UK MAIB: Electrician injured in explosion

- Safety Flash

- Published on 6 December 2023

- Generated on 18 July 2025

- IMCA SF 28/23

- 3 minute read

Jump to:

The UK Marine Accident Investigation Branch (MAIB) has published Safety Digest 2/2023, consisting of lessons from recent Marine Accident Reports. IMCA has reviewed the report and passes on to Members, as some of the incidents in the MAIB report will be of interest. This is one of them.

What happened?

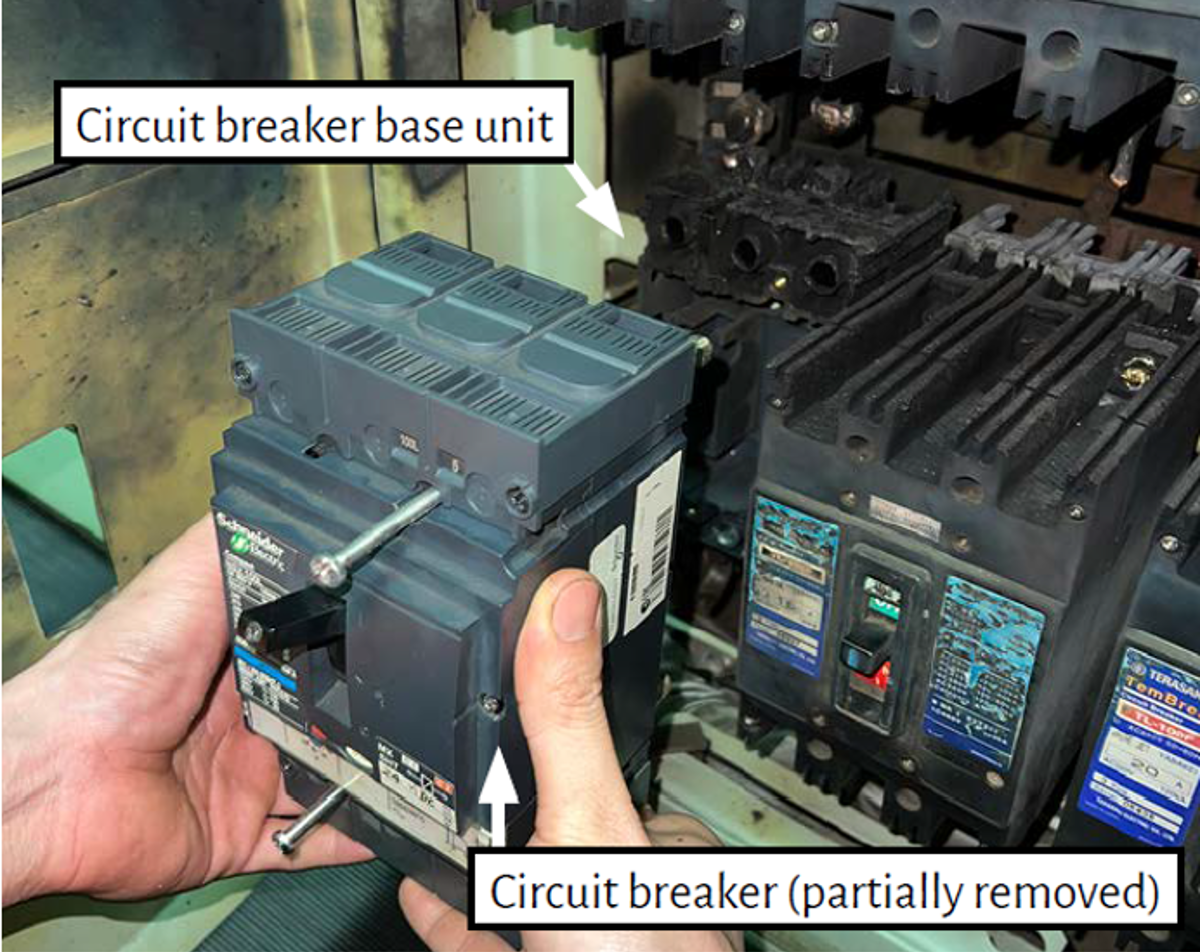

An electrician was badly injured while working on a switchboard. The circuit breaker was designed to be removed without the need to isolate the base unit (Figure 1).

Fig. 1: The circuit breaker arrangement

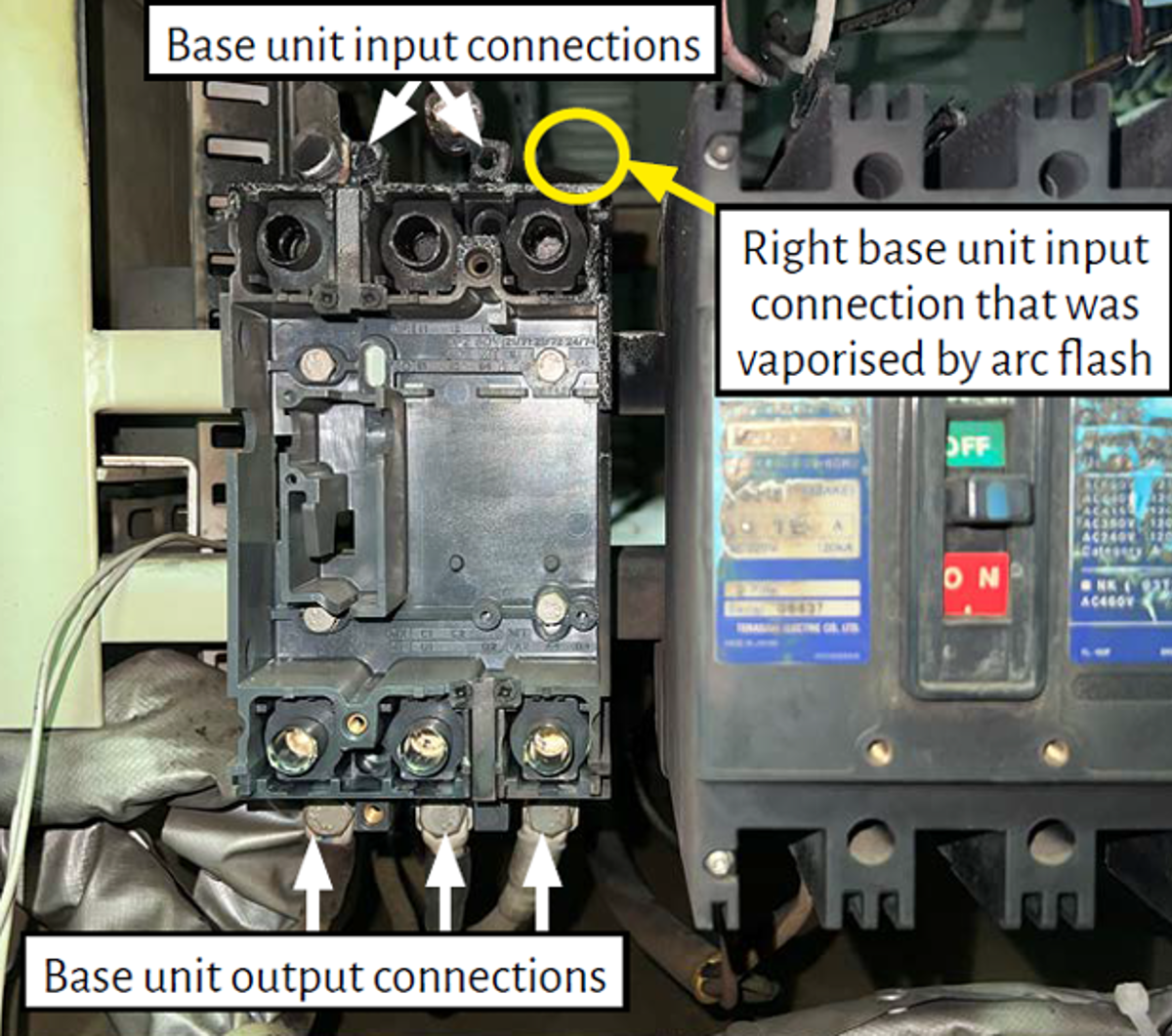

However, the electrician was unfamiliar with this arrangement and had loosened one of the live connections on the input to the base unit (Figure 2).

Fig. 2: The base unit connections

The electrician used rubber gloves to insulate himself from the live 440 V alternating current terminals when working on the connections.

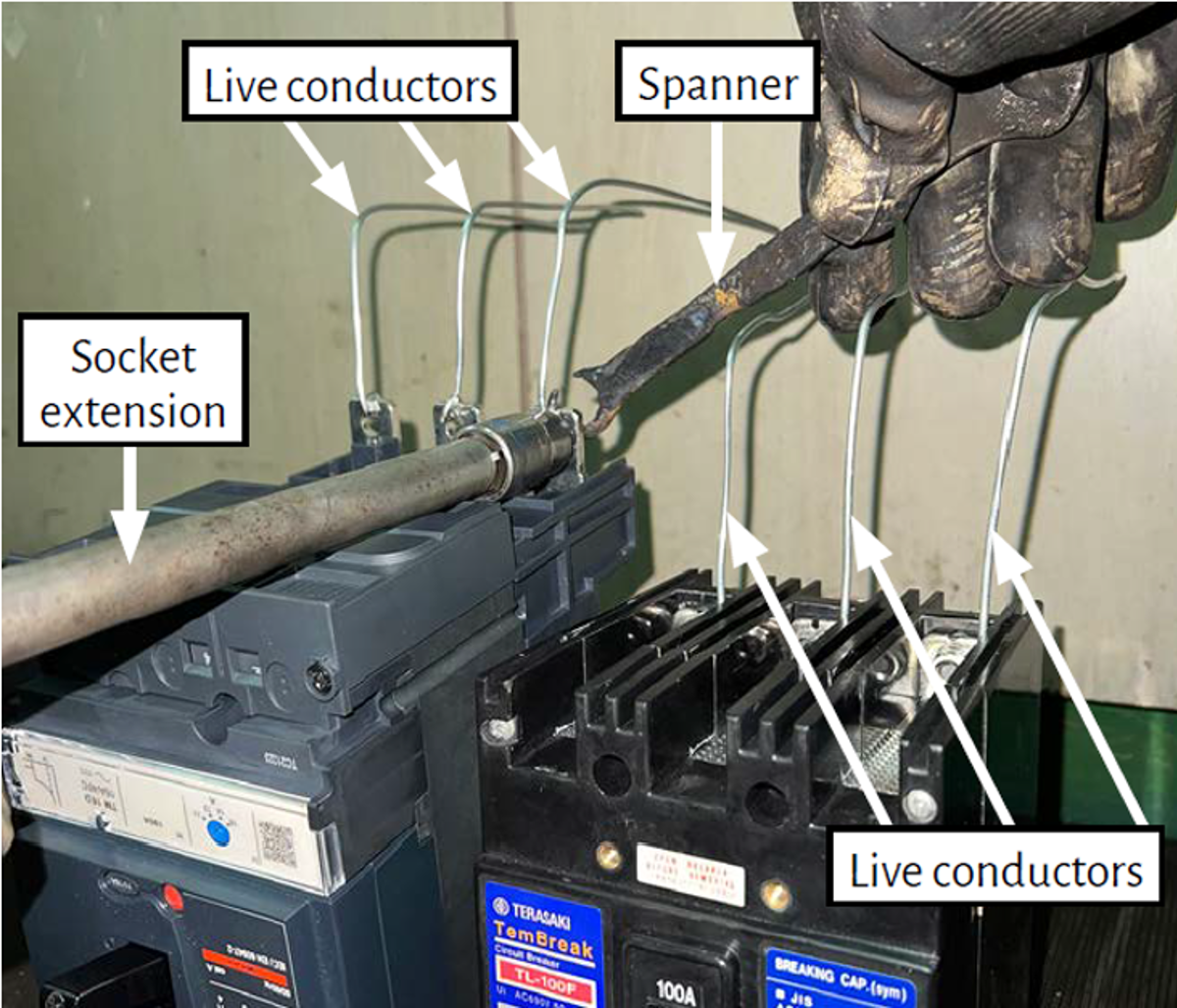

The electrician tried to reconnect the cables to the base unit using a socket extension on the head of the bolt and a spanner to hold the nut in position at the rear of the connections.

As the electrician tightened the bolt on the live input connection, the nut rotated and the steel spanner touched an uninsulated copper conductor on the adjacent circuit breaker base unit.

This caused a short‑circuit between two phases of the switchboard (Figure 3).

Fig. 3: Reconstruction of the accident

The short-circuit caused a high current to flow, vaporising the copper conductor and part of the spanner in an arc flash creating extreme heat and blinding light.

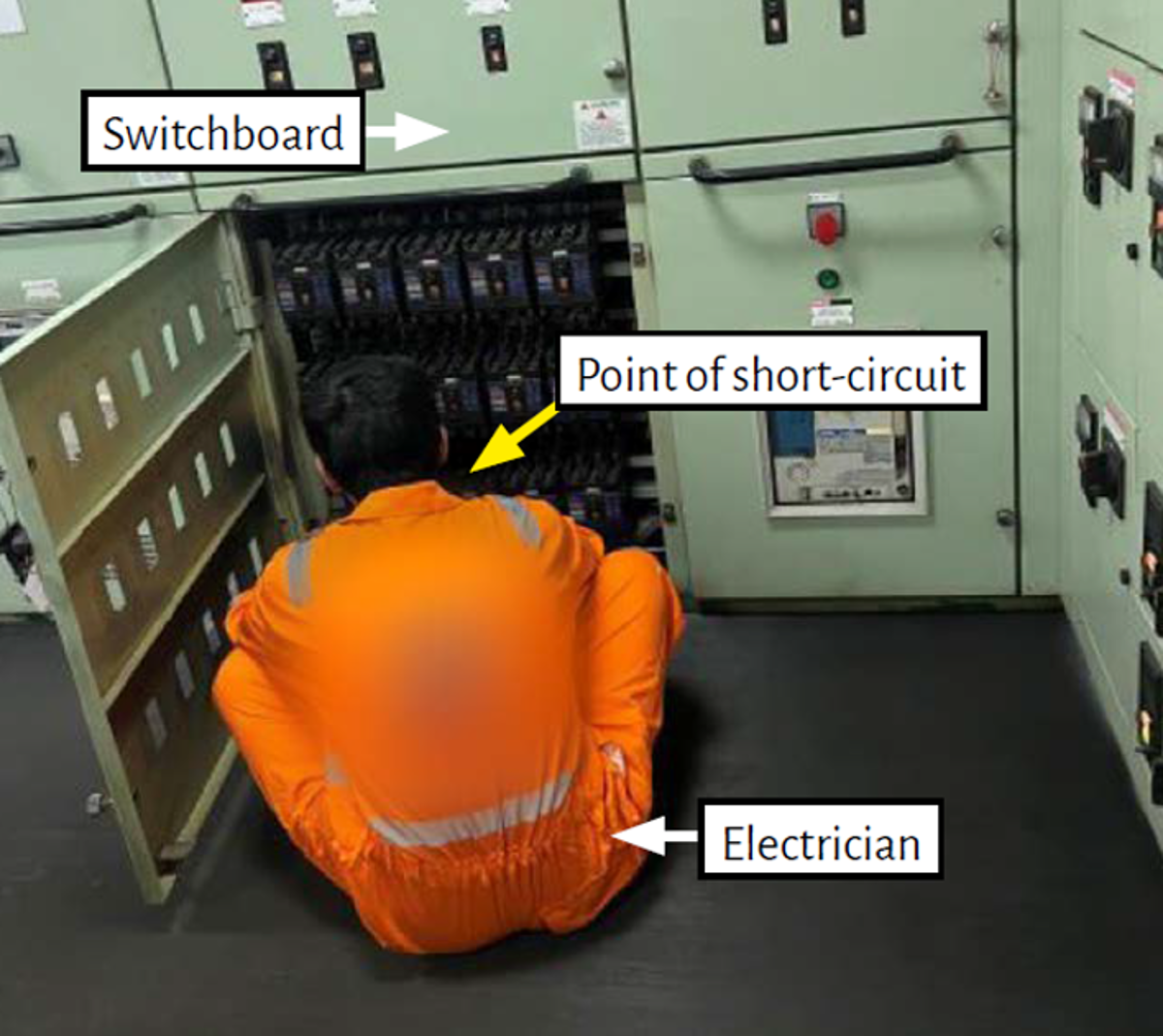

A burst of hot gas and molten metal exploded from the panel onto the electrician’s face and chest (Figure 4).

Fig. 4: Position of the electrician

The ship’s engineers were alerted to a problem with the switchboard when the remote machinery alarm system sounded in the mess room.

As the engineers headed to the engine room, the Electrician arrived on the ship’s bridge with serious burns to the face and chest.

The following day, the electrician was transferred to hospital for medical treatment and later sent home.

There was significant damage to the ship’s main switchboard.

What went wrong?

- The electrician twice disobeyed clear instructions from the chief engineer, to not work in the switchboard.

- The electrician was not familiar with the arrangements within the switchboard – had he taken the time to fully understand the arrangement of the circuit breaker and base unit assembly, that would have enabled the electrician to safely remove the circuit breaker and reduce the risk.

- The electrician was working alone without a Permit to Work, lock-out/tag-out arrangement or a safe system of work. The work was unexpected and therefore not included in the day’s planning meeting. New work requires a new plan, regardless of time pressures.

- Working near live electrical equipment requires specific tools and PPE. The use of uninsulated tools while working in a live switchboard invited a short-circuit and the electrician, who was not wearing face protection, was lucky not to lose his eyesight.

Related safety flashes

-

IMCA SF 26/21

22 September 2021

-

-

IMCA SF 06/20

19 February 2020

-

-

IMCA SF 18/14

25 November 2014

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.