Recurring Hand Injury

- Safety Flash

- Published on 25 September 2018

- Generated on 2 March 2026

- IMCA SF 22/18

- 2 minute read

Jump to:

The Bureau of Safety and Environmental Enforcement (BSEE) has published Safety Alert No. 336 regarding a hand injury sustained during lifting procedures.

During a slow lifting process to remove a rubbish bag from a storage container, the storage container itself also began to lift. The crane operator was unable to see the lifting operation due to a blind spot, and therefore had another employee guiding him through the lift. The employee placed his hand on the container in order to free the bag. As the container began to lift, the metal frame began to part, which caused the container to fall onto the production deck and the individual.

The employee was left with a large laceration (see image) on his left hand, which required 8 stitches.

What went wrong?

- The correct personal protective equipment (PPE) was not worn by the employee guiding the crane operator.

What action was taken?

- The storage container was removed from service and discarded.

What lessons were learned?

- Offshore personnel should always wear appropriate PPE when performing tasks.

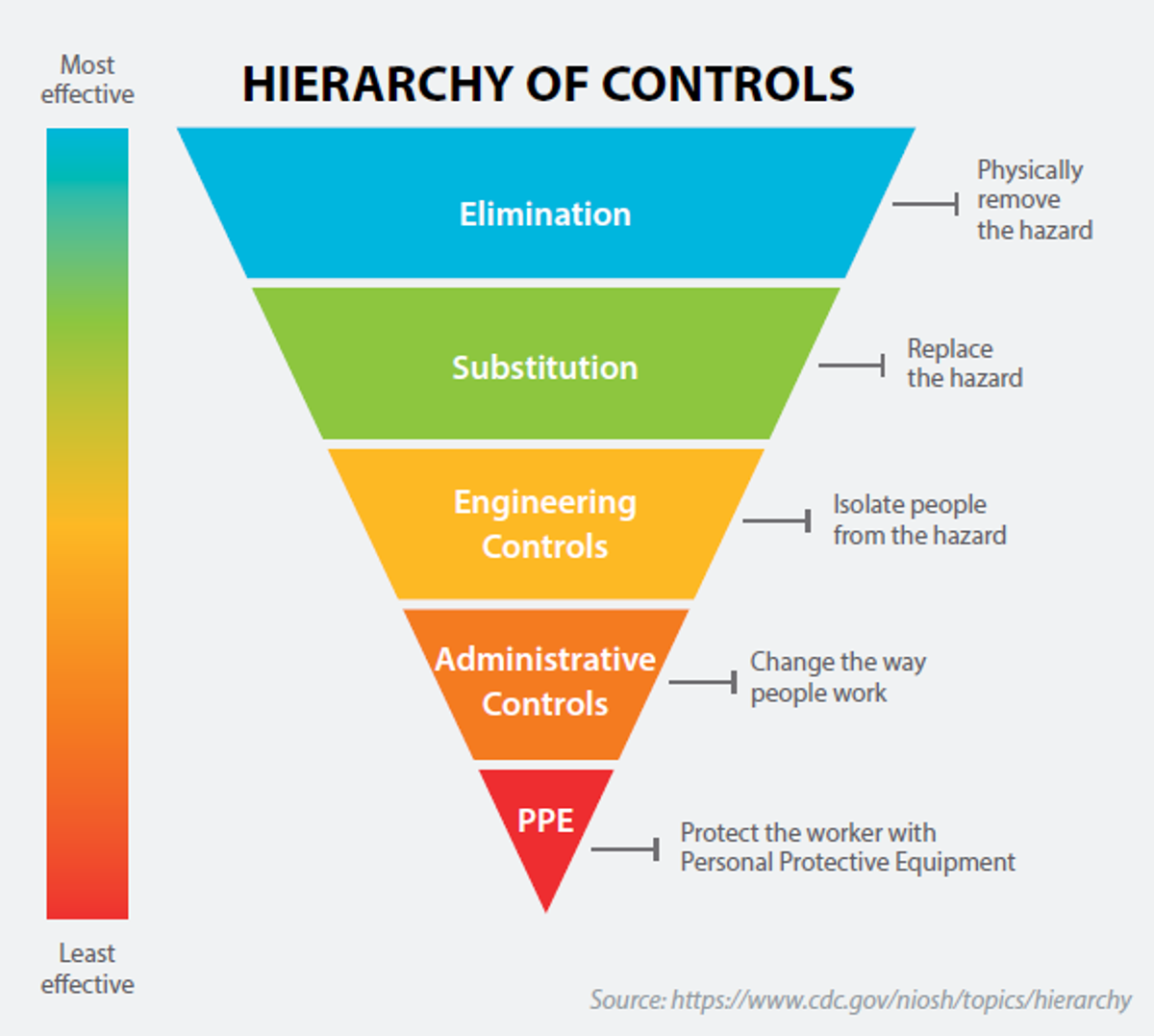

- The BSEE also recommends that operators use job safety analyses (JSAs) on each job/task undertaken and ensure that they properly identify the risks and hazards of the job, and to mitigate the risks to as low as is reasonably practicable (using the hierarchy of controls promoted by NIOSH).

The BSEE noted that there has been a large number of hand injury incidents, which range from burns and cuts to blunt trauma. Further information on these incidents can be found in the BSEE Safety Alert No. 336.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.