Raising awareness on safety barriers such as railings and gratings

- Safety Flash

- Published on 6 December 2019

- Generated on 1 March 2026

- IMCA SF 28/19

- 3 minute read

Jump to:

The Transport Safety Investigation Bureau (TSIB) of Singapore has released Safety Flyer 2019/02 entitled The importance of ensuring proper inspection and maintenance regime.

What happened?

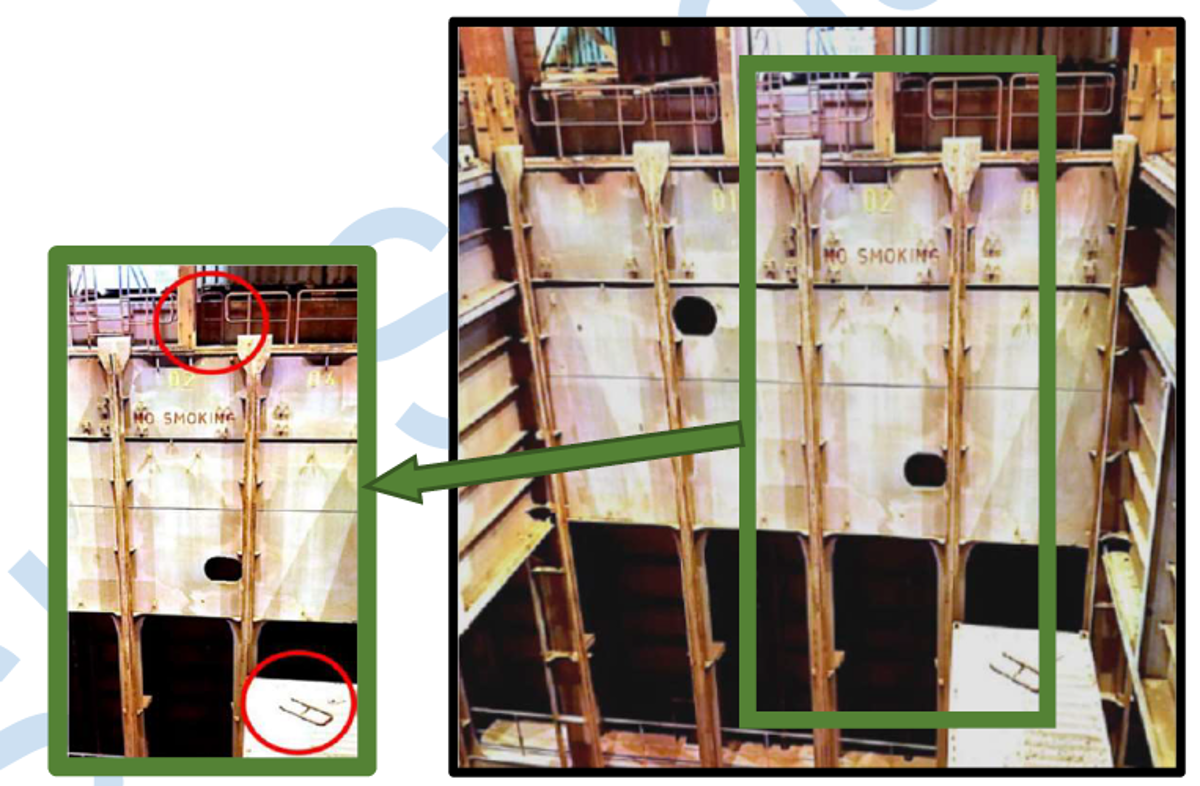

The safety flyer is intended to raise awareness on the importance of carrying out comprehensive inspection of safety barriers such as railings and gratings, and to encourage timely preventive maintenance and implementation of adequate safeguards in place to ensure safety of personnel on board ships.

What went wrong? Some recent occurrences

- A stevedore was fatally injured by falling into the cargo hold of a container ship; investigation revealed that a safety railing, which was in poor condition and badly corroded, could have contributed to the fall of the stevedore from a height of about 20 metres. Although the corroded safety railing had been identified to be one of the tasks to be carried out on-board, there were no safeguards or warning signs put in place to warn personnel in the vicinity of its condition.

- A crew member of a container ship had a fatal fall from a height of almost 20 metres, when the base plate of the crane cabin he had just entered gave way, and he died at the hospital.

Corrosion fatigue on-board ships?

The TSIB notes the following:

- Most forms of corrosion on-board ships occurs due to oxidation, which implies the presence of oxygen or oxidisers, for the metallic reaction to form rust.

- Atmospheric conditions at sea typically accelerates this corrosion and the severity is commonly caused by airborne (sea) salt spray, temperature and moisture. Generally, moisture when combined with elevated temperatures and salt, intensifies the corrosion process.

- In spite of the requirement for steel to be galvanised when used for shipbuilding, comprehensive preventive measures for inspections and maintenance form the crucial safeguard against deterioration of the metal’s strength and thickness integrity.

Actions

The TSIB recommended the following practices:

- A comprehensive inspection regime of areas which could pose a threat to the safety of personnel should be in place so as to facilitate appropriate intervention and priority for carrying out appropriate repairs in a timely manner.

- Safety barriers/gratings are meant to protect personnel from potential hazards, such as prevention of falling from height. Where safety barriers/gratings are found to be corroded such that their main role of providing functions could be compromised and pose a threat to personnel, shipboard staff should take appropriate mitigating measures by putting up warning signs and cordoning off such areas to the extent practicable and make such observations known to the company.

- Inspections of areas which are covered by anti-slip mats or any other similar concealments of metallic surfaces, should be carried out in detail especially where the chance of moisture being trapped is high.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.