Failure of in-service saturation bailout bottle

- Safety Flash

- Published on 22 September 2021

- Generated on 23 February 2026

- IMCA SF 26/21

- 2 minute read

Jump to:

What happened?

During saturation diving operations, Diver 1 reported his bailout bottle pressure dropped. A leak was observed by diver 2 but the origin was uncertain. Diver 1 returned to the bell and changed his bailout bottle. The leaking bailout bottle was removed in the bell trunking and stored in the clump weight basket.

Upon recovery to deck, the bailout bottle was found to have 3 pin holes on the side wall hidden by a locking clasp. Saturation diving operations were suspended and all bailout bottles from the same manufacture of the same type were taken out of service and quarantined.

leaking cylinder

internal surface of cylinder, showing corrosion over entire surface; leak location circled

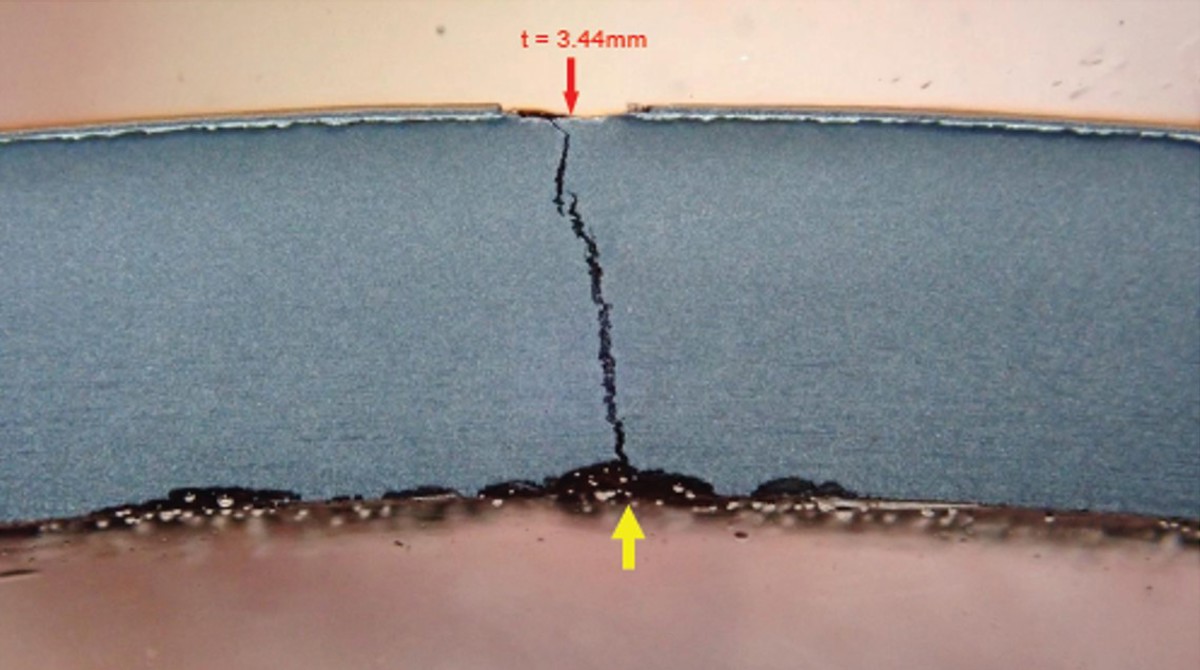

Cross-section through cylinder wall at the leak location showing a through-thickness crack; the cylinder suffered internal corrosion at the crack location, with a measured remaining wall thickness of 3.44 mm

What went wrong?

A through-wall defect 42mm long approx. was observed, with 3 small leak paths.

What were the causes of the incident?

- The primary factor was water/moisture on the internal surface of the cylinder, promoting corrosion. High levels of chlorides and possibly produced hydrogen may have led to the Stress Corrosion Cracking (SCC) and/or Hydrogen Stress Cracking (HSC) mechanisms.

- The root cause was suspected to be third-party testing and/or unsuitable long-term storage.

Lessons learned

- Improvement required for technical specification for servicing, testing and inspection of bailout bottles.

- Drying procedure used by supplier deemed to be inadequate.

- Bottle receipt and storage process deemed inadequate – potentially exacerbating internal corrosion.

Actions

- Verify that third-party procedures are fit for purpose and followed.

- Improve receipt inspection and storage of bailout bottles to ensure they are dried and sealed.

Members may wish to refer to:

Related Safety Flashes

-

IMCA SF 21/21

30 July 2021

-

IMCA SF 20/17

11 August 2017

-

IMCA SF 08/13

21 May 2013

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.