Lifeboat davit failure

- Safety Flash

- Published on 10 July 2009

- Generated on 12 February 2026

- IMCA SF 10/09

- 2 minute read

Jump to:

Following a refit, sea trials were being conducted on a Member’s vessel in preparation for a return to operations.

What happened?

Defects were discovered on the davit tilt arms on both the forward and aft legs of two lifeboat davits. Both tilt plates on each leg of the aft davits were found to be cracked and distorted. It was evident after inspection that the initial defects were historical and may have existed for some time unnoticed. The defects may have been compounded by load tests conducted during the recent refit, during which the davits had been upgraded to allow new lifeboats to be installed.

What were the causes?

Following further investigation with the close co-operation of the original equipment manufacturer it was concluded that the defects to the davit tilt arms were caused by the incorrect operation of the davits.

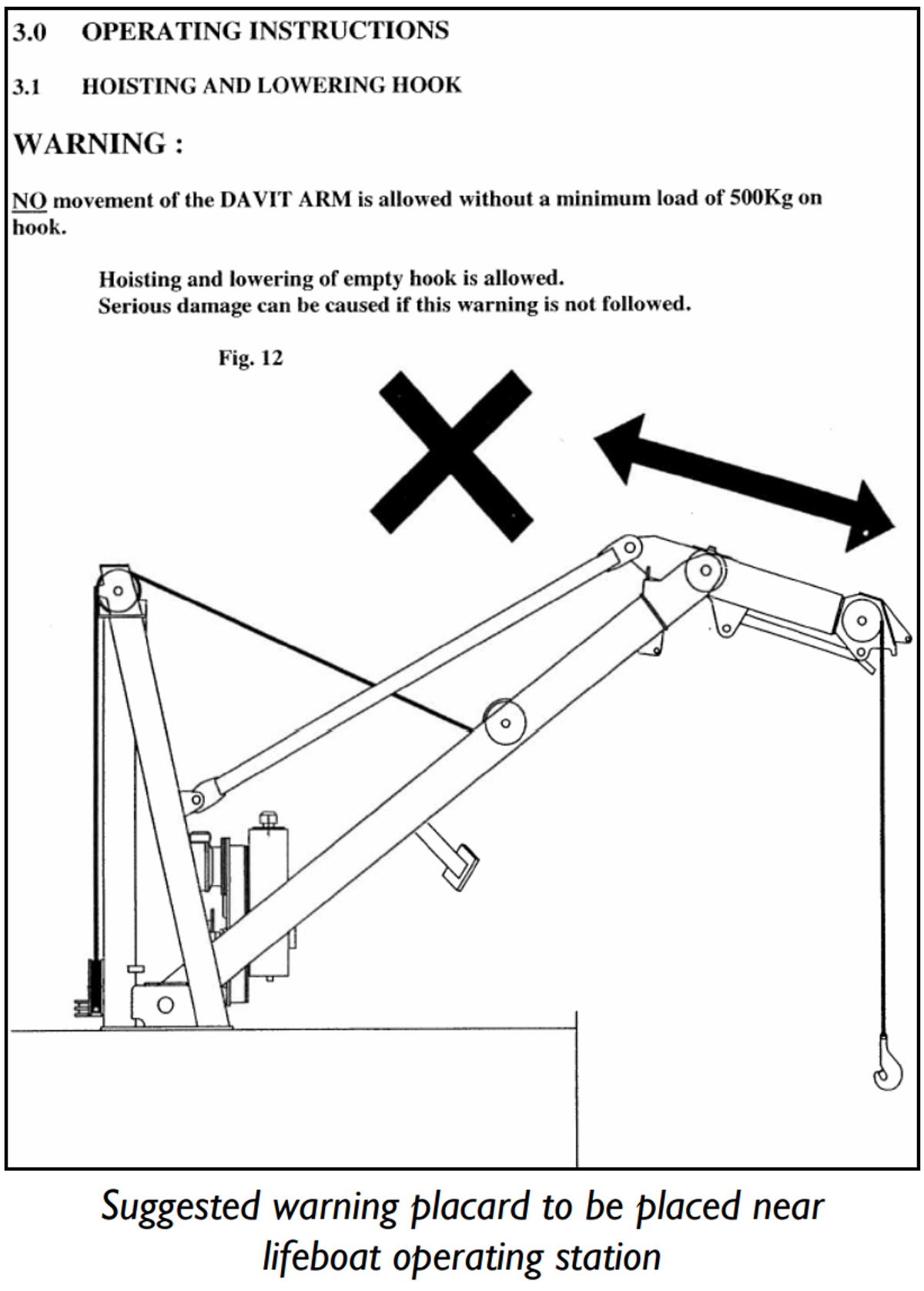

The davit arms had previously been brought inboard of the vessel without the required minimum 500kg weights attached to the davit hooks. A clear warning that this should not take place is included in this specific manufacturer’s documentation.

Lessons learnt

The following actions were recommended:

- The original equipment manufacturer’s documentation for the davits should be consulted and appropriate operating instructions verified to ensure existing practices do not deviate from manufacturer-recommended launching practices, nor compromise the safety and operational integrity of the equipment.

- Davit launch/recovery operators should ensure that the davit is operated in accordance with the guidance provided by the original equipment manufacturer.

- Warning notices should be posted adjacent to each lifeboat operating station (see the diagram below).

- A thorough inspection of tilt plates should be included in monthly planned maintenance checks.

- Since the defects appear to have originated some time in the past, better quality control is required of bi-annual, annual and five-yearly inspections by specialist contractors to ensure that they are conducting the thorough examination of the equipment properly and to an appropriately high standard.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.