Three bolts sheared on a lifting trunnion

- Safety Flash

- Published on 20 January 2022

- Generated on 13 July 2025

- IMCA SF 02/22

- 2 minute read

Jump to:

A hatch cover weighing 44kg fell approximately 0.5m after the securing screws had sheared.

What happened?

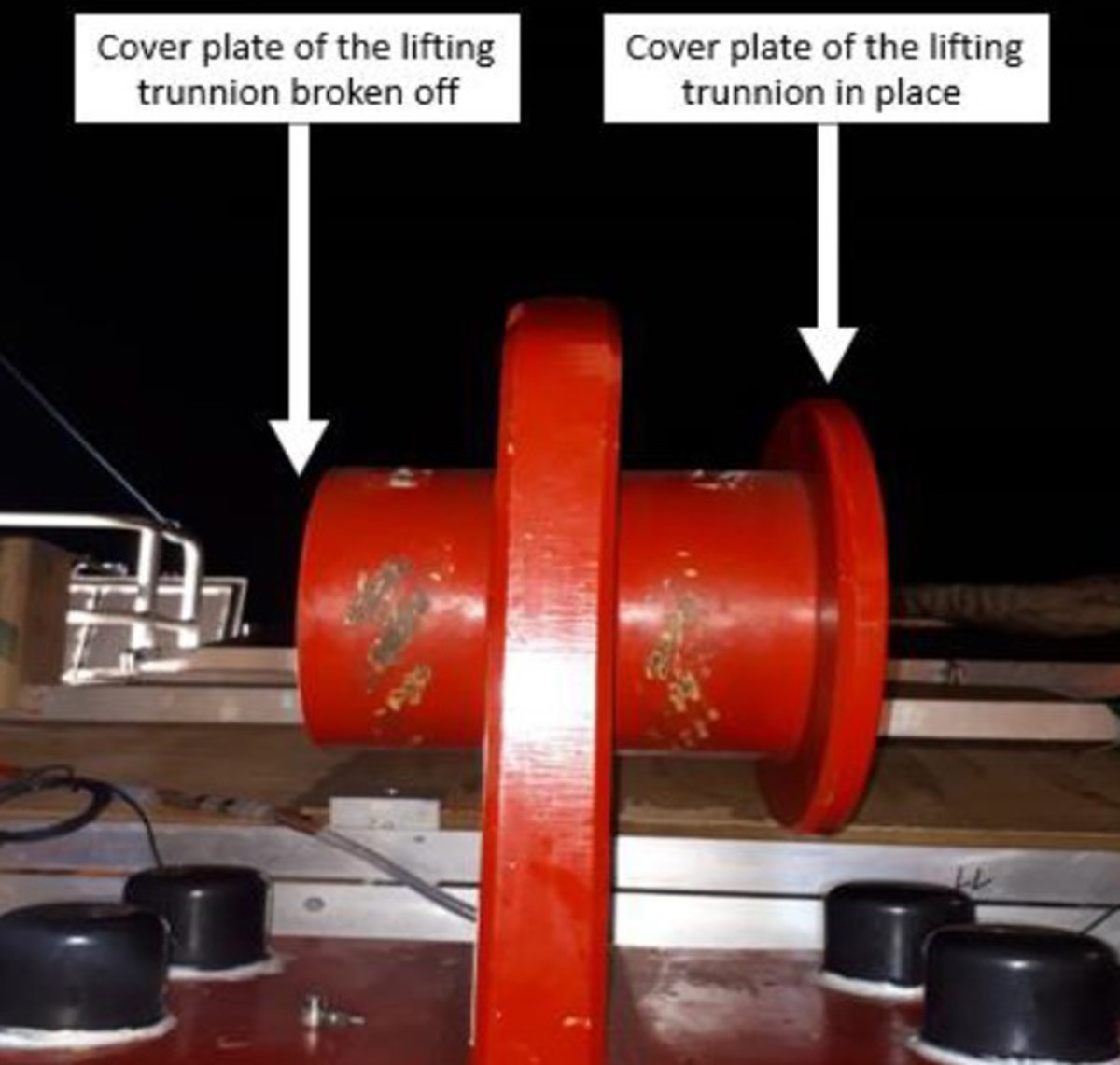

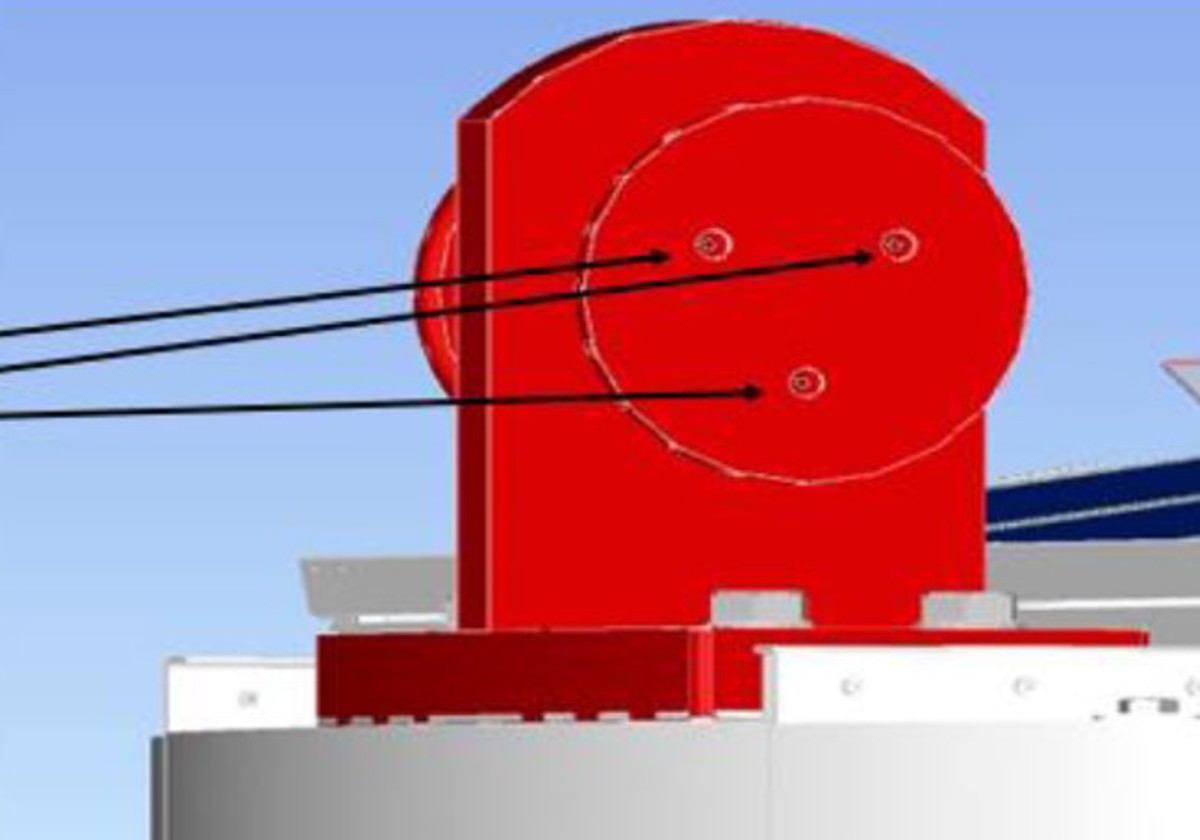

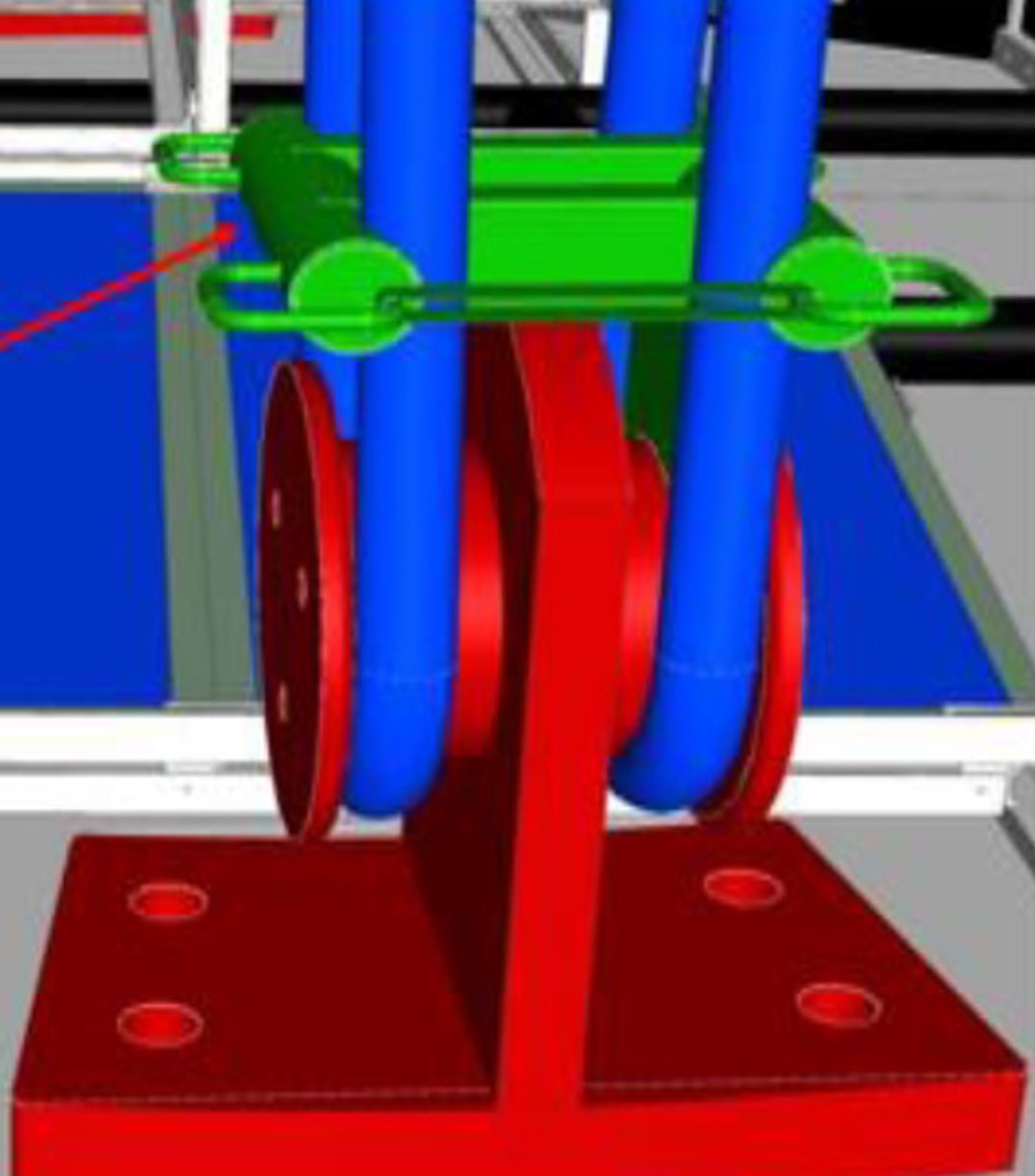

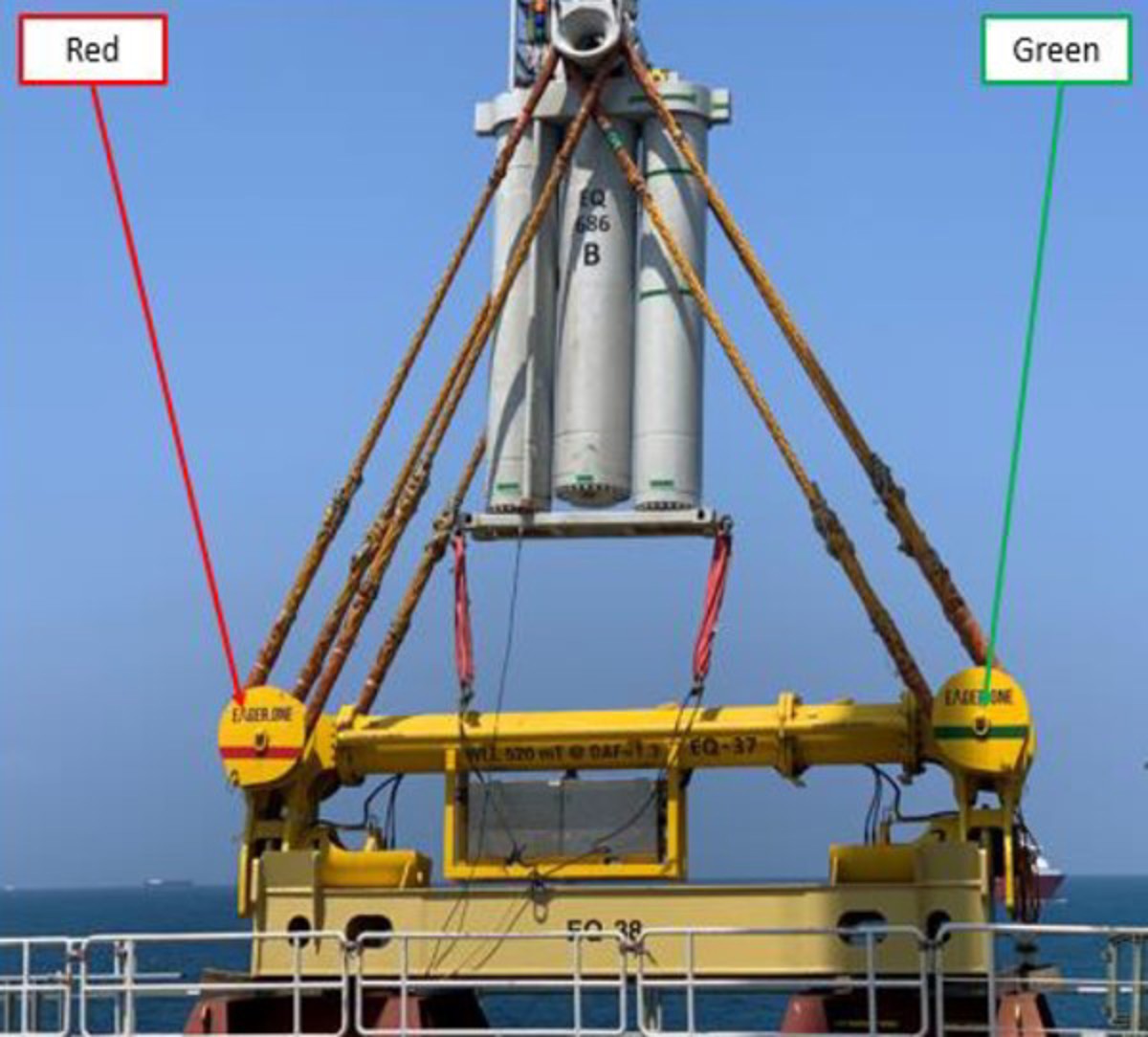

After successful installation of a offshore renewables Transition Piece (TP), crew accessed the TP and discovered that the cover plate of the lifting trunnion had fallen off and was on the hatch cover of the TP with its three securing screws close by. The securing screws had sheared. The cover plate weighed 44kg and fell approximately 0.5m from the lifting trunnion to the hatch cover.

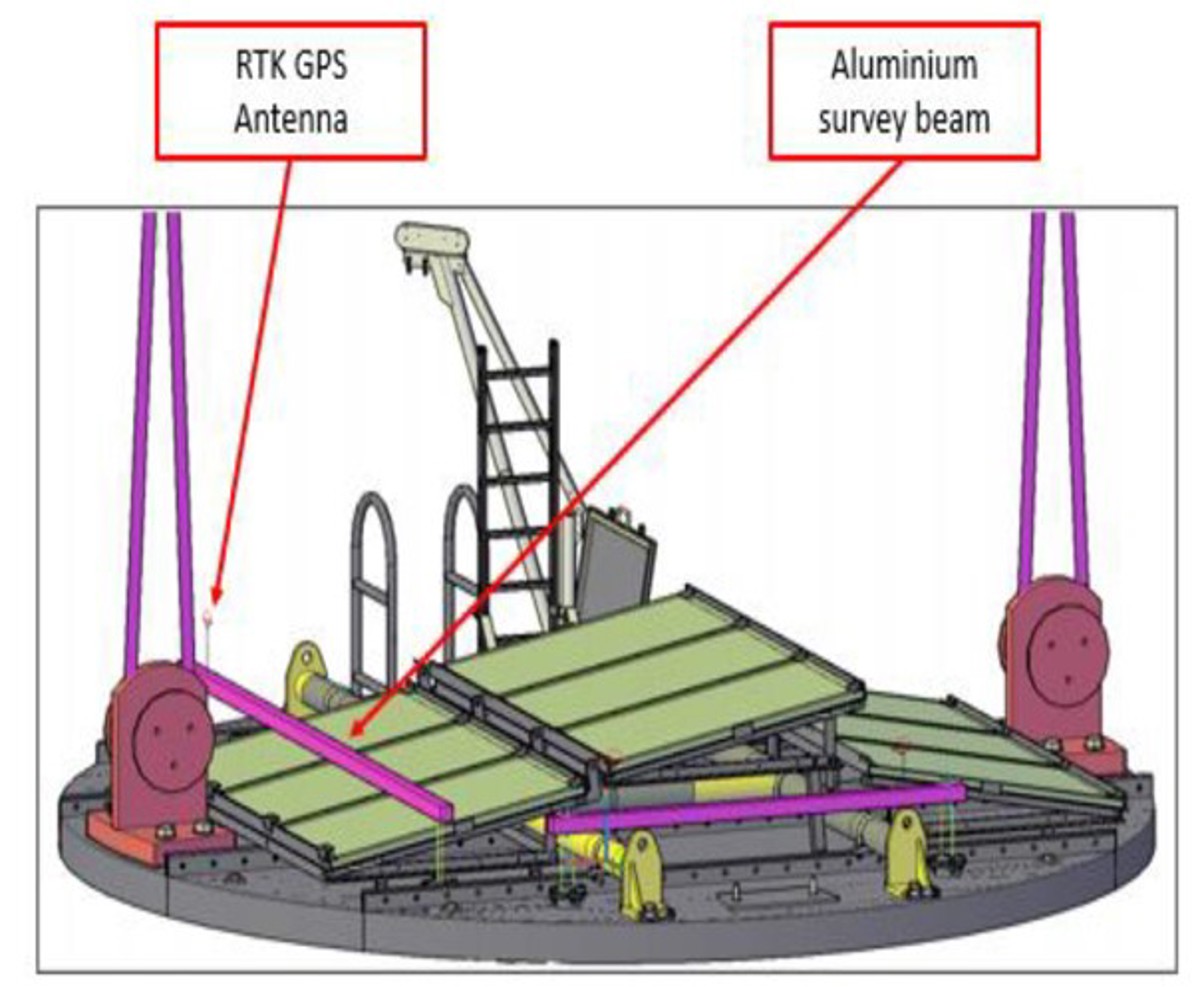

Further inspection followed and it was observed that there had been some damage to a survey beam and an antenna of GNSS positioning equipment. The damage caused to the antenna was fixed onboard. The survey lifting beam had to be replaced, but there was a spare onboard and a replacement beam was ordered.

What went wrong?

It was considered that the method of verifying the suitability of the screws attaching the cover plate to the lifting trunnions was incorrect. It was assumed that the sideway forces experienced by the cover plate were exactly introduced in the centre of the lug cover. However, this was not case. This assumption resulted in the inadequate method of securing the cover plate to the lifting trunnion.

What went right?

- A permit to work was in use for the task, a toolbox talk was held where the Job hazard analysis was referenced and a Last-minute risk assessment was used. The task plan was adhered to throughout the installation.

What were the causes?

- The side forces experienced by the cover plate were greater than the screws could withstand; this could have been foreseen. Our member considers the root cause to be human error.

Actions

- Weld the cover plates to the lifting trunnions.

Related Safety Flashes

-

IMCA SF 26/18

3 December 2018

-

-

IMCA SF 09/21

30 March 2021

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.