High potential near miss – Storage box dropped from forklift

- Safety Flash

- Published on 16 July 2019

- Generated on 6 July 2025

- IMCA SF 17/19

- 2 minute read

Jump to:

A storage box weighing approximately 770 kg fell 4 m from the forks of a forklift truck.

What happened?

The incident occurred when storage boxes containing items of equipment located on an intermediate floor at a supply base were being lifted from the level using a forklift truck.

This near miss was categorised as a high potential event.

What went wrong?

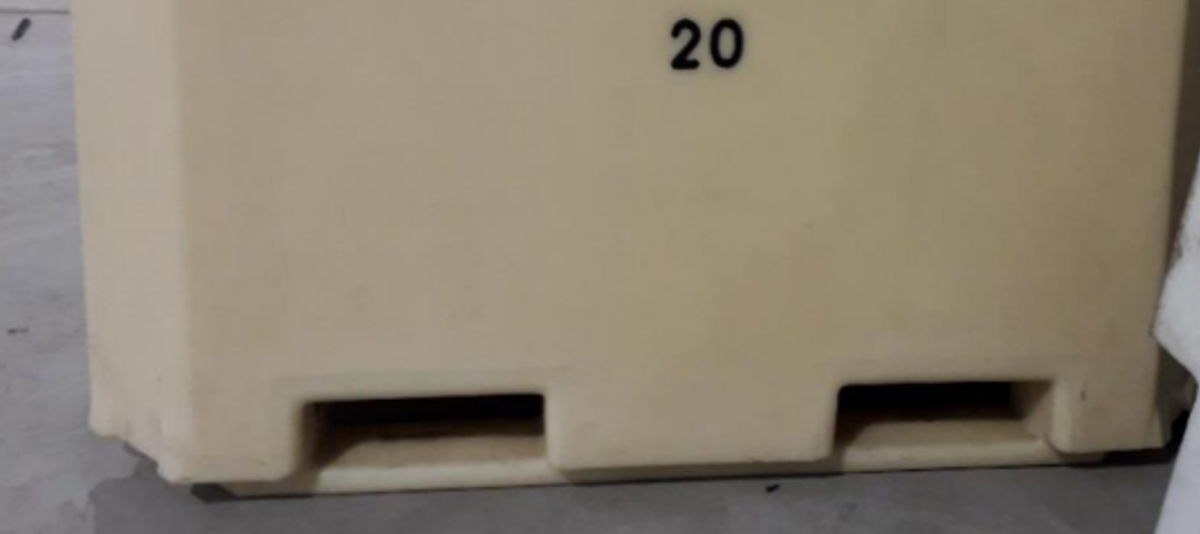

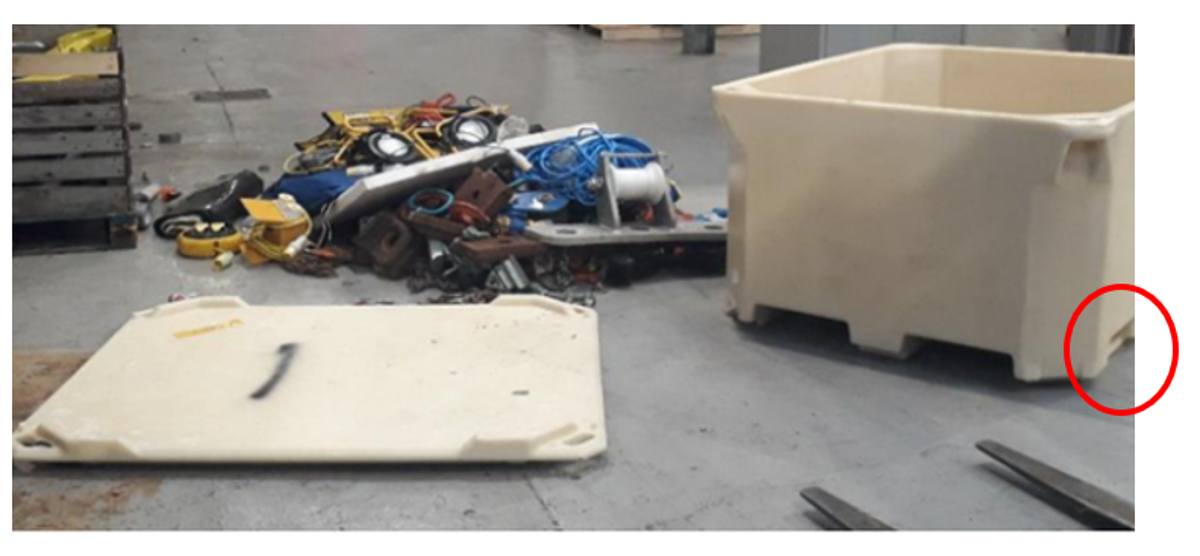

Investigation has identified the storage box was not lifted correctly; it was not lifted from the captive pockets.

If the captive pockets had been used, the bottom edge of the box should make contact with the fork itself, preventing tipping forward from the forks.

The ‘captive pockets’ can be seen in the right-hand photograph below, and also in the extreme right of the photograph above (circled).

What were the causes?

Poor communication: the above was identified and followed on all the previous box retrievals.

However, this was not communicated to new personnel joining the task which led to the (dropped) box being lifted from the non-captive pockets.

What lessons were learned?

- Review instructions on how items are identified, weighed, stored and handled.

- The lifting location of this box type should be clearly marked and visible from ground level.

Related Safety Flashes

-

IMCA SF 23/16

13 September 2016

-

IMCA SF 14/16

17 May 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.