BSEE: person fell through open hatch

- Safety Flash

- Published on 11 November 2024

- Generated on 7 March 2026

- IMCA SF 22/24

- 2 minute read

Jump to:

The United States’ Bureau of Safety and Environmental Enforcement (BSEE) has published Safety Alert 489 relating to a person who was injured after a fall through an open hatch. The alert reiterates the need to remain vigilant of your surroundings.

What happened?

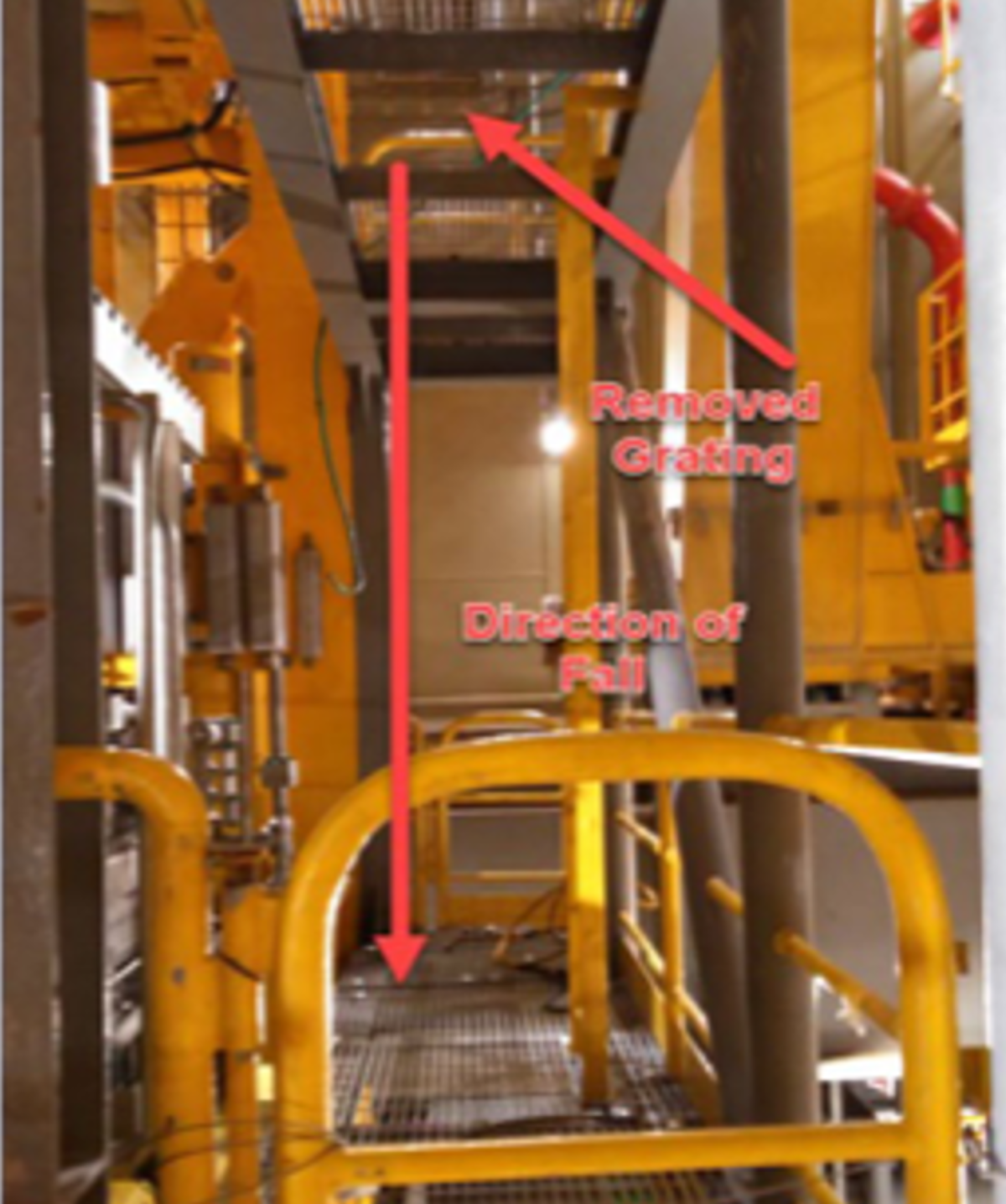

A worker on a blowout preventer platform fell through an open hatch cover that had been removed due to damage. The worker sustained injuries to his leg and knee.

Swipe to see next image

What went wrong?

Multiple factors contributed to the incident, including a lack of situational awareness for potential hazards, inadequate fall protection measures, and the failure to 1) properly secure the hatch covering the hole, 2) take corrective action after the cover was removed, and 3) alert other personnel to the hazard.

The BSEE notes that the offshore environment can present challenging and potentially dangerous working conditions that require constant situational awareness. Everyone should be reminded of the importance of situational awareness and continuously checking your surroundings for potential hazards. Situational awareness applies to various work situations, including loose grating, damaged handrails, hot work areas, loads being lifted above or around you, red zones, and production and well operations related to pressure. This vigilance can be the difference between life and death.

Actions suggested

BSEE recommends that operators and their contractors, where appropriate, consider doing the following:

- Check your surroundings prior to starting work for any potential hazards.

- Identify and document hazards and then communicate these to all personnel.

- Ensure the proper fall protection is used when working at heights.

- Check temporary equipment and work platforms for hazards prior to use.

- Use a spotter to help identify and communicate any hazards when working at heights.

- Install barricades and “flag up” areas with questionable walking or working surfaces. Soft barricades (e.g., caution tape) may be temporarily used, but hard barricades should be installed.

- Ensure ladders that connect decks have safety gates that swing closed when not held open.

- Remind personnel to stay vigilant of their surroundings when working on or near elevated work platforms.

- Remind personnel to work at a pace that allows for continual reassessment of dynamically changing work environments.

- Follow approved procedures for the work being performed and outlined in the job safety analysis.

Related Safety Flashes

-

IMCA SF 18/23

24 July 2023

-

-

IMCA SF 24/23

16 October 2023

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.