MAIB: Gantry crane wire parted causing injury

- Safety Flash

- Published on 12 June 2023

- Generated on 2 March 2026

- IMCA SF 14/23

- 2 minute read

Jump to:

A gantry crane hoist wire parted causing a load to drop, causing injury and damage to equipment.

What happened?

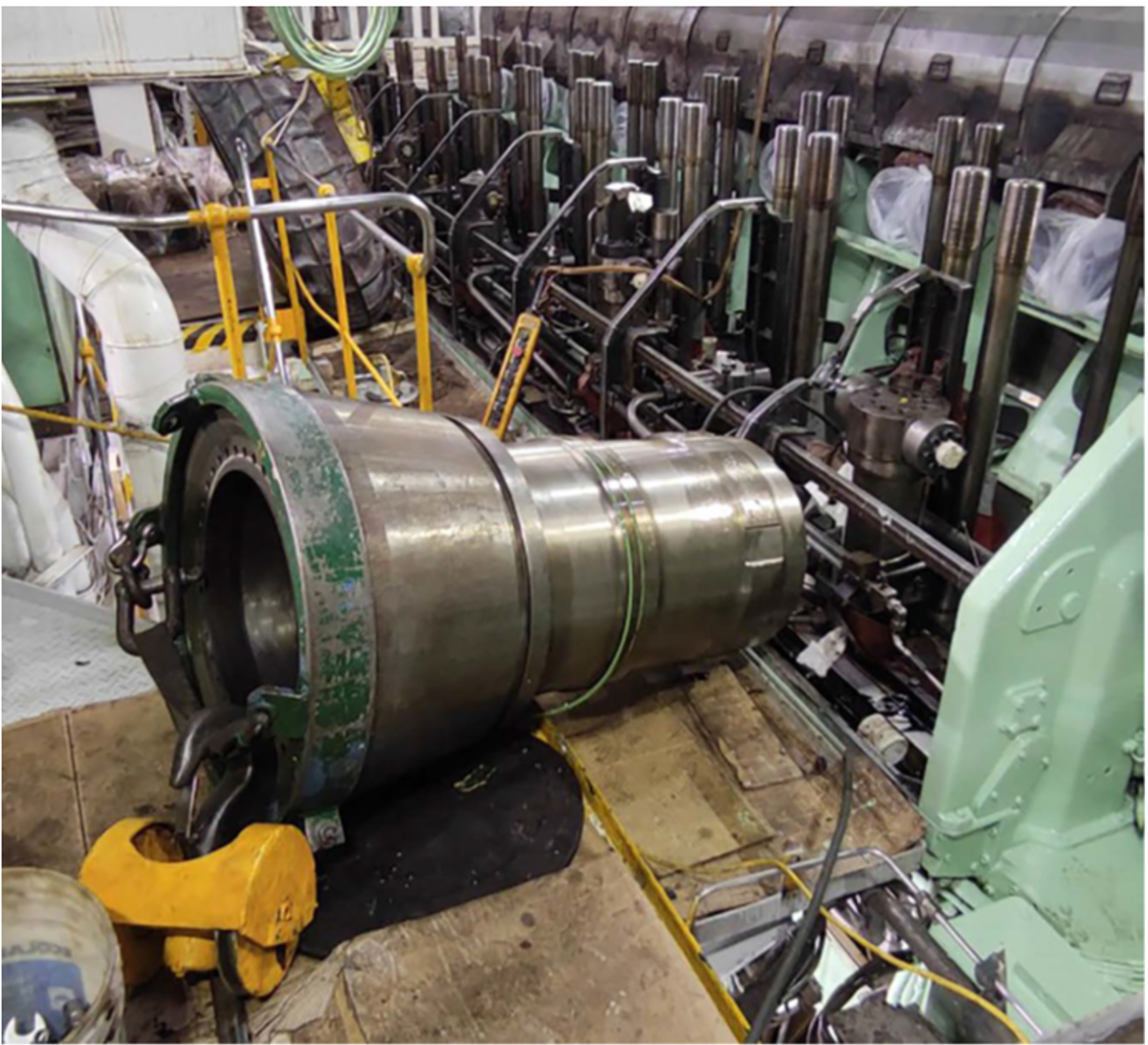

Engineers were overhauling a large diesel generator, using the engine room’s overhead gantry crane to lift a 1200kg cylinder liner into position above the engine.

This required the electric winch motor to raise the crane hook to its maximum lift height, at which point the crane’s hoisting wire suddenly parted.

The suspended cylinder liner fell onto the engine, causing damage to both pieces of equipment, and struck the left foot of an engine room fitter who was standing nearby.

The crew member was treated in hospital for a broken toe.

Cylinder liner after wire parted

Parted hoisting wire

What went wrong?

- The crew member was in the line of fire, near or under a suspended load.

- The failed hoisting wire had been recently renewed but was found to be 7 m shorter than the wire length specified by the crane manufacturer. The shorter length wire affected the operation of the crane’s hoist limit switch and prevented it from cutting power to the winch electric motor when the hook was raised to the maximum lift height; the winch motor was therefore able to overload the wire and cause it to fail.

- It was found that the same potential fault was extant on the other engine room cranes. The wire length recorded in the ship’s planned maintenance system (PMS) computer was found to be incorrect when compared with the manufacturer’s specification.

Actions

- The cranes were all taken out of service for repair. Engineers conducted a full inspection of engine room hoisting devices and take necessary steps to ensure that all equipment meets manufacturer specifications.

- Test hoist limit switches before operating cranes.

Related safety flashes

-

IMCA SF 14/20

28 April 2020

-

-

IMCA SF 25/16

3 October 2016

-

IMCA SF 07/11

19 July 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.