Serious hand injury during use of deck scaler

- Safety Flash

- Published on 25 February 2011

- Generated on 8 March 2026

- IMCA SF 02/11

- 2 minute read

Jump to:

A Member has reported an incident in which a crew member sustained a serious hand injury while using an air driven deck scaler during maintenance operations on deck.

What happened?

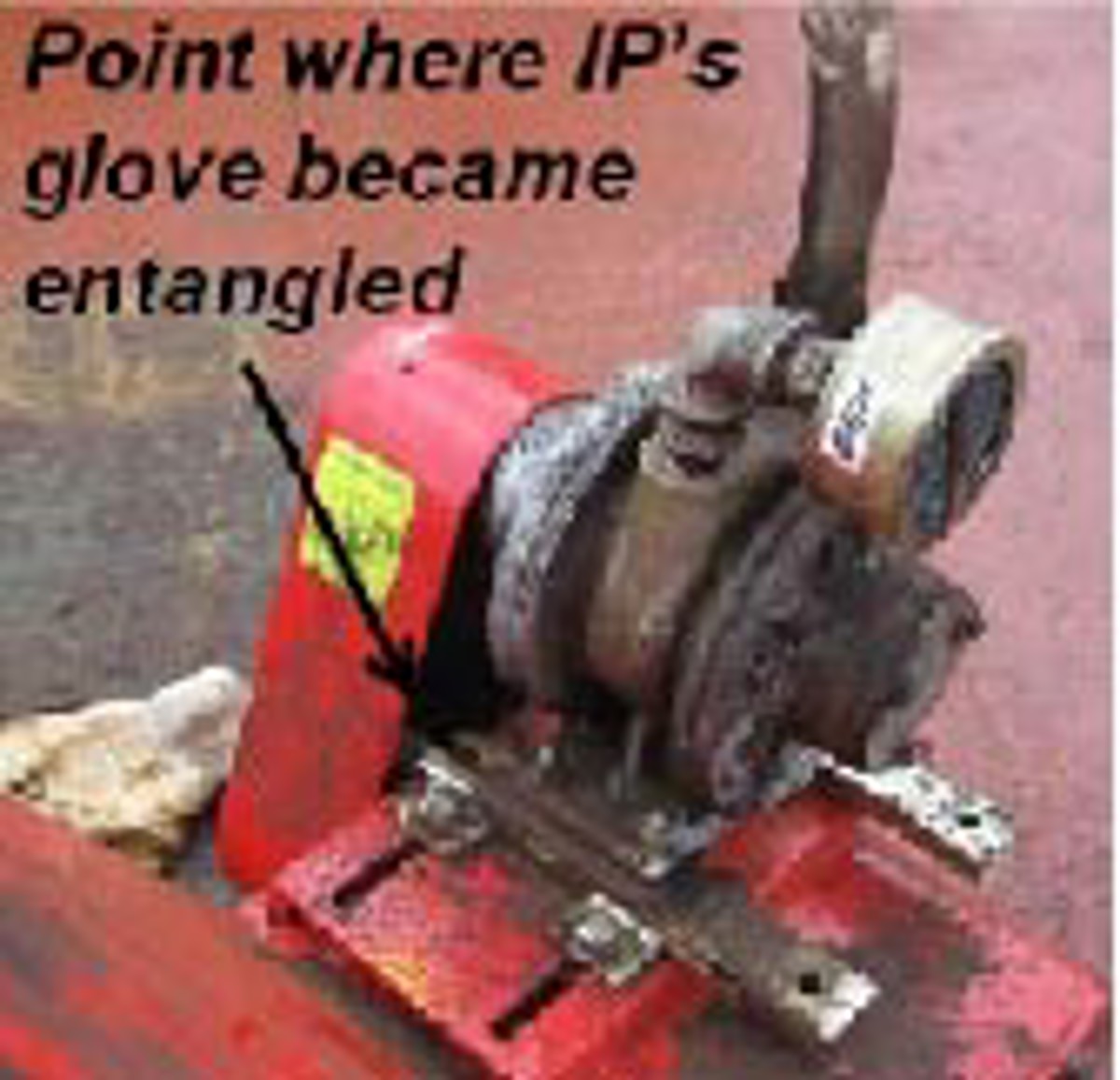

The crew member was wiping clean an area on the scaler to the rear of the motor when his glove became entangled in the drive belt and his fingers were subsequently trapped. The crewman sustained crush injuries to the tips of two fingers, and was medevaced for treatment and subsequent surgery. Fortunately no amputation resulted.

deck scaling machine

deck scaling machine showing where person’s glove was caught

What were the causes?

Investigation of the incident noted that:

- The deck scaling machine had no ‘dead man’ type control.

- The physical barrier to injury offered by the installed guards on the deck scaler was defeated.

- Existing company procedures for the use of this air-driven device clearly state ‘disconnect airline before any troubleshooting or maintenance’.

The incident highlighted:

- a design deficiency in the deck scaling machine

- a failure to follow basic safe working practices.

Actions

The following actions were implemented:

- Further use of machines of this type was prevented until the suitability of appropriate control measures could be demonstrated; these include:

- ‘hard’ barriers such as guarding and a dead man switch, and

- ‘soft’ barriers such as risk assessment and operating instructions.

- ‘hard’ barriers such as guarding and a dead man switch, and

- Further equipment was identified which may present a similar risk (guarding/dead man switch), i.e. drilling machines, lathes, bench grinders, etc. and actions identified which would appropriately manage the risk.

The manufacturer of the deck scaler was contacted to feedback concerns and highlight the lack of a ‘dead man’ switch on the device, and a swift and positive response was received from the manufacturer.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.