UK HSE: Employee scalped when hair trapped in a pillar drill

- Safety Flash

- Published on 22 September 2021

- Generated on 7 March 2026

- IMCA SF 26/21

- 1 minute read

Jump to:

What happened?

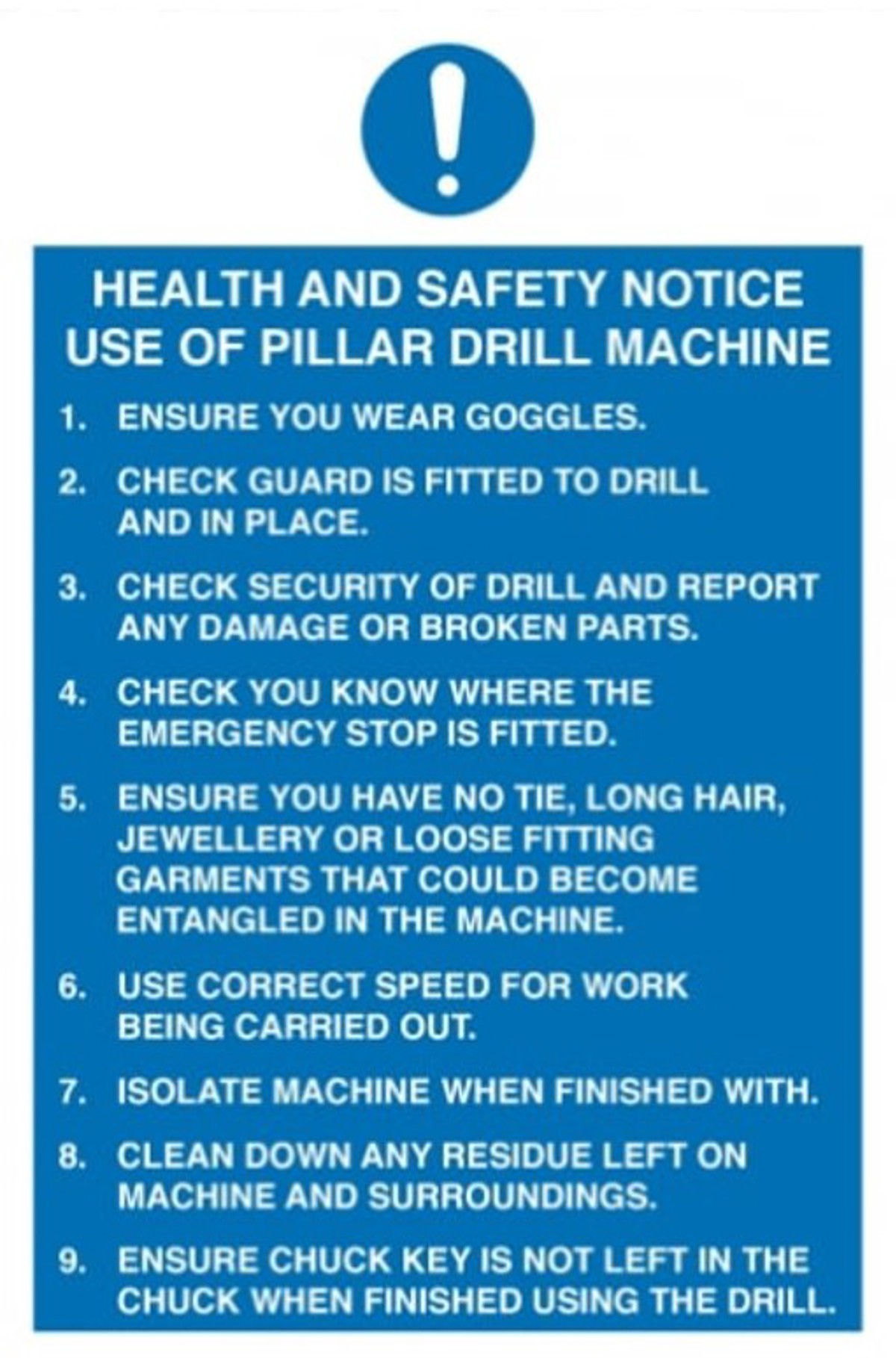

The UK Health and Safety Executive (HSE) has fined a company after an employee received scalping injuries when her hair became entangled in a pillar drill. Press release here.

An employee got her hair caught in a rotating pillar drill and as a result suffered life changing injuries when her scalp and part of her ear were torn off.

What went wrong?

Investigation revealed that:

- The rotating parts of the drill were not guarded in accordance with standard industry practice.

- The company’s own risk assessment for using the drill had identified that a guard should be fitted, but evidence obtained indicated the drill had been operated without one for several years.

IMCA members have reported a number of incidents where employees have suffered injuries from pillar drills or from other rotating machinery.

This is an area where a fresh focus may be productive in improving safety.

Related Safety Flashes

-

IMCA SF 04/21

2 February 2021

-

-

IMCA SF 14/19

18 June 2019

-

-

IMCA SF 02/19

13 February 2019

-

-

IMCA SF 28/18

18 December 2018

-

-

IMCA SF 22/18

25 September 2018

-

-

IMCA SF 32/17

21 December 2017

-

-

IMCA SF 28/17

7 November 2017

-

-

IMCA SF 19/17

2 August 2017

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.