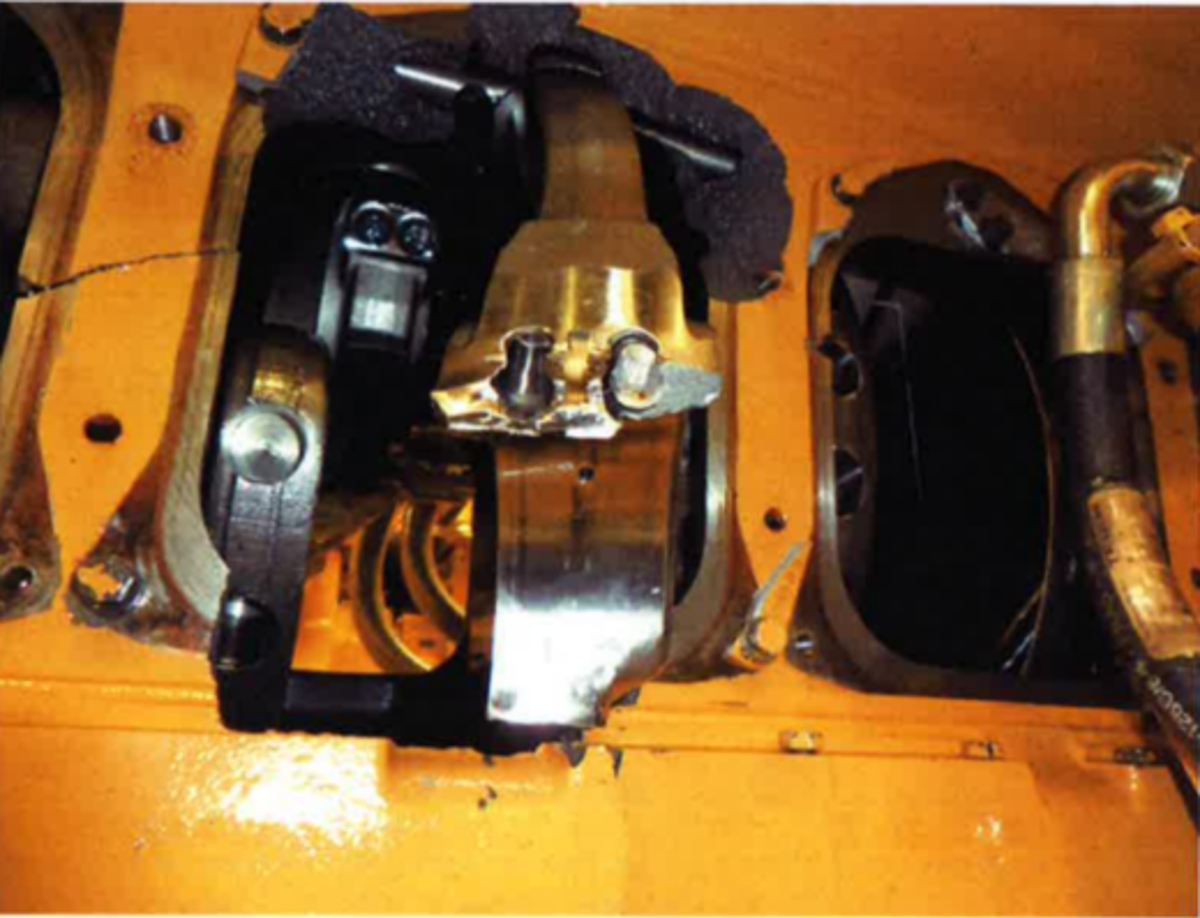

Vessel engine block blown open in and around cylinder

- Safety Flash

- Published on 9 July 2018

- Generated on 16 February 2026

- IMCA SF 14/18

- 1 minute read

Jump to:

A severe engine failure occurred during a major vessel overhaul.

What happened?

The connection rod on cylinder #12 parted from the connecting rod cap and punched a hole in the engine block. The engine had been running for 17 hours, carrying approximately a 20% load.

Parts of the engine block were found spread around the engine room, indicating that the outcome of the event could have been much worse, with potential for personnel injuries and a fire. At the time of the event, the engine room was vacated for lunch. No injuries were sustained, there was no spill of fluids and no fire.

What went wrong?

Failure to change out and correctly torque up four temporarily installed connection rod bolts. The four bolts were temporarily installed. Preliminary investigation revealed high pressure on work schedule, poor handovers, lack of checklists and incorrect marking of cylinder #12.

What actions were taken? What lessons were learned?

Our member noted the following:

- Focus on correct and sufficient management of change (MoC) and handovers processes.

- Use of checklists and marking/signage during work on engines.

- Limit personnel exposure during start-up of overhauled engines.

Related Safety Flashes

-

IMCA SF 07/04

1 August 2004

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.