Near miss: unplanned deployment of PLET outrigger

- Safety Flash

- Published on 9 November 2018

- Generated on 22 February 2026

- IMCA SF 25/18

- 2 minute read

Jump to:

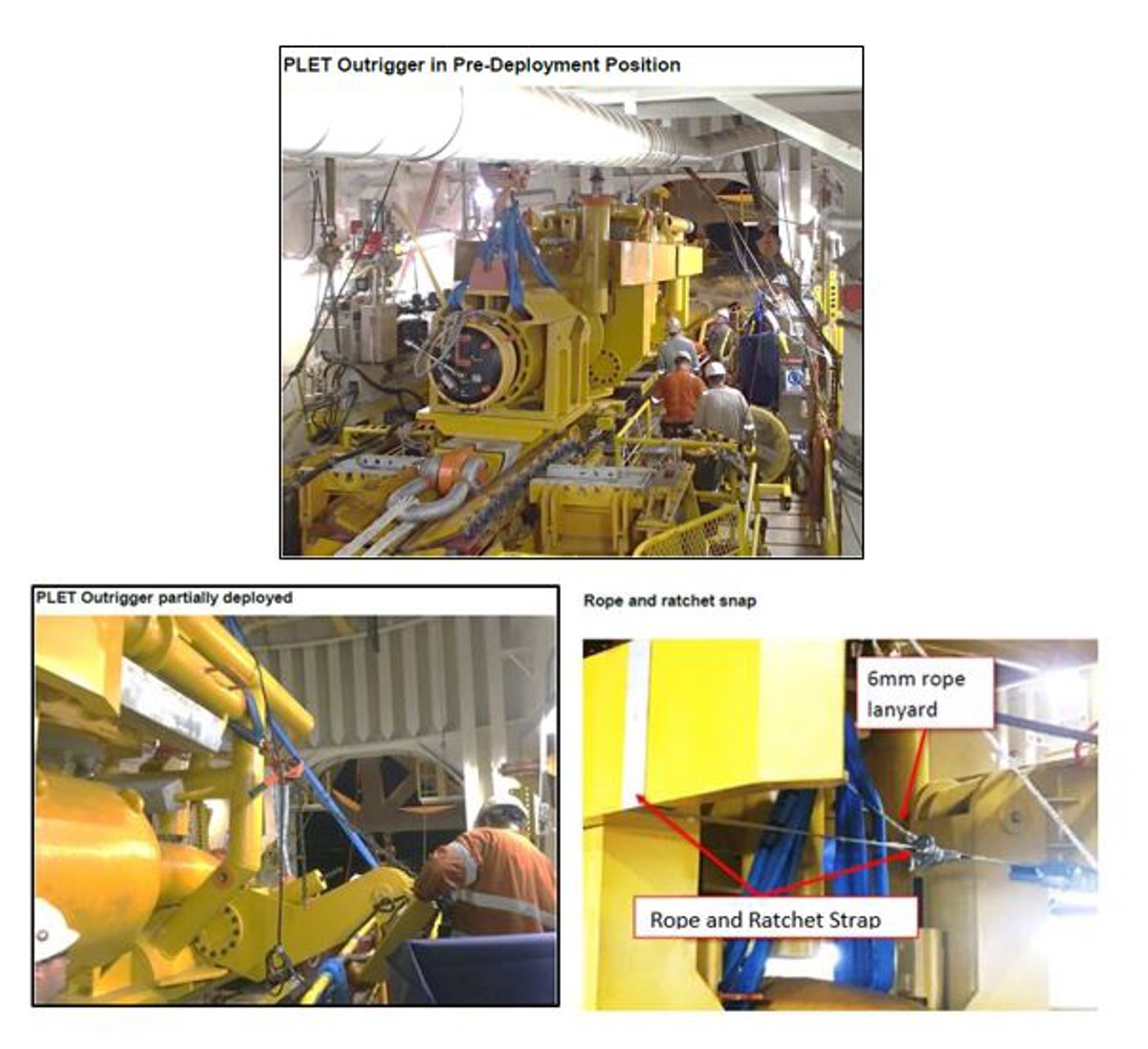

As a pipeline end termination (PLET) passed through the firing line, a rigger incorrectly cut a webbed ratchet strap (instead of a 6mm rope lanyard) which was restraining the aft PLET outriggers/stabilizer legs in the upright position.

What happened?

After cutting the ratchet strap, the starboard stabilizer leg deployed to approximately 35 degrees from vertical, coming to rest on the pipeline induction heat (PIH), injection moulded poly propylene (IMPP) unit. The port side outrigger released (approximately 60 degrees from vertical) until it came to rest on a nearby handrail.

What went wrong? What were the causes?

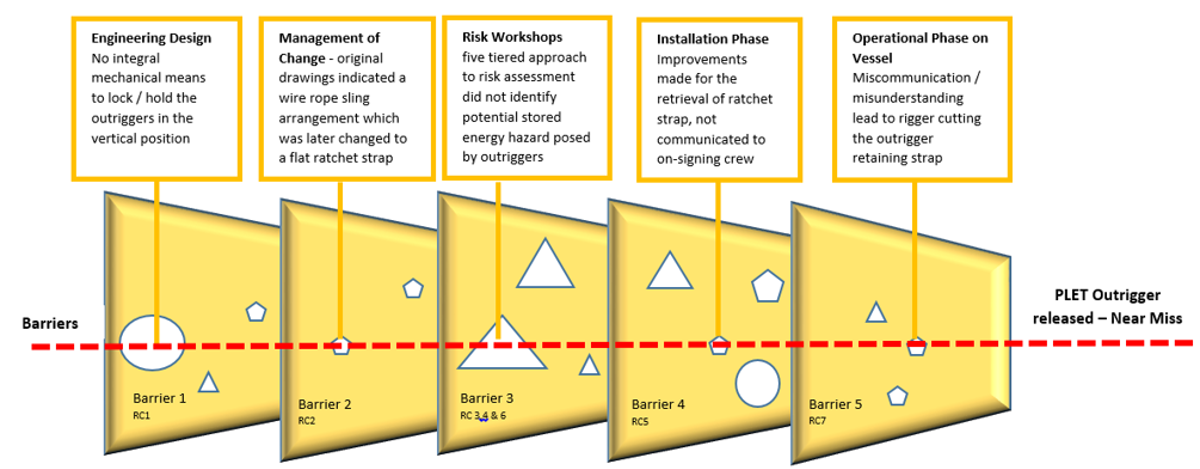

- Engineering design: there was no integral mechanical means to lock or hold the outriggers in the vertical position.

- Management of change (MoC): original drawings indicated a wire rope sling arrangement which was later changed to a flat ratchet strap.

- A risk assessment did not identify the potential stored energy hazard posed by the outriggers.

- Communication: a decision was made to introduce 6mm rope to the ratchet strap to allow for easy retrieval subsea with an ROV. This decision was made informally and intermittently conveyed between teams (field engineers and rigging), which introduced a new risk.

What actions were taken? What lessons were learned?

- Reviewed risk management process for the design of subsea structures to make the process more robust and to allow the project team to analyse structure designs and address all failure points during the design phase.

- Ensure changes to designs as supplied by a customer are managed robustly with justification documented for any engineered changes in rigging arrangements – a more robust MoC.

- Thorough review of risk management processes, particularly between teams and in the ‘interface’ between teams; in this case, between the fabrication and project teams.

- Reinforced the importance of clear communication during critical operations, to ensure the message/work scope is delivered in a clear manner and that any risks are fully understood by the crews.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.