Unintentional release of diving helmet – neck dam/helmet securing arrangements

- Safety Flash

- Published on 2 August 2016

- Generated on 9 February 2026

- IMCA SF 20/16

- 1 minute read

Jump to:

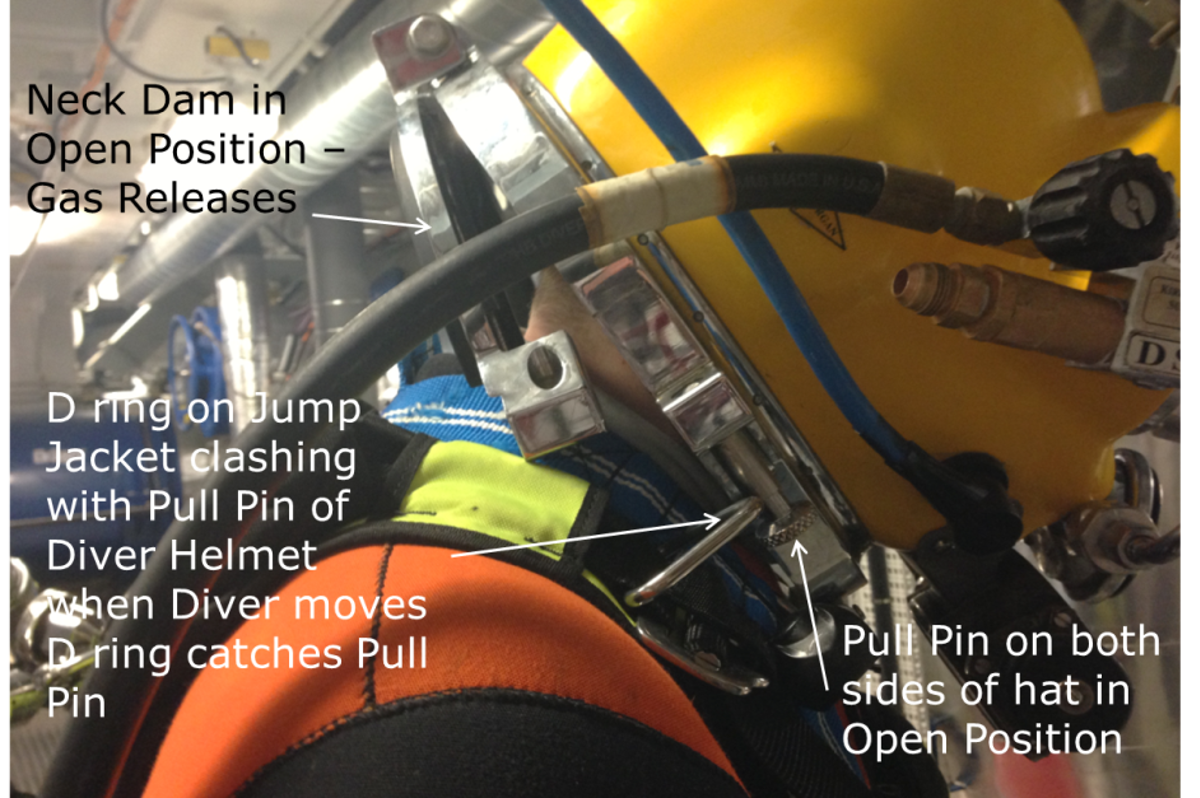

A Member reported two incidents in which there has been unintentional release between neck ring and helmet on a KM17C diving helmet during saturation diving operations.

What happened?

Members are encouraged to ensure that diving personnel are aware and that they check the interface between helmet and its securing arrangement towards other equipment supporting the diver. Working conditions could also give same results, e.g. working close to (taut) wires or large insertion bolts, etc.

Our member identified the following corrective actions:

- Verify that interface between helmet and other diving equipment is such that it cannot hook up the release mechanism.

- Be aware of the potential of release such that operational measures could be taken to prevent this.

- Report any further problems (with helmet and locking mechanisms) immediately.

Incident details

The manufacturer has developed a pull pin sleeve, which may also work to prevent this from recurring. See the Kirby Morgan website for more details.

A series of photographs follows for illustrative purposes:

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.