Dropped flexible pipe incident

- Safety Flash

- Published on 16 July 2019

- Generated on 15 July 2025

- IMCA SF 17/19

- 2 minute read

Jump to:

A Member notes an incident during lifting operations, resulting in dropped flexible pipe.

What happened?

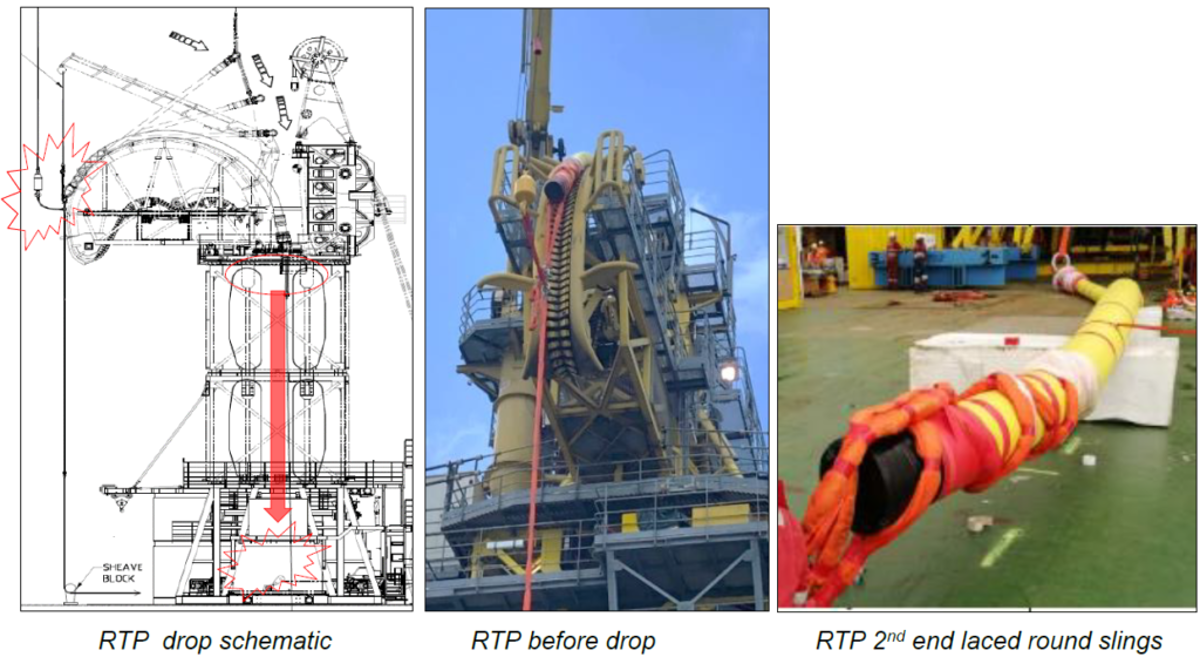

A 6tonne riser test piece (RTP) was being lifted in preparation for load testing the system. The first end was lifted with winch wires attached to both ends. The crane and a 20tonne winch for the first end were connected to the riser via an end fitting pull head. The trailing 10tonne winch (2nd end) was attached using laced round slings. An earlier decision was made to remove the factory end cap and utilize laced round slings instead, but no management of change (MoC) was issued.

The test piece was lifted, and the operation was paused. The tailing winch operator perceived that there may have been insufficient wire on the winch drum to complete the transfer. The decision was made to reverse the lift. As the tailing winch was hauled in, the laced up round sling slipped free off the pipe and the test piece dropped approximately 23 m. A member of the crew had been working in the area where it landed only a few minutes previously.

No persons were injured as a result of this incident; however, it did have the potential to result in a more serious outcome.

What were the causes?

- Lack of intervention at key stages

- Incorrect application of laced round sling configuration

- Insufficient emphasis on preparation; no load test on hold back rigging

- The task was considered routine – a similar operation, although not the same, had been performed on a past project; there was no hazard identification (HAZID) performed on this procedure.

What lessons were learned?

This incident emphasises the importance of:

- having clear, specific guidance for all operations

- ensuring that all equipment is checked and approved prior to conducting a task

- never underestimate the simplicity / routineness of the task.

Our Member recommends a focus on:

- The importance of intervention – accept it, welcome it, expect it.

- Identifying, managing and communicating change using the MoC process.

- Complacency with routine tasks

- Line of fire hazards.

What actions were taken?

- Ensure that all ‘non-standard or non-routine tasks’ are risk assessed and HAZID carried out.

- Prepare clearly defined guidelines for laced round sling configurations and circulate consistently across fleet.

Related Safety Flashes

-

IMCA SF 20/18

10 September 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.