Two serious dropped object near miss

- Safety Flash

- Published on 10 September 2018

- Generated on 6 March 2026

- IMCA SF 20/18

- 3 minute read

Jump to:

Two further dropped object cases have been reported recently, highlighting the extreme danger and potential for fatalities.

Incident 1

A light and fitting on a third-party ship, weighing 8kg, fell 20 metres to the deck narrowly missing one of the crew members. The light was fitted to a post which had previously been identified as heavily corroded.

Findings

The corroded item had previously been identified by the ship owners, but no corrective action was taken to secure the light and remedy the situation. Subsequent inspection by our member identified other items at risk of falling.

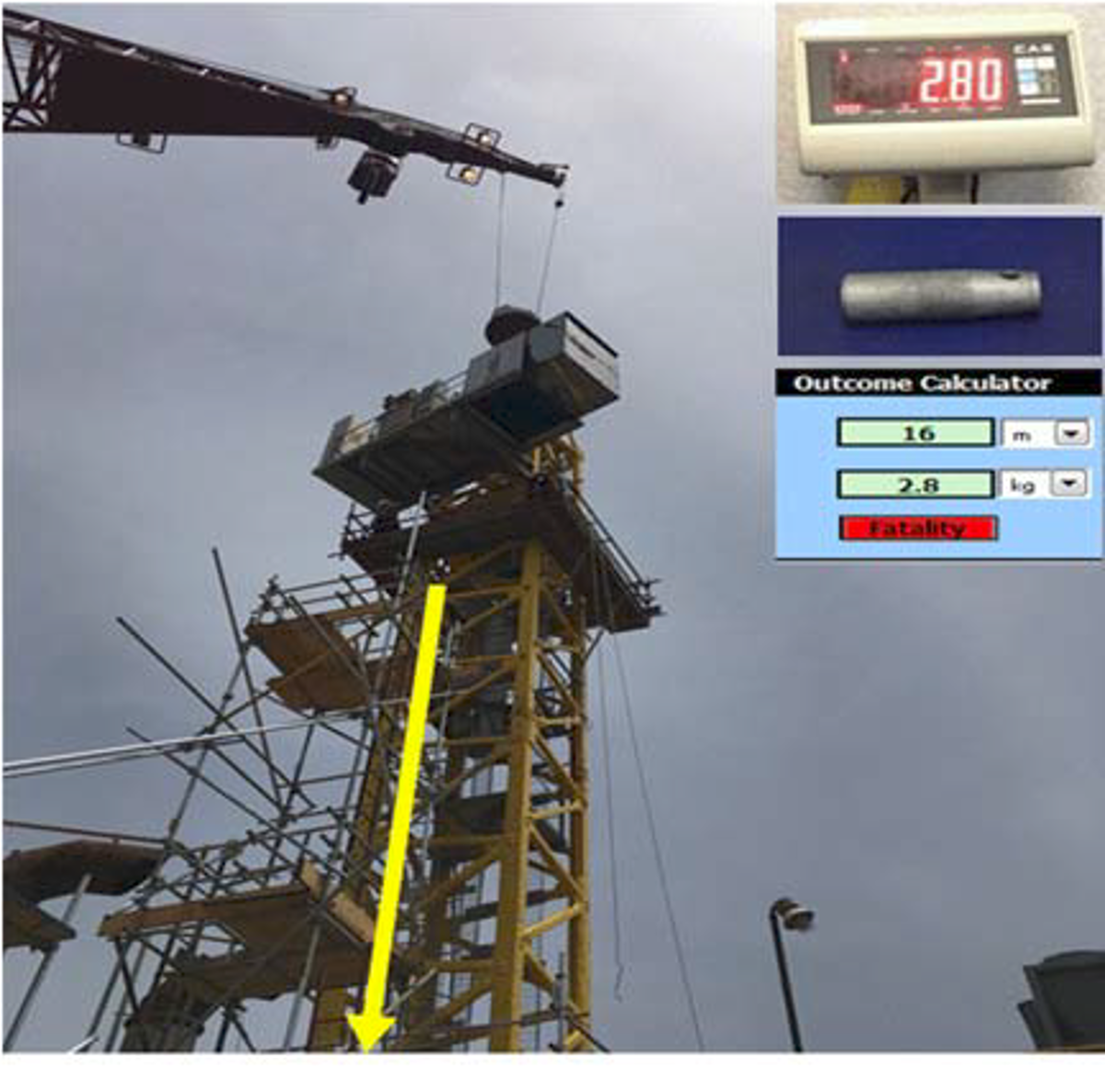

Incident 2

A 2.8kg steel pin fell 16 metres to the deck. The area immediately below the drop area had barriers set, however if the pin had hit the structure and was deflected it could have endangered the deck crew.

Findings: the task was not planned, or risk assessed correctly:

- The removed pin was placed on the tower structure instead of in a scaffold clamp type basket.

- The rigger was unfamiliar with the task and was not made aware of the required rules when working at height.

- Tools in use by the work team did not have the required lanyards and could have also fallen to the deck.

What lessons were learned?

Our member recommended:

- Outstanding defects that pose a risk of dropped objects should be categorised as dangerous and either removed or rectified.

- Worksite management should ensure that only the correct secured tools are used when working at height.

- Tools used at height should be fitted with the appropriate securing devices to prevent them falling.

- Ensure that all work at height is subject to a specific risk assessment which addresses the potential for dropped tools and work equipment, and identifies the controls to prevent this happening.

- Barriers under towers should be set at a sufficient distance considering the possibility of items deflecting off any structures.

- Prior to third-party vessels being taken on hire, evidence should be produced by the owner to prove that there has been a DROPS survey conducted, and a regime is in place to inspect, maintain and correct any defects affecting the security of equipment at height.

DROPS is a key safety focus. For more information on DROPS, visit http://www.dropsonline.org/resources-and-guidance/poster-selection/, for industry guidance, posters, presentations and good practice hints and tips.

Members may wish to refer to the following:

Related Safety Flashes

-

IMCA SF 11/15

10 August 2015

-

IMCA SF 14/14

7 August 2014

-

IMCA SF 08/12

24 July 2012

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.