Near miss: Potential dropped object due to unsecured door.

- Safety Flash

- Published on 23 January 2018

- Generated on 26 February 2026

- IMCA SF 02/18

- 1 minute read

Jump to:

Step Change in Safety reports an incident in which there was a potential dropped object due to an unsecured door on a load.

What happened?

The incident occurred when a flat pack spooler unit was being lifted from a vessel onto a platform.

What went wrong? What were the causes?

During the lift, the storage door had opened which revealed a small toolbox inside which was not secured.

Actions taken

Secondary retention solution put in place:

Recommended size of the tie wrap is between 4.7mm and 13.2mm for drop locks. Secondary retention must be in place on all units with drop locks for both outward and inward transportation

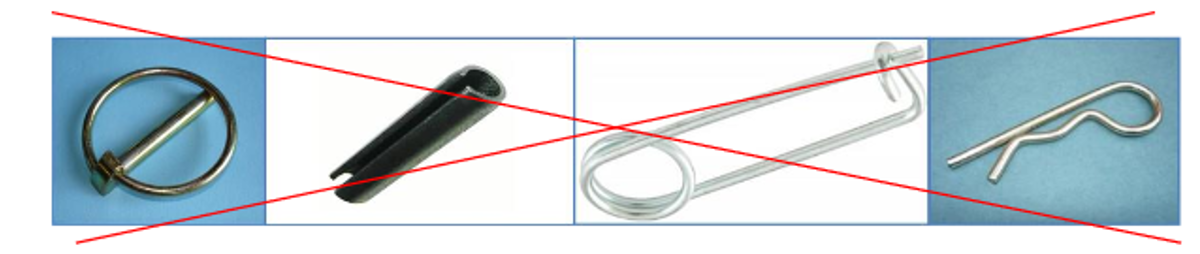

Unsuitable secondary retention methods include linchpins, R-clips, spring/roll/nappy pins or any other type of pin device. All these means of secondary retention for lifting equipment or securing at height can spring open or be knocked out.

Related Safety Flashes

-

IMCA SF 23/16

13 September 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.