Painter parted during small boat operations

- Safety Flash

- Published on 25 July 2017

- Generated on 25 February 2026

- IMCA SF 18/17

- 2 minute read

Jump to:

The Marine Safety Forum (MSF) reports an incident in which the forward painter quick release on a fast rescue craft (FRC) parted during recovery of the boat. Three crew members were in the FRC.

What happened?

During recovery of the FRC, the forward painter quick release parted just as the FRC was lifted out of the water. The FRC then swung to starboard causing the stern to come into contact with the mother vessel. The jet guard struck the side of the vessel and the jet itself struck the side of the vessel.

The FRC bucket was cracked, as was the jet inside the bucket and the jet guard was found slightly bent. The FRC was recovered with no injuries to the crew-members.

What went wrong? What were the causes?

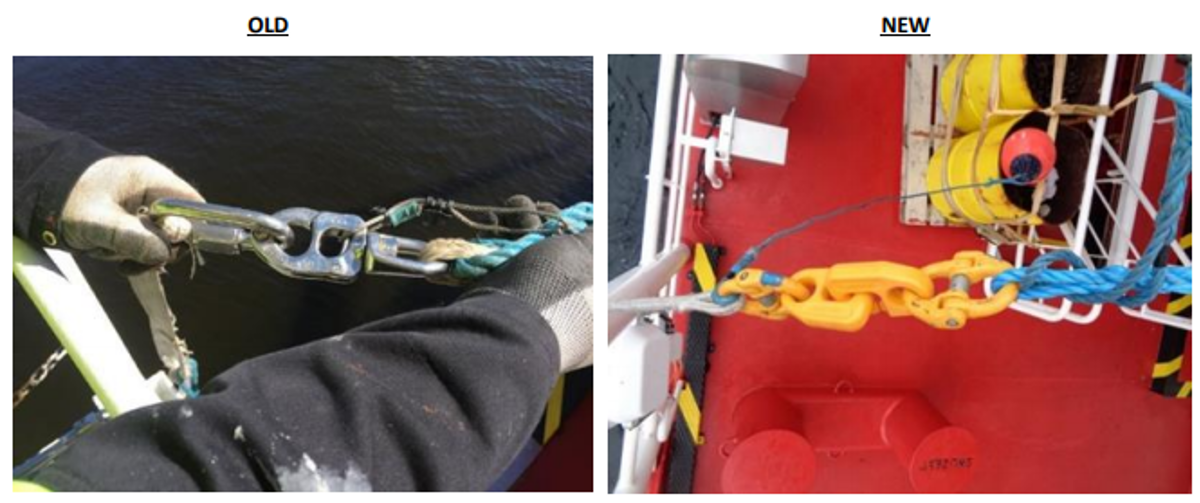

- The forward painter quick release mechanism used had no time limit for use nor inspection criteria, and had been in operation for two years.

- A previous near miss had been recorded where the clip had parted resulting in a visual inspection of the ‘outside’ of the quick release where the spring mechanism cannot be viewed.

What lessons were learned? What actions were taken?

The incident happened in calm summer conditions. The crew were briefed and trained (irrespective of weather conditions) to brace themselves and hold on tightly when being lifted; had this not been the case then there was potential for injury or fall from the FRC.

The springs inside the quick release clip will deteriorate with weather exposure and high usage and cannot be viewed from the outside. There were no records of inspections within the planned maintenance system.

The following corrective actions were carried out:

- The quick release mechanism was replaced immediately with a G-link type, eliminating the spring mechanism.

- Planned maintenance system – 6 monthly visual inspection implemented.

- Risk assessment reviewed.

- All crew reminded to be conscious of dangers at all times – complacency is not an option!

Related safety flashes

-

IMCA SF 13/11

25 November 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.