Abrasion of metal casing

- Safety Flash

- Published on 21 May 2008

- Generated on 3 March 2026

- IMCA SF 09/08

- 2 minute read

Jump to:

A Member has reported a case of serious abrasion on the metal casing of the flame arrester on an oxygen hose.

What happened?

This was discovered during ‘routine’ replacement of the securing Jubilee clips on the oxygen hose flame arresters.

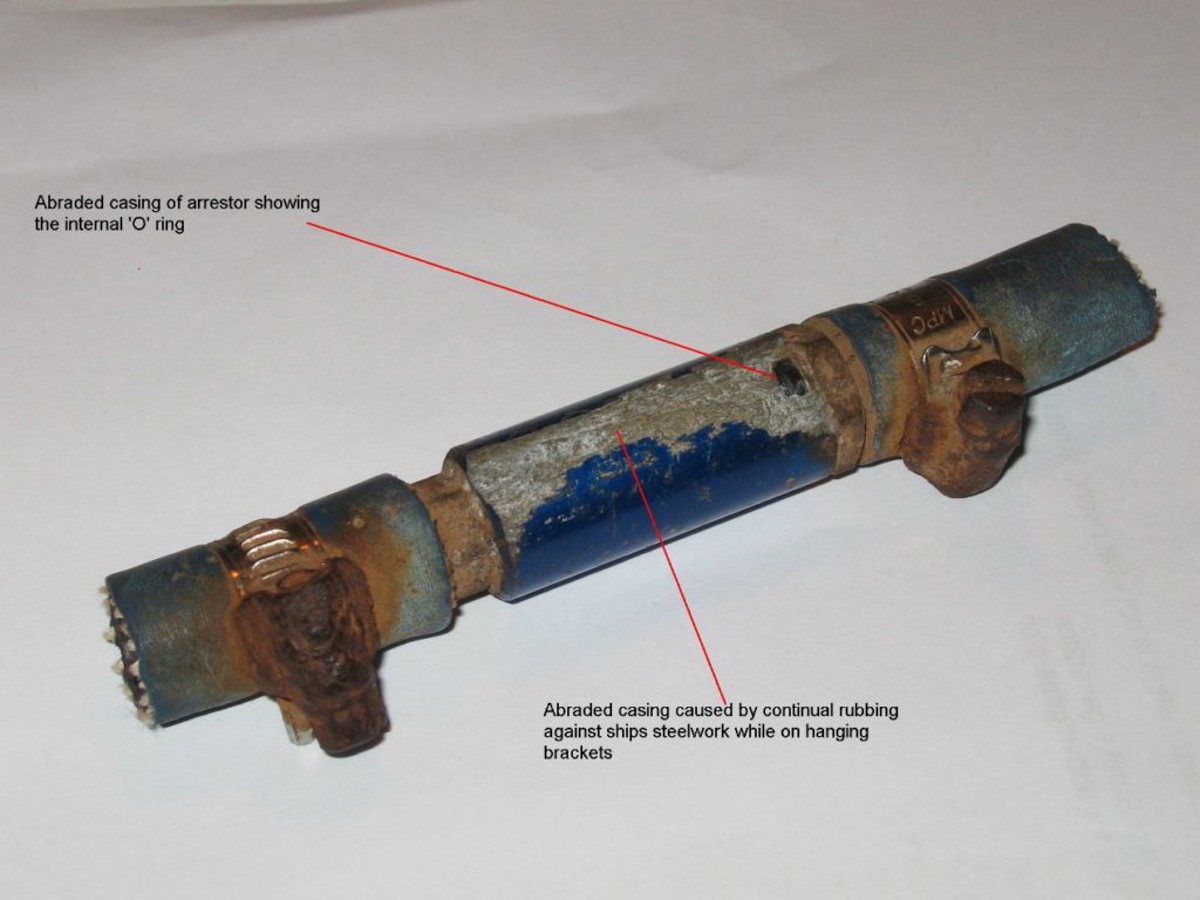

Where the hose had been left coiled on its storage brackets and had been able to swing freely back and forth with the movement of the vessel, it was noticed that this had resulted in the abrasion of the underside of the metal casing of the flame arrester. The resulting wear on the metal was sufficient to reveal the O-ring inside the arrester, as can be seen in the photograph.

This rendered the arrester useless, and it is evident from the photograph that oxygen would now be able to leak freely past this area and into the atmosphere, thereby enriching it and making it more readily combustible should fire or a cause of ignition occur.

It is not uncommon for lengths of oxy/acetylene hose to be stored in ‘out of the way’ places, ready to be uncoiled and used on an occasional basis and, as a consequence of this, defects may only be noticed when the equipment is eventually needed.

Jubilee clips may be considered inappropriate for such hose connections as they can easily corrode and, due to their small size, do not provide an adequate sealing effect. Members are recommended to check all such hoses and arresters for wear and damage: this equipment is sometimes needed in a hurry and should always be in a serviceable condition.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.