Missing protection – progressive wear on hydraulic hoses causes damage

- Safety Flash

- Published on 13 February 2026

- Generated on 13 February 2026

- IMCA SF 03/26

- 2 minute read

Jump to:

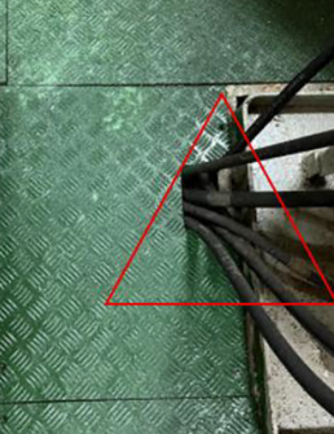

During an inspection, several hydraulic hoses and fuel hoses were found in direct contact with surrounding surfaces and sharp edges.

What happened?

This contact causes friction and progressive hose wear during vessel movement and equipment operation. Visible abrasion marks and missing insulation indicated inadequate hose routing and weak inspection controls. If not rectified, continued wear may have led to hose rupture, hydraulic-oil or fuel leaks, and a significantly elevated fire and machinery-failure risk.

What could have been done better?

- Design and planning: Better, smarter routing of hoses – route hoses with sufficient clearance from structural surfaces or moving components, so that friction/contact points do not occur.

- Installation practices: Take the time, effort and expense to install hoses with proper securing methods;

- Ensure Correct Hose Routing: Hydraulic and fuel hoses should have adequate clearance from sharp edges, moving parts, and structural surfaces. No hose should be left resting against metal components.

- Routine and thorough preventive maintenance: Routine inspections will pick up early wear, missing insulation, or incorrect hose support arrangements – particularly in hot or high vibration environments, or when hoses are exposed to the elements;

- Pay particular attention to high-movement zones and known wear points. Identify early signs of abrasion, missing insulation, loose supports, or rubbing;

- Ensure the person doing the inspection knows what to look for.

- Protective Measures: Hose routings need flanges, chafing guards, protective sleeves or insulation.

- Operational Awareness: Crew could be better aware of the fire, pollution, and equipment-damage risks associated with ongoing hydraulic or fuel hose wear. Hydraulic hoses in particular will move and vibrate during use; this movement should be fully understood and managed.

- IMCA also notes the deck plates illustrated are not secured. i.e. screwed down. International guidelines and codes, such as those from the International Labour Organization, set out standards for flooring to prevent personal injury incidents, requiring that plates are properly fastened and maintained.

- Prevents Trips and Falls: Loose, uneven, or damaged floor plates are a common cause of slips, trips, and falls, which can lead to serious injuries in the busy and complex environment of an engine room.

- Avoids "Missile" Hazards: In the rare but serious event of a crankcase explosion, unsecured plates can be propelled with great force, becoming potential missiles that pose an extreme danger to personnel and equipment.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.