Chain caught and broke

- Safety Flash

- Published on 24 July 2023

- Generated on 3 March 2026

- IMCA SF 18/23

- 2 minute read

Jump to:

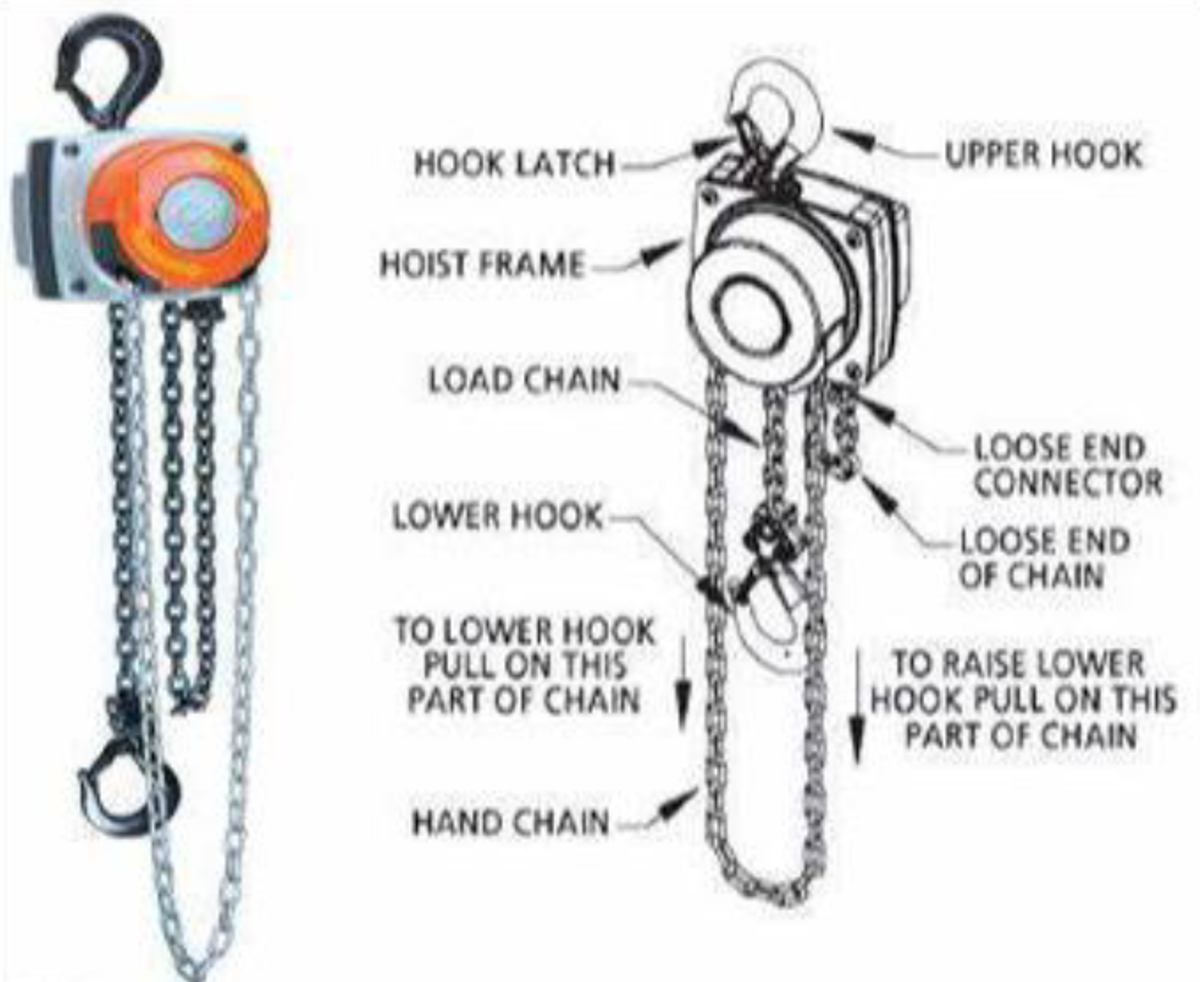

Crew were removing a hydrogen gland from a generator using a lifting attachment, two chain falls, and an overhead crane.

What happened?

One of the chain fall’s pull chains caught on a bolt and broke. The bolt was on the top of the generator and was there to hold a protective cover sheet in place.

There were no injuries.

What went wrong?

- There was a general job briefing done for the day’s work, but not specifically for this task.

- The crew had started lifting the load with chain falls and were beginning to lift with the crane.

- There are two distinct lifts to be considered – the manual lift (with the chain fall) and the power lift (with the crane). The transition is the critical time.

- There are two distinct lifts to be considered – the manual lift (with the chain fall) and the power lift (with the crane). The transition is the critical time.

- Everyone was focused on the load and not watching the chain falls or the crane.

Actions

- A safety stand-down was held to discuss this incident with all involved and lessons from it were to be included in future training material for apprentices and new hires.

- Have an increased awareness of ensuring chains are free when moving loads.

- Keep the “bigger picture” in mind – don’t get so focused on the detail that something obviously potentially unsafe escapes your attention.

Related Safety Flashes

-

IMCA SF 10/20

17 March 2020

-

-

IMCA SF 01/15

16 January 2015

-

IMCA SF 07/10

10 November 2010

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.