Failure of lifeboat release hook mechanism

- Safety Flash

- Published on 17 July 2014

- Generated on 6 July 2025

- IMCA SF 13/14

- 3 minute read

Jump to:

A Member has reported a recent high potential incident involving the failure of a lifeboat release hook mechanism.

What happened?

The incident took place during the quarterly mandatory lifeboat lowering operations. The forward release hook mechanism opened resulting in the lifeboat dropping into a vertical position, but remaining suspended from the aft hook. Four persons where onboard the lifeboat at the time, but were uninjured.

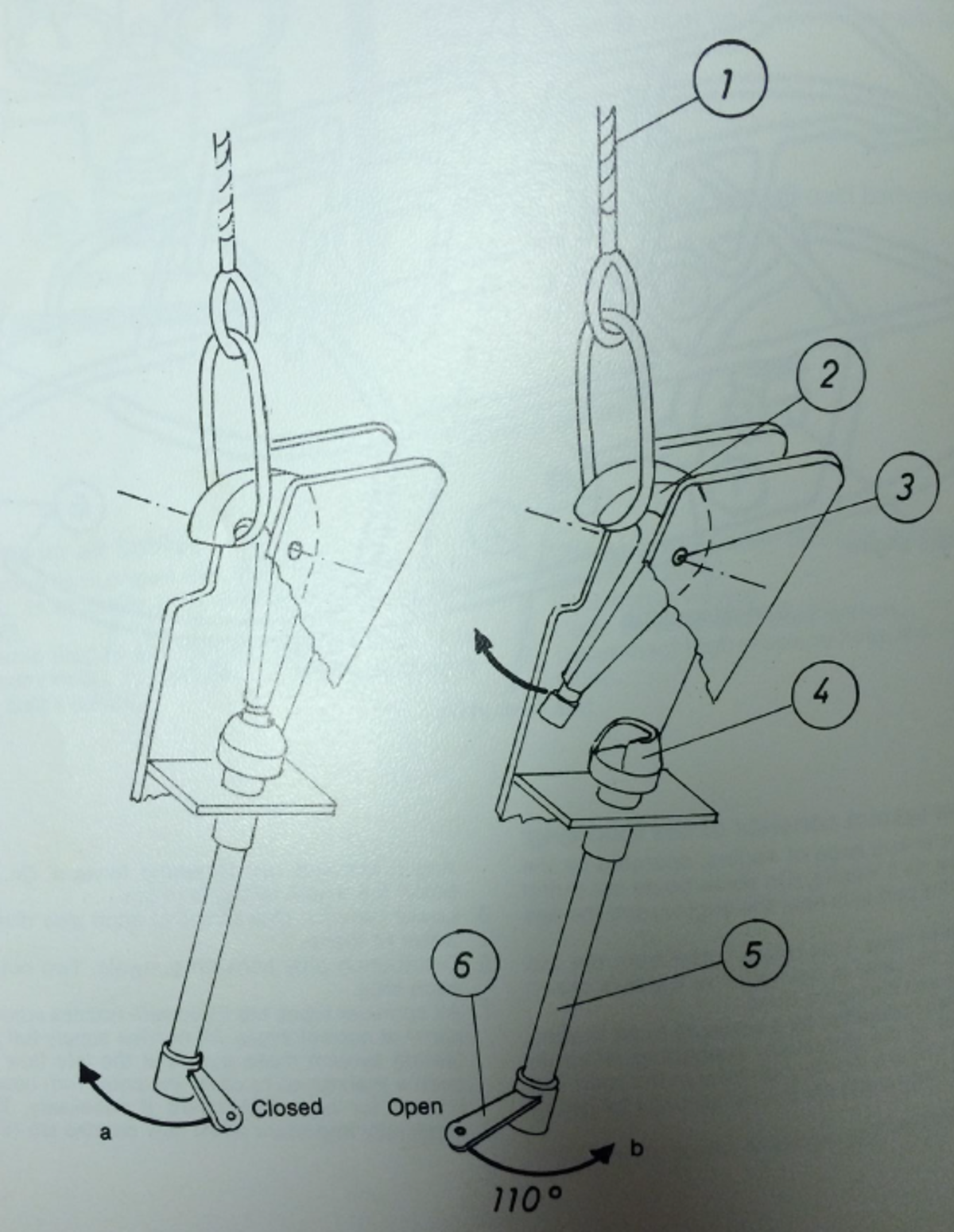

The release hook system in place onboard the vessel is of the Schat-Harding H-80, ‘on-load’ release type. The basic overview of the system is shown in the figure on the left, with the components noted below.

The mechanism is operated from the aft release point, with both hooks disconnected and engaged simultaneously through operation of the aft release mechanism. A linkage rod connects the aft mechanism to the forward mechanism to enable this single instantaneous operation.

The locking lever (component 6) is twisted 110 degrees at the aft release point and this command is replicated at the forward hook release and the main hook lever (locking cup)(component 4) latches or unlatches the release hook.

The current design of the system does not give the operator direct indication that the forward hook is correctly locked. A single indicator serves both the Master (aft) and Slave (forward) locking systems, but only the position of the aft hook is positively indicated.

Lifeboat hook release mechanism

Item Component

| 1 | Davit fall |

| 2 | Aft hook |

| 3 | Hook pivot point |

| 4 | Main hook lever |

| 5 | Locking shaft |

| 6 | Locking lever |

Our member’s preliminary investigation noted that:

- The hook release mechanism linkage was found to have failed (sheared) – see Figure 2 – at the forward end of the lifeboat. This is likely (pending final report) to have been caused by misalignment of the hook during re-attachment and/or fragile design of the hook release mechanism linkage.

- Further inspection onboard found that the forward release mechanism linkage was severely bent (see Figure 3) in one of the other three lifeboats.

- As a result of the above noted damage, a total of two of four lifeboats were found to have release hooks that were not fully engaged.

- Immediate inspection of all lifeboat release hook mechanisms, irrespective of design with the following pointers.

The company has recommended the following actions:

- Check for integrity and potential damage.

- Ensure that the latching mechanism is fully engaged.

- Ensure that there are ‘routine’ checks that all hooks are engaged prior to launch, on completion of recovery and during ‘routine’ lifeboat inspections.

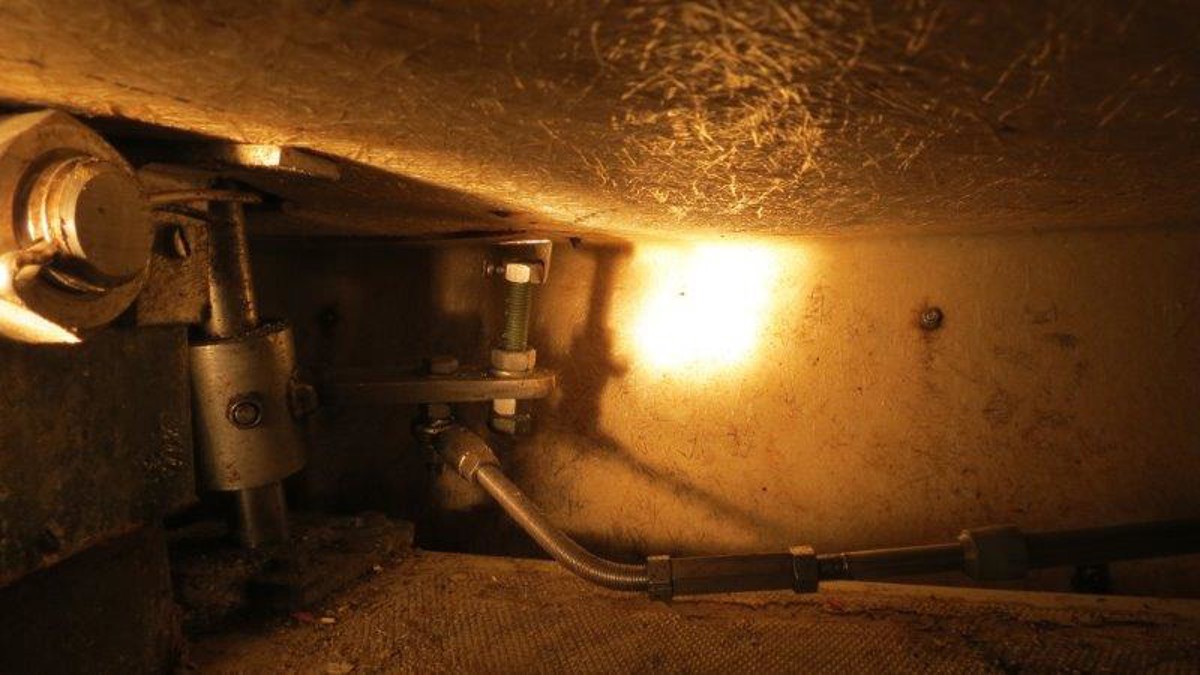

Sheared hook release mechanism from the lifeboat that dropped

This photograph shows the linkage rod that sheared on the forward release hook mechanism on the failed lifeboat. With the linkage sheared, the lifeboat release hook was not fully engaged, resulting in the hook releasing.

Damaged hook release mechanism linkage on other lifeboats onboard

This photograph shows the release hook mechanism linkage at the forward locking mechanism. The arrow indicates the area of severe deformation of the linkage rod, caused by the misalignment of the hook and/or fragile design. The blue line represents the correct alignment of the linkage rod. In this condition, the lifeboat hooks are not fully engaged.

Related safety flashes

-

IMCA SF 13/11

25 November 2011

-

IMCA SF 10/11

16 September 2011

-

IMCA SF 05/02

1 July 2002

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.