Crane boom dropped object

- Safety Flash

- Published on 19 April 2011

- Generated on 4 March 2026

- IMCA SF 04/11

- 3 minute read

Jump to:

A Member has reported an incident on an offshore construction vessel in which a piece of wood from the main crane boom rest cradle became detached from the cradle and stuck to the crane boom, before falling on to the main deck.

What happened?

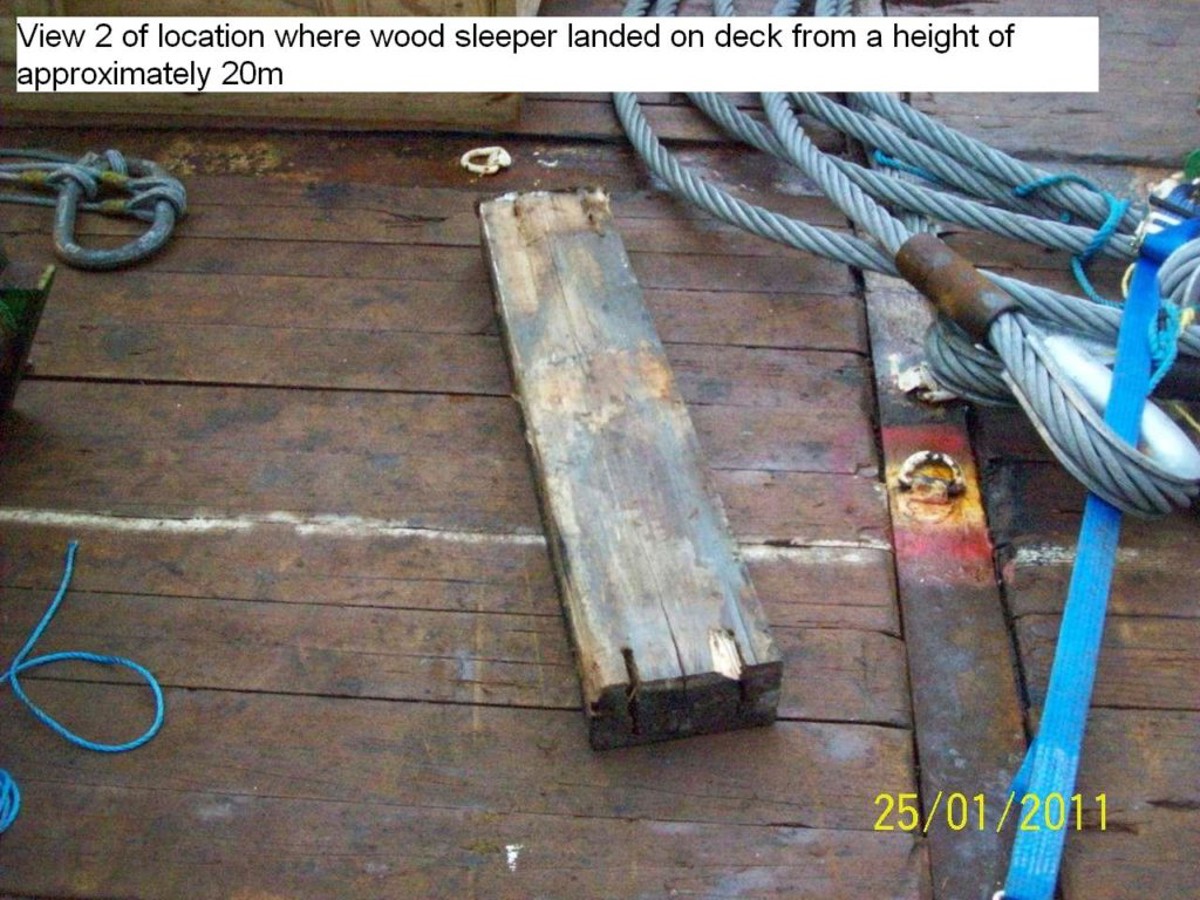

The crane was required for lifts on the main deck and the boom was lifted from its rest cradle on the starboard side of the vessel. The crane boom was then swung into position over the area of the lift on the main deck. A piece of wood from the main crane boom rest cradle had become detached from this cradle and had stuck to the crane boom before falling an estimated 20 metres onto the main deck. There were six people working in the area at the time and the wood landed approximately 1.5 metres from the nearest person. Fortunately no one was injured.

The piece of wood which had been stuck to the crane boom was not noticed by anyone before it fell.

piece of wood dropped from crane boom

What were the causes?

Our Member’s investigation revealed the following:

- The piece of wood was originally secured only by a tack welded strip in position on the crane boom rest.

- Some other fixings for the piece of wood were missing or rusted, and remaining pieces of wood showed signs of deterioration.

- A crane operator had reported verbally to the first engineer approximately one week earlier that the piece of wood in the crane boom rest appeared loose. This report was not made through the normal channels and was not formally recorded on a safety observation card for effective follow up.

- There was a lack of regular inspections to check on the condition of the crane boom rest and fixings.

- A similar incident had occurred on a similar vessel in the previous year, but this incident had not been effectively communicated to the other vessels in the fleet.

Actions

Our Member took the following actions:

- Firmly secured the remaining pieces of wood in the crane boom rest.

- Replaced the existing wood in the crane boom rest with hard wood replacements at the first suitable opportunity, ensuring that these were firmly secured to the crane boom rest.

- Fabricated and installed a suitable and sufficient access ladder and platform to provide safe access for the inspection of the crane boom rest, and included the relevant inspection regime within the vessel’s planned maintenance system.

- Ensured that information about the incident was widely circulated.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.