Injury sustained during manual handling of sharp object

- Safety Flash

- Published on 9 November 2018

- Generated on 22 January 2026

- IMCA SF 25/18

- 2 minute read

Jump to:

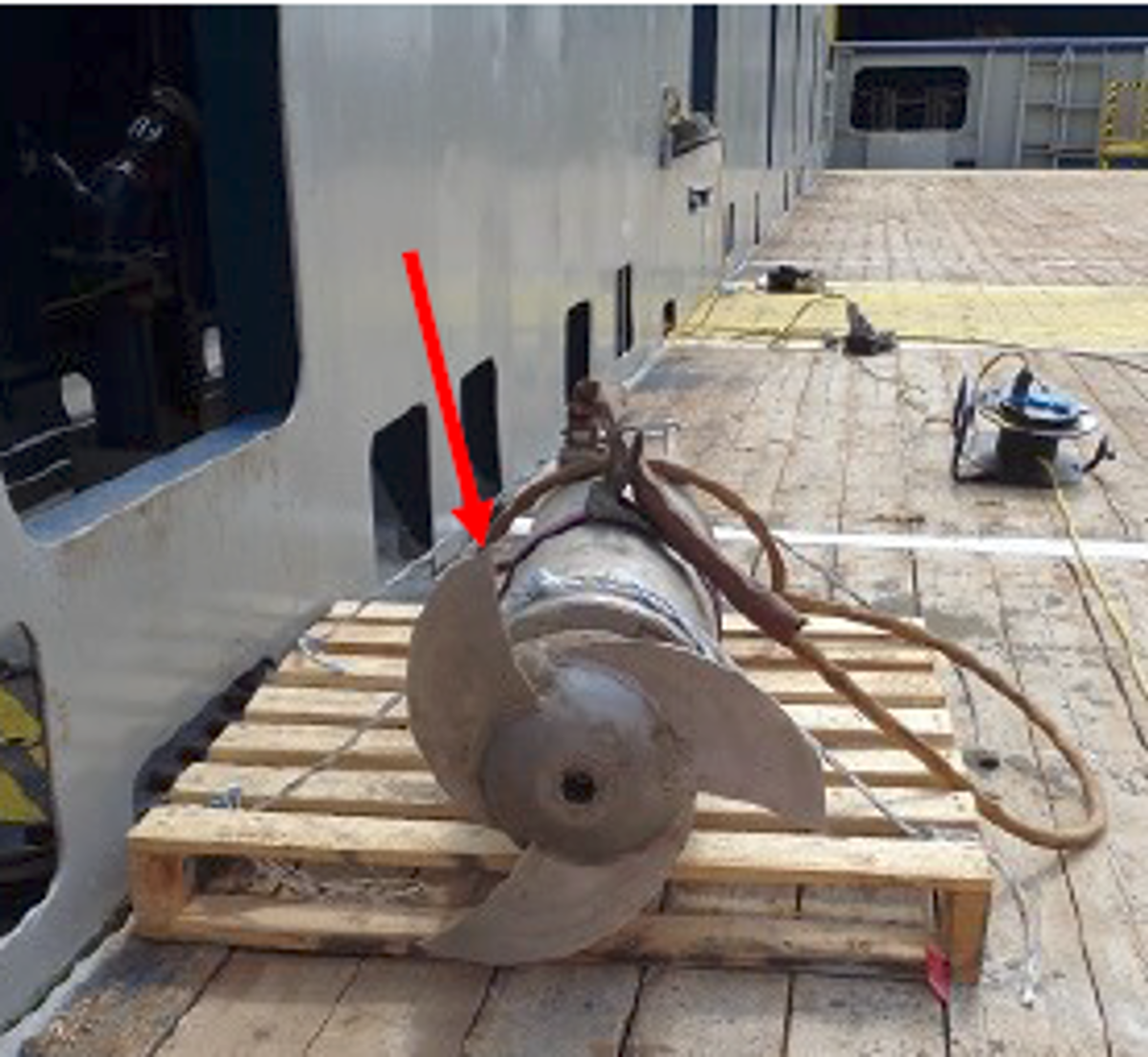

A crew member injured his leg while moving a mud agitator with unprotected blades.

What happened?

At the time of incident, the vessel was proceeding to port. First aid was administered immediately on-board, followed by further examination and treatment of the wound at a clinic onshore. The injured person returned to the vessel on the same day.

What went wrong? What were the causes?

- There was inadequate risk awareness – risks could have been reduced by protecting the blades before lifting/handling the agitator; waiting until the vessel reached port could also have reduced manual handling risks.

- Manual handling practice could have been improved – while the agitator was suspended by chain blocks during the work, whilst gripping the blades using pieces of rags (rather than wearing gloves), the load slipped from his hands and hit the crew members’ leg. A rope or another hands-off approach could have been used to turn/move/stabilise the load.

What actions were taken? What lessons were learned?

- Better risk awareness when moving objects with blades or sharp edges:

- protect the sharp edges

- arrange lifting and moving of load without actual manual handling – ropes, tag lines etc

- wait until more personnel are available and/or vessel is in port (as appropriate)

- use proper personal protective equipment (PPE) – gloves.

Members may wish to refer:

- Watch your hands [‘Be prepared to work safely’ video]

Related Safety Flashes

-

IMCA SF 28/16

18 October 2016

-

IMCA SF 07/12

10 July 2012

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.