Property damage: Platform supply vessel collided with legs of jack-up rig

- Safety Flash

- Published on 21 September 2017

- Generated on 3 March 2026

- IMCA SF 23/17

- 2 minute read

Jump to:

A Platform Supply Vessel (PSV) collided with the legs of a jack-up drilling rig, causing some damage to the PSV.

What happened?

The incident occurred after transfer of water to the rig. The PSV had been ready to disconnect the hose, but the rig informed the PSV that there would be a delay. The PSV was to the windward (weather) side of the rig and the weather was “rough”, with the wind approximately 22 knots.

A little under an hour after completing transfer of cargo, but whilst the hose was still connected, the PSV starboard engine and thrusters tripped. As a result the PSV started to moved astern and to Starboard. DP control was immediately transferred to manual mode. The hose was dropped in the water. Whilst pulling away to safety, the PSV made contact with the forward leg of the drilling rig.

dent in PSV as a result of collision

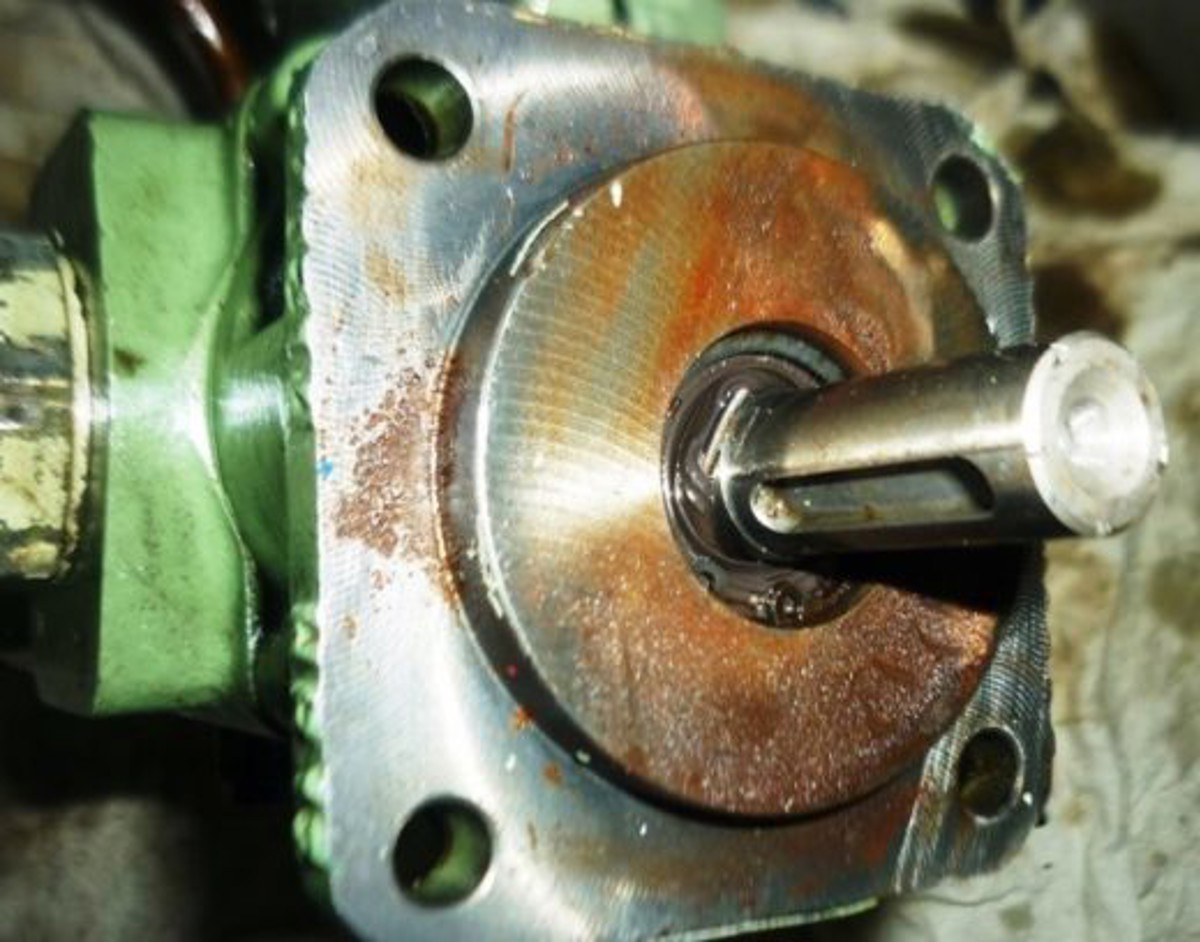

damaged fuel oil pump

What went wrong? What were the causes?

- Procedures were not followed: Vessel working on the weather side as the jack-up rig was not geared up to receive water on the lee side.

- Equipment: Mechanical seal of fuel oil pump was damaged suddenly indicating material failure.

What lessons were learnt? What actions were taken?

- Better management and assessment of risk during simultaneous operations – if required, the vessel should come off and get out of the safety zone.

- Whilst material failure of items can be unpredictable, planned maintenance schedules and manufacturer’s instructions should be followed for critical equipment.

Related safety flashes

-

IMCA SF 07/17

28 March 2017

-

-

IMCA SF 12/15

28 August 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.