Smouldering fire in tumble dryer

- Safety Flash

- Published on 26 November 2020

- Generated on 6 March 2026

- IMCA SF 32/20

- 2 minute read

Jump to:

What happened?

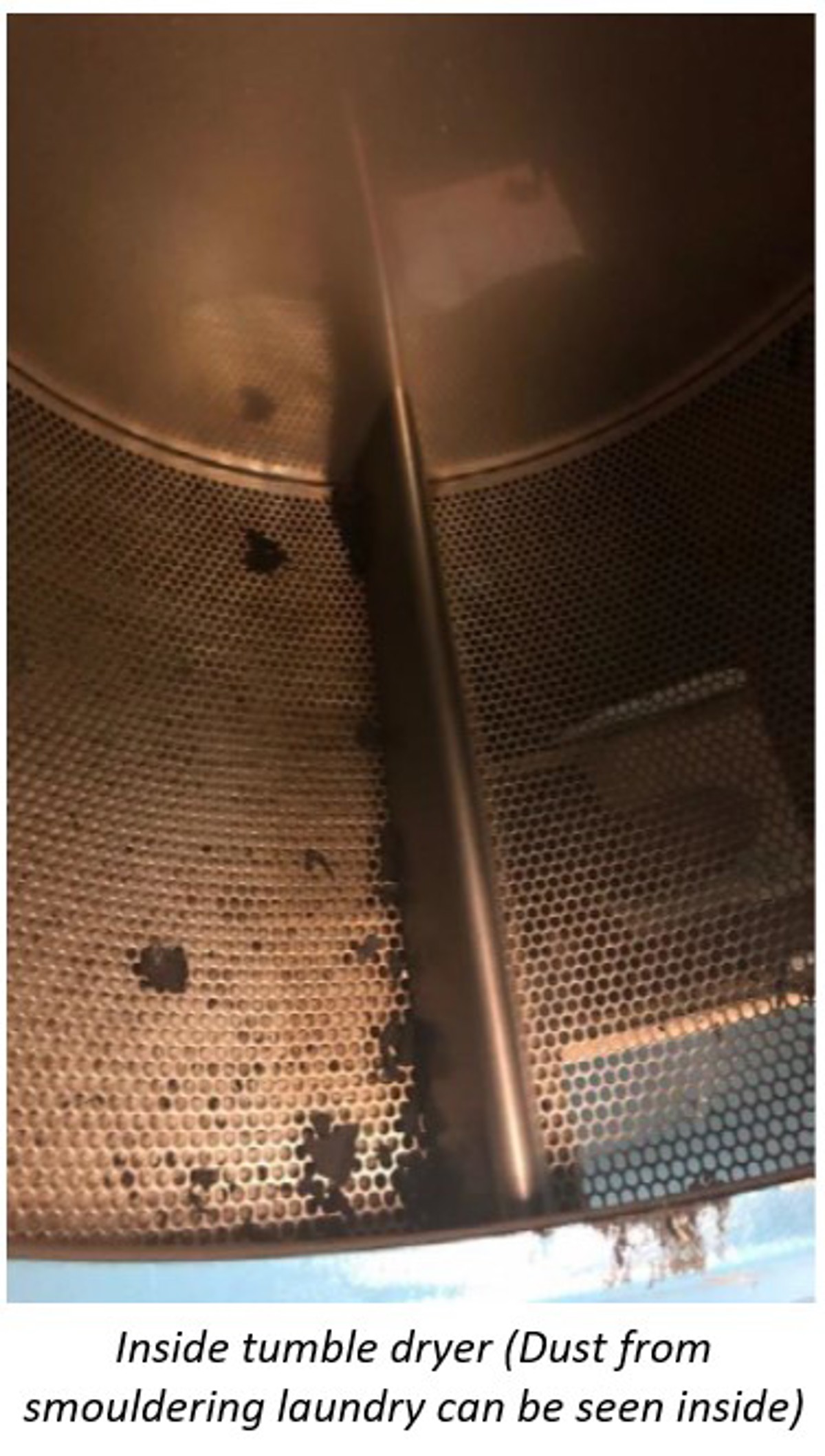

A tumble dryer was in operation when the heat within the machine exceeded its safe operating level resulting in items of laundry inside the machine overheating and generating smoke.

A crew member smelt smoke in the laundry and established it was coming from the tumble dryer. The tumble dryer was switched off and then opened and at which point the laundry items ignited due to the ingress of air.

The fire was quickly extinguished using a nearby fire extinguisher, the bridge was informed and a fire team mobilised to confirm the area was safe.

What went wrong?

The fire was due to a build-up of dust/residue inside the exhaust ducting between the tumble dryer and secondary filter, causing the safe operational limits of the machine to be exceeded.

Further investigation established that the heat sensor, a safety feature designed to protect the machine from overheating, had failed.

Actions

- Ensure that all tumble dryer filters and exhaust systems are regularly cleaned.

- Ensure that the design of the tumble dryer filters and exhaust ducting enable full access to the tumble dryer and exhaust ducting. Consider whether additional access hatches need to be installed to improve access.

- Check of the safety sensors within the tumble dryers and consider installation of a secondary safety sensor as back-up.

- Confirm that heat and smoke detection in laundry rooms is suitable and sufficient.

Members may wish to refer to

- Auto-ignition of laundry items

- Near miss: potential fire – overheating of oil in deep frying pan [issues with temperature sensor]

- Fire in incinerator exhaust gas manifold [issues with temperature sensor]

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.