Hand injury while using manual torque tool

- Safety Flash

- Published on 24 May 2023

- Generated on 12 July 2025

- IMCA SF 13/23

- 2 minute read

Jump to:

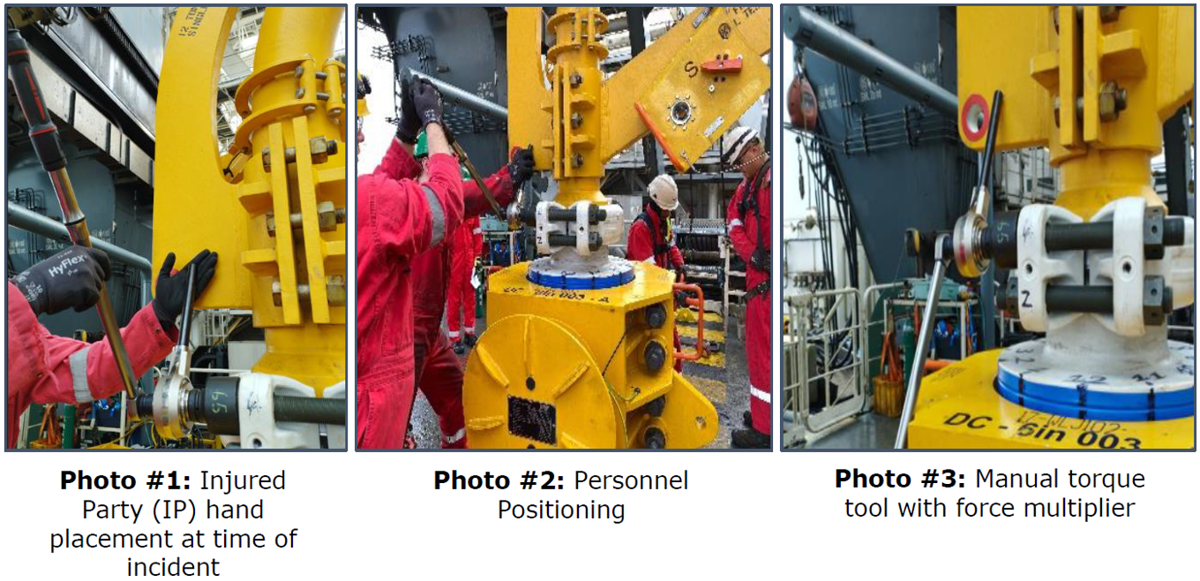

A deck engineer was torquing Grayloc clamp bolts connecting the gooseneck connector onto the second end of a flexible, using a manual torque wrench with a force multiplier attached.

What happened?

A project engineer was in the moonpool area to verify the torque settings on the wrench, as stipulated in the task plan. The project engineer stepped in to assist the deck engineer and they began torquing the bolts together.

During the torquing of the last bolt, the project engineer placed his left hand on the reaction bar of the force multiplier as torque was being applied. His hand slipped and was trapped between the reaction bar and the gooseneck causing a hand injury.

What went wrong?

- Those supervising and those in control of the task did not intervene when the project engineer got involved in the work.

- The pre-job briefing received by the injured person before travelling offshore did not include any advice, in terms of roles and responsibilities, on what activities project engineers do and do not get involved in.

- The project engineer who was injured was not involved in the deck engineer’s Toolbox Talk (TBT) even though he had a specific role in the task plan to verify the torque tool settings.

- The project engineer was not trained or qualified for the task he was participating in.

Actions

- Ask yourself “What should have been done differently?” to prevent this injury event?

- If it’s not safe, stop the job!

- Reinforce the expectations with supervisors to stop work if workers from outside the assigned and briefed work team become involved in the task. The natural inclination may be to offer to help: this is not always safe or appropriate.

- Ensure that the obligation and expectation to exercise stop work authority is clearly communicated and understood by all parties.

- Reinforce the expectations with supervisors to stop work if workers from outside the assigned and briefed work team become involved in the task. The natural inclination may be to offer to help: this is not always safe or appropriate.

- Review inductions for new personnel travelling offshore or to site for the first time. Ensure the induction covers their specific roles and responsibilities on site.

- Ensure that ALL personnel involved in an activity are included in the toolbox talk – and that they can understand what is being discussed in the toolbox talk and what is going on in the task.

- Ensure all are aware that they should be trained on equipment before using it.

Related safety flashes

-

IMCA SF 10/23

20 April 2023

-

-

IMCA SF 21/22

26 September 2022

-

IMCA SF 10/22

21 April 2022

-

-

IMCA SF 23/16

13 September 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.