Mattress beam landed very close to divers

- Safety Flash

- Published on 25 July 2019

- Generated on 7 March 2026

- IMCA SF 18/19

- 2 minute read

Jump to:

During subsea lifting operations with divers in the water, a large mattress lifting beam was lowered inappropriately close to the divers.

What happened?

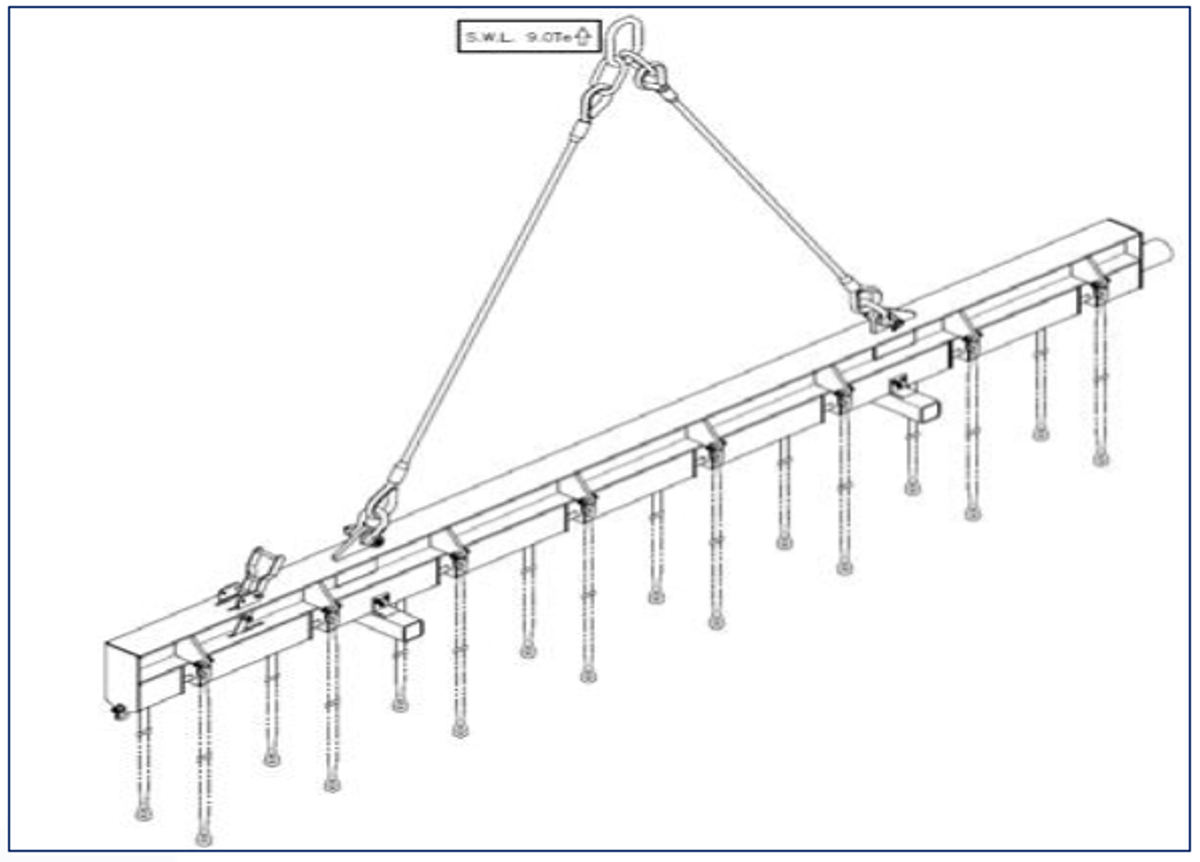

The two saturation divers were deployed on the seabed at 156 msw, assisting with concrete mattress recovery using a mattress lifting beam attached to the vessel main crane. The beam weighed 696 kg in seawater.

What went wrong?

Investigation showed:

- Dive team lost sight of the beam during descent, due to:

- lack of due care and attention to load coming down.

- ROV was on seabed, and did not provide eyes on load from established short mark

- poor visibility.

- lack of due care and attention to load coming down.

- Failure to stop the job:

- acceptance of risk and failure to reassess the situation post-incident.

- failure to properly record and report events to management onboard at the time of the incident.

- acceptance of risk and failure to reassess the situation post-incident.

What actions were taken?

Our member undertook to check that company procedures were being properly followed with regard to ensuring that:

- Divers are clear of moving loads and maintain a safe distance at all times – not under the load nor in the ‘DROPS cone of exposure’.

- The divers can see the mattress beam and are in a position to control the lowering of the load by relaying instructions to the crane operator via the dive supervisor.

- There is an ROV to determine water depth and height of subsea assets, locate the mattress beam and confirm its status.

- The crane wire/lifting beam is fitted with mini beacon, light sticks, strobes etc as appropriate and is lowered to the ‘short mark’ above the assets or the seabed.

- The beam deployment is conducted at a minimum distance offset from client assets.

- The crane line out meter is zeroed when loads pass through waterline.

- Reaffirm requirements of company incident reporting process.

Members may wish to refer to the following IMCA guidance documents:

- IMCA D060, HSS019, LR006, M187 - Guidelines for lifting operations

- IMCA D046, LR013, M205 - Guidance on operational communications

- IMCA D014 - IMCA international code of practice for offshore diving

Related Safety Flashes

-

IMCA SF 10/12

11 October 2012

-

IMCA SF 13/11

25 November 2011

-

IMCA SF 04/04

1 May 2004

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.