the incident:

- a malfunctioning or missing upper limit switch’.

- the wire end at the hook side was terminated by means of three incorrectly-applied U-bolt clamps instead of a ferrule and swage (see figures overleaf).

The following lessons were drawn from the incident:

- Limit switches are important safety equipment that should be tested regularly to confirm their proper operation

- Winch wire end terminations should be correctly performed.

- Cranes should be inspected before lifting operations, using an approved check-list.

- Procedures should be established to ensure personnel are properly informed of the hazards involved in crane operations, and do not stand underneath loads.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.