UK HSE: Worker fell into lift shaft – safety controls bypassed

- Safety Flash

- Published on 15 April 2020

- Generated on 21 February 2026

- IMCA SF 13/20

- 1 minute read

Jump to:

What happened?

The UK HSE prosecuted a company after a 34-year-old employee was moving a loaded lift trolley in the tool department of a hangar when he fell into the lift shaft to the bottom floor and suffered life-changing injuries.

See here for HSE press release.

What were the causes? What went wrong?

Although the exact cause of the incident could not be established, the HSE investigation found that the lift doors had a fault which meant that they defaulted to locked. As a result, the emergency door release key was being routinely used by employees to bypass the fault and therefore the lift’s safety devices. (IMCA italics)

The HSE inspector said:

“Despite a fault, busy workers who were moving parts and tools felt compelled to keep the lift in use. The safety features of the lift were therefore made redundant. The lift should have been taken out of service or an alternative system of work should have been in place, and this should have been communicated.”

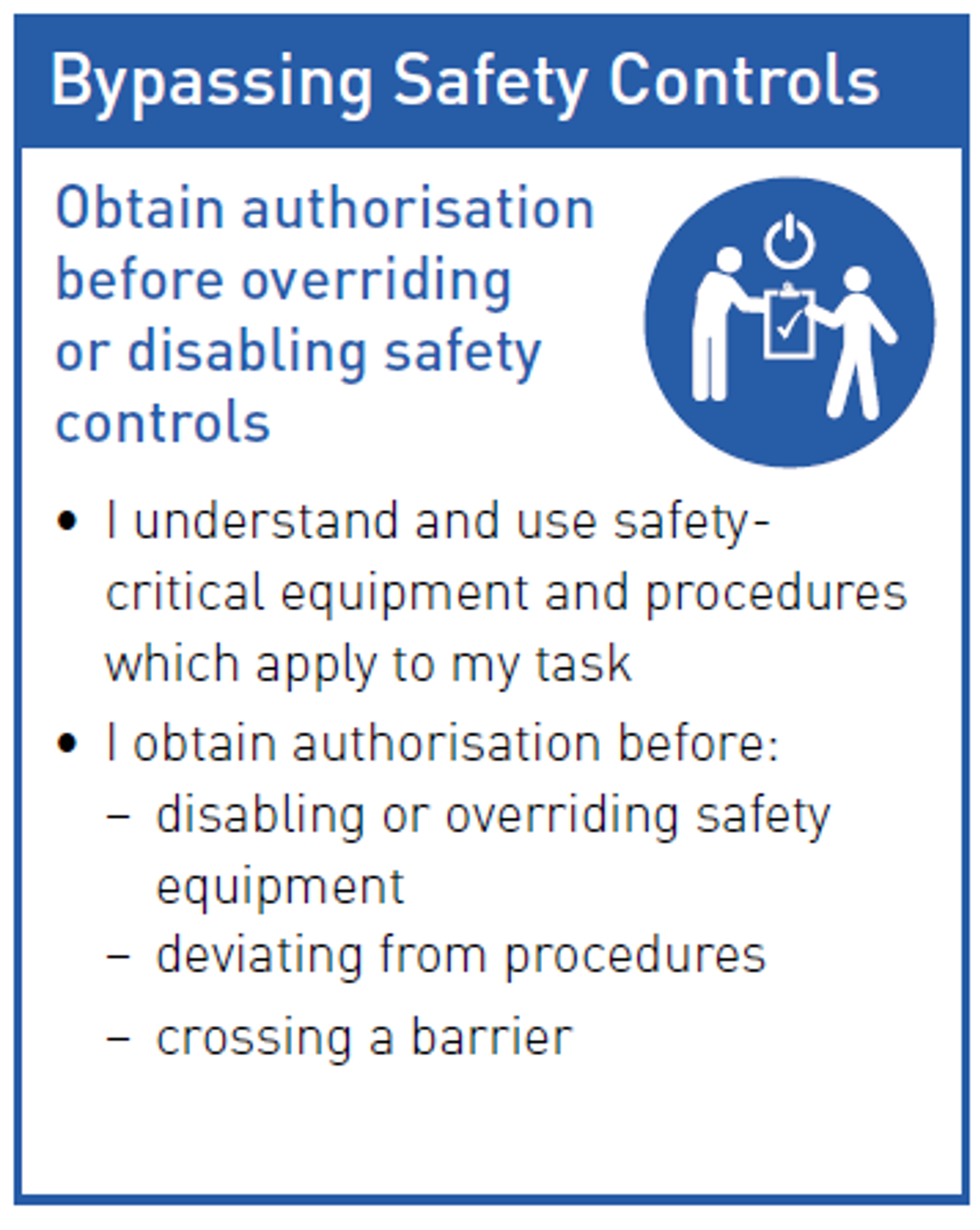

Members may also be interested in the IOGP Life-saving rules report 459.

Related Safety Flashes

-

IMCA SF 22/19

17 September 2019

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.