Failure of pressure washer

- Safety Flash

- Published on 27 October 2011

- Generated on 23 February 2026

- IMCA SF 11/11

- 2 minute read

Jump to:

A Member has reported an incident in which a Karcher HDS1195 pressure washer failed when a technician was conducting a test run after maintenance.

What happened?

The model involved was a portable unit designed for domestic and industrial use, and was three years old. A technician had completed the replacement of an electrical switch, and was checking that the switch was working correctly. On successful completion of the tests, the unit was powered up to ensure it was fully operational.

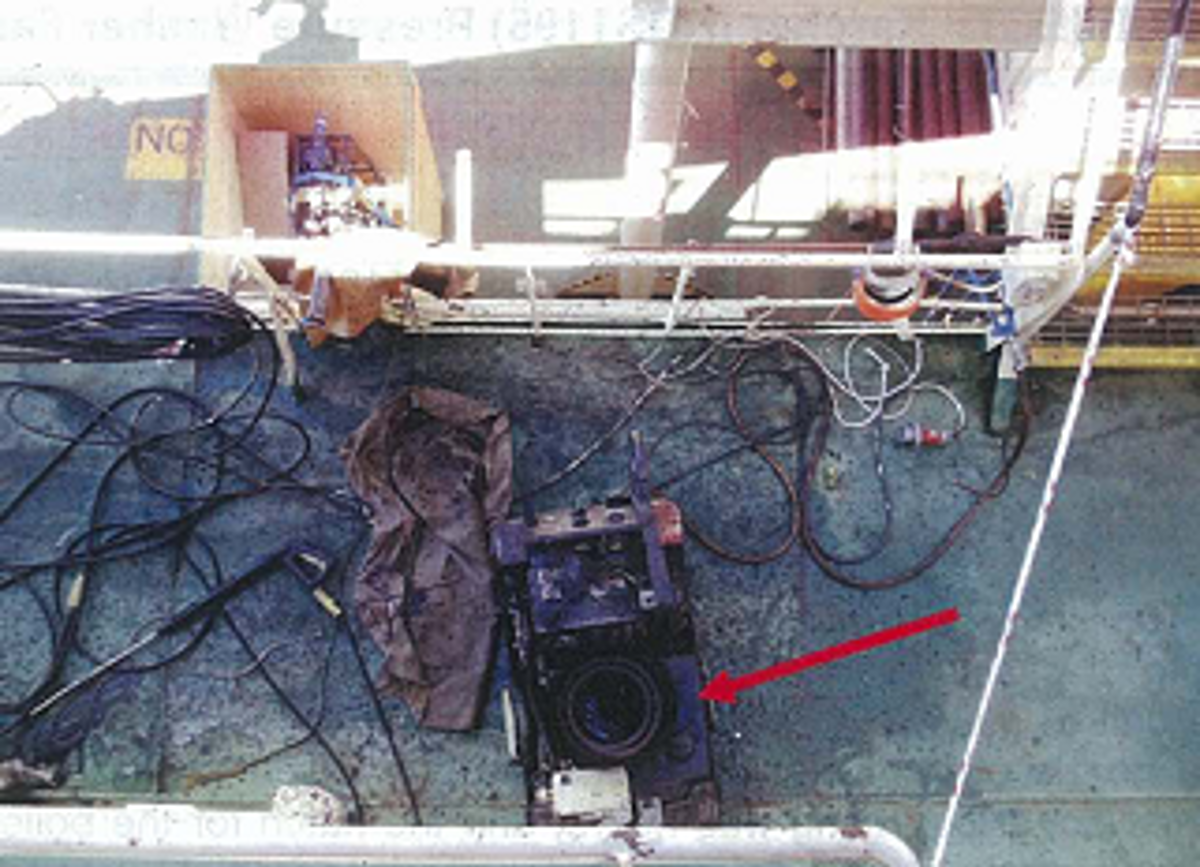

The technician saw water emerging from the nozzle of the cleaning gun, and proceeded to shut down power to the washer. As this was done, there was a loud bang and the hatch for the boiler was blown off into the air. The technician received two small cuts to the face and minor droplet burns to the right arm.

What were the causes?

Investigation revealed that:

- A pressure relief valve, designed to prevent system overpressure, was corroded and unserviceable.

- A switch, designed to regulate the boiler, was also defective.

- As a result, overpressure within the system caused the heating coil to rupture, and the escaping water and steam blew the hatch off the boiler unit and into the air.

Recommendations

The following recommendations were made:

- A thorough inspection of similar portable pressure washing devices, particularly those using a heating system, would be beneficial.

- Portable pressure washing devices should be part of the planned maintenance schedule.

pressure washer with boiler hatch missing

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.