Lost time injury (LTI): Loose grating fell from crane, a man fell through and was injured

- Safety Flash

- Published on 5 October 2017

- Generated on 10 July 2025

- IMCA SF 24/17

- 2 minute read

Jump to:

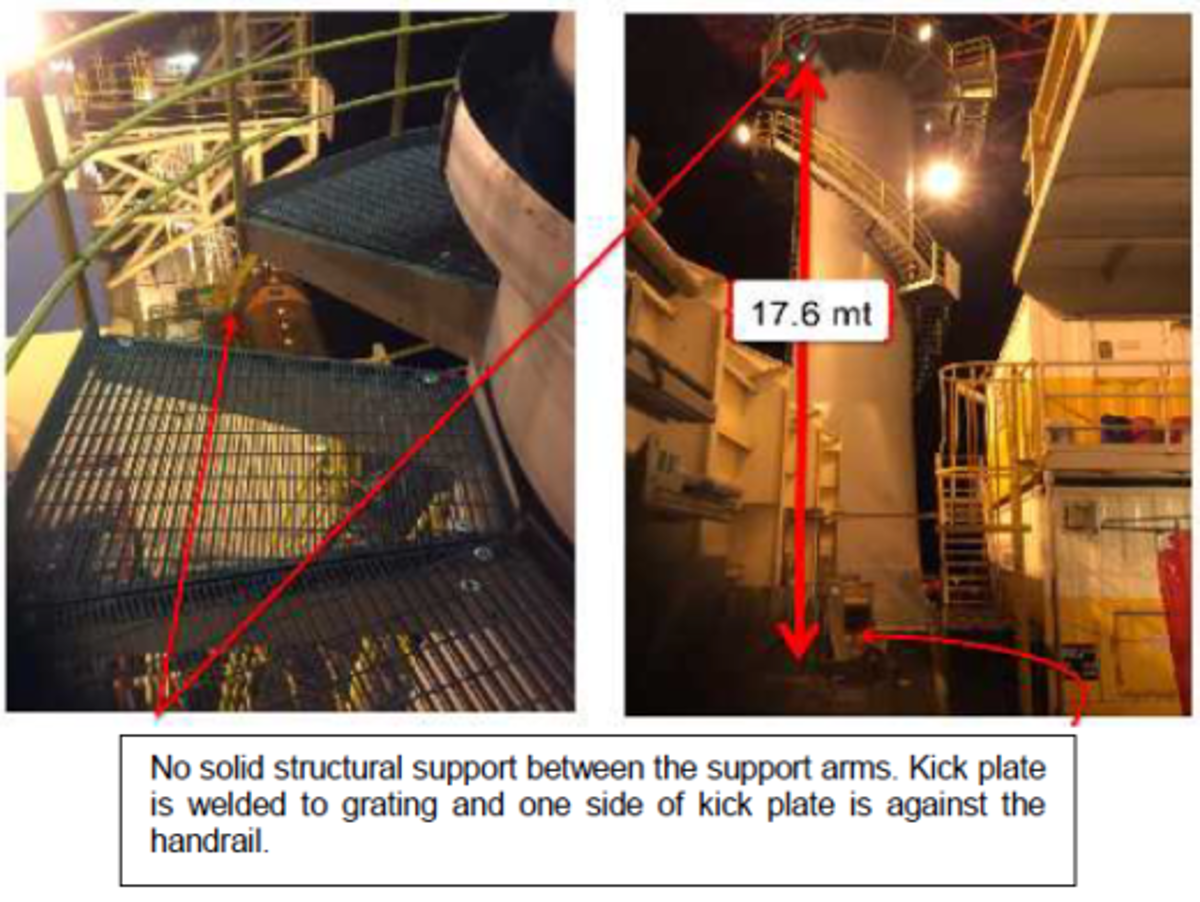

A crane operator stepped on a loose piece of grating on the crane walkway. The grating fell 18 m to deck below, damaging some stairs. The crane operator fell 4.5 m through the open grating, and suffered a fractured left leg.

What happened?

The incident occurred after the crane block hit the walkway during lifting operations, when the crane was completely boomed up to reach the load.

The crane block began to swing in an uncontrolled manner causing the block to hit the lower walkway (grating) around the crane pedestal. The crane operator aborted the operation, called the deck foreman, and parked the crane in the boom rest. He stepped out from the cabin and started inspecting the walkway around the pedestal, looking for damage to the handrails after the crane block had struck.

It was during this inspection that he stepped onto the loose piece of grating and fell through.

What went wrong? What were the causes?

- The grating was loose and fell:

- The securing clips came loose as a result of the impact of the swinging crane block, and the loose grating was then dislodged.

- This piece of grating was fixed to the walkway structural frame in only two places.

- There was a kick plate welded onto the grating and not on the structure as on other cranes.

- The piece of grating had not been identified as potential dropped object.

- The securing clips came loose as a result of the impact of the swinging crane block, and the loose grating was then dislodged.

- The crane was boomed up above the limit, and the crane operator did not deal properly with this.

- Changes had occurred which were not properly managed or controlled.

- The crane operator inspected the walkway looking at the guardrails, not the grating.

What lessons were learnt? What actions were taken?

- Safety stand down held with all crew; grating replaced and secured.

- Engineering improvement of walkway design to be made, to prevent recurrence.

- Improvement of training for crane operators and lifting teams, particularly with regard to:

- emergency procedures

- handling unusual scenarios

- management of change (MOC)/risk assessments/toolbox or pre-Job meetings.

- emergency procedures

Related safety flashes

-

IMCA SF 23/16

13 September 2016

-

IMCA SF 08/08

24 April 2008

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.