Crane malfunction during lifting operations

- Safety Flash

- Published on 24 October 2016

- Generated on 2 March 2026

- IMCA SF 29/16

- 2 minute read

Jump to:

A Member has reported an incident in which there was a crane failure during lifting operations.

What happened?

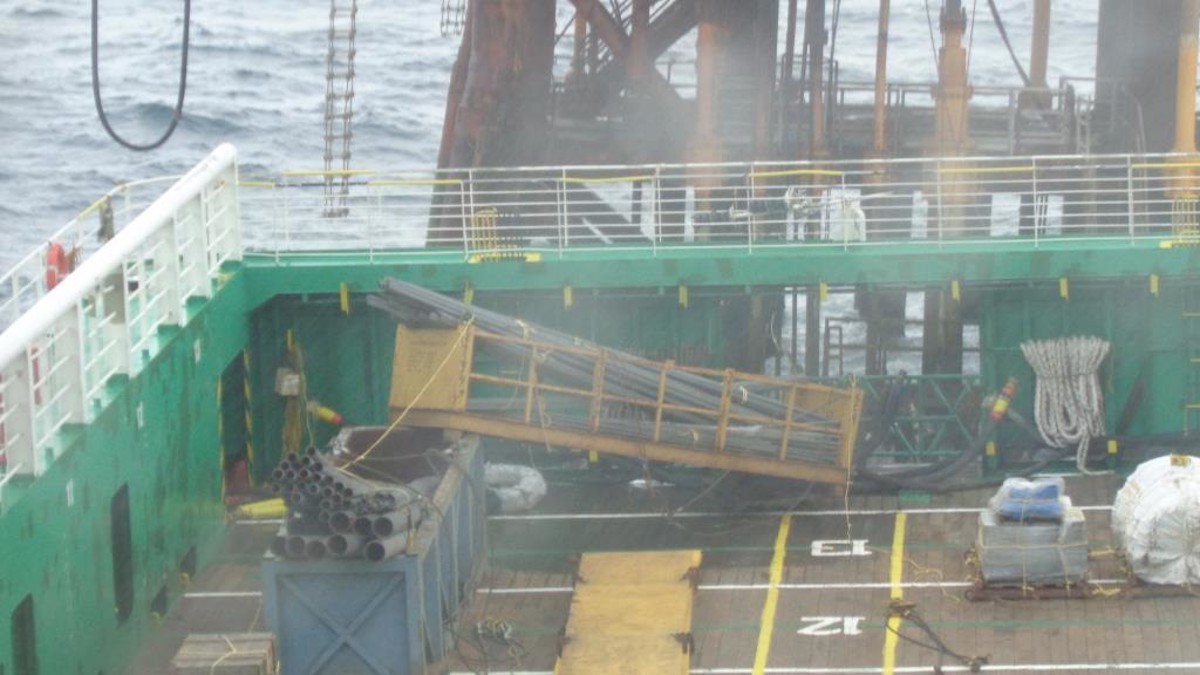

The incident occurred when a platform supply vessel (PSV) was working with a platform crane. The crane lifted the basket (filled with 5m pipes) to crash rail level, but couldn’t manage to take it further. The crane got stuck in hoist mode for a moment and later the hook with the tilted basket landed and rested on top of another basket.

The crew, who were holding the tag line, moved swiftly to safety. After unhooking the lift and steadying the tilted basket with wedges, the PSV retreated from the 500m zone. Later the PSV came back in and the platform crane was used to establish the basket properly on deck.

Our member’s investigation revealed the following and corrective action was taken:

- There was an equipment malfunction on the platform crane.

- The Master immediately informed the crane operator to place the basket back on deck and arranged for it to be secured.

Our member noted the following:

- It is important that the correct load is mentioned on the cargo manifest at the time of loading the cargo at base.

- The platform crane should be properly maintained and able lift the cargo manifested for it.

Related Safety Flashes

-

IMCA SF 05/15

2 April 2015

-

IMCA SF 11/05

30 November 2005

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.