Inappropriate use of snap hooks

- Safety Flash

- Published on 27 January 2011

- Generated on 3 March 2026

- IMCA SF 01/11

- 2 minute read

Jump to:

A Member has reported that, in spite of efforts to prevent the practice, regular incidents involving the inappropriate use of hooks have continued to occur.

A number of incidents have been reported, including dropped objects, accidentally released buoyancy and near misses.

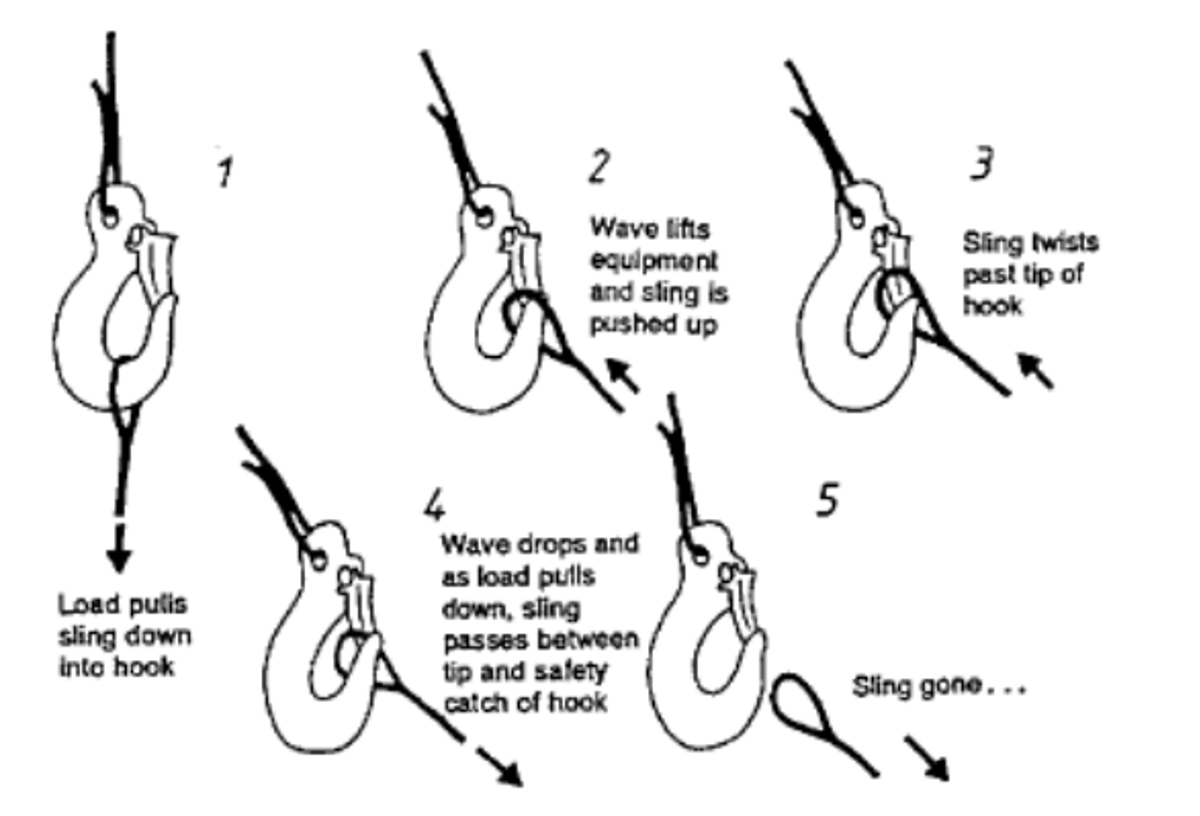

This issue concerns the use of snap hooks when handling or deploying loads instead of shackles or ‘safety’ type hooks with load capable latches. It is necessary to use these because some loads are capable of ‘floating’ during transition through the splash zone and/or during transit through the water column.

The most common incidents involve dropped objects. These occur because of the relationship between the surface area and mass of the object being lifted, combined with water resistance, as well other factors such as vessel movement and winch speed. When snap hooks are used in such circumstances, the gates or latches can be opened or broken by the rigging and the load is at risk of being dropped.

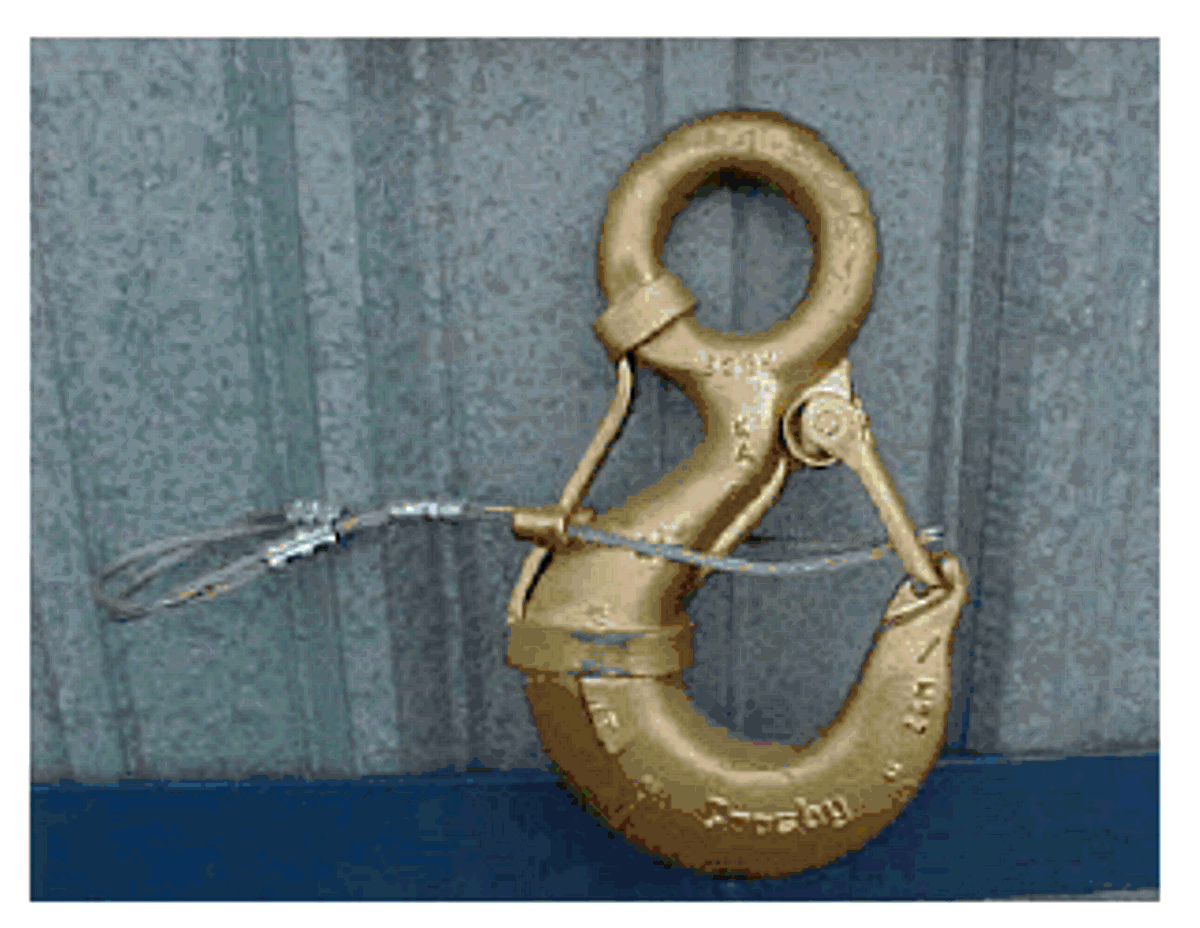

fig. 1: example of modern ROV-friendly safety hook designs

fig. 2: example of modern ROV-friendly safety hook designs

fig. 3: how loads can be lost from snap hooks

Lessons learnt

Our member made the following recommendations:

- All loads should be checked for the likelihood of this happening in line with existing industry-wide engineering and rigging good practice.

- Only suitably trained people should be used to select the appropriate rigging and sling loads for lifts.

- All non-engineered subsea load handling should use shackles or safety hooks rather than snap hooks.

- Snap hooks can be used for loads where there is no risk of the load becoming ‘light’ during the transit to/from deck. They should not be used unless the operation has been thoroughly checked and endorsed by competent personnel.

Our Member notes that suppliers have been approached to address the latch design issue and analyse potential strength upgrades. New safety hook designs that can be operated by an ROV operable are being evaluated.

Members may wish to refer to the IMCA document Guidelines for lifting operations for further information.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.